High-energy laser energy measurement device based on rotating absorber

A high-energy laser and energy measurement technology, applied in measurement devices, optical radiation measurement, radiation pyrometry, etc., can solve problems affecting the accuracy of energy inversion results, increase system complexity, increase structural complexity, etc. Anti-laser damage threshold, prevent heat conduction through the shaft, reduce the effect of average power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

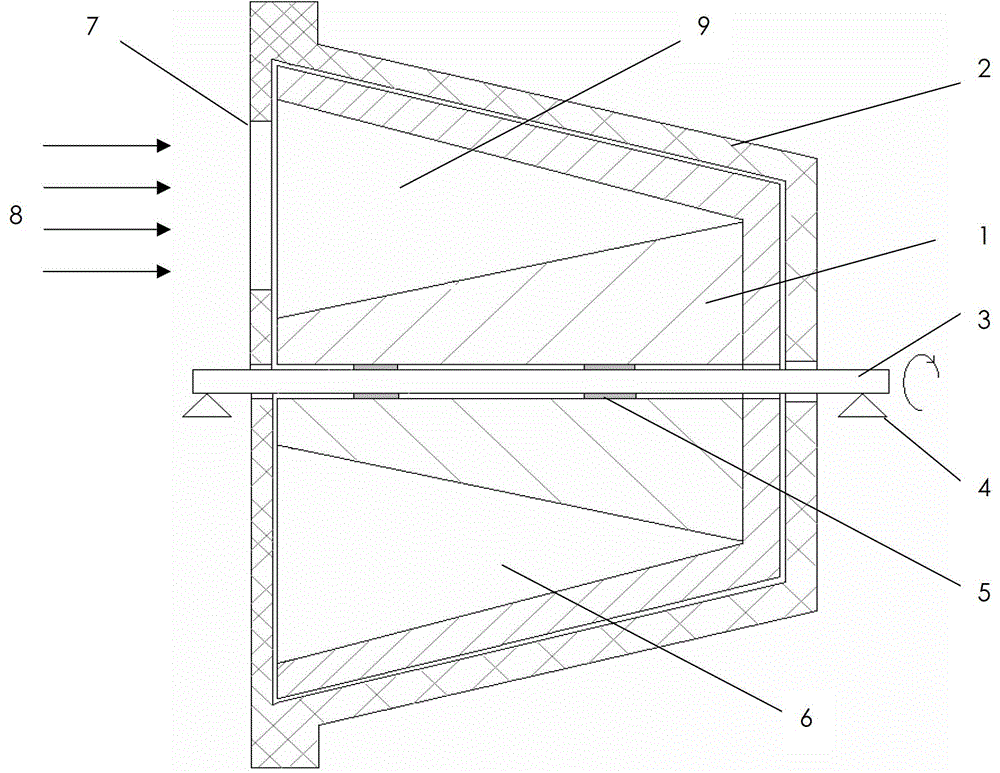

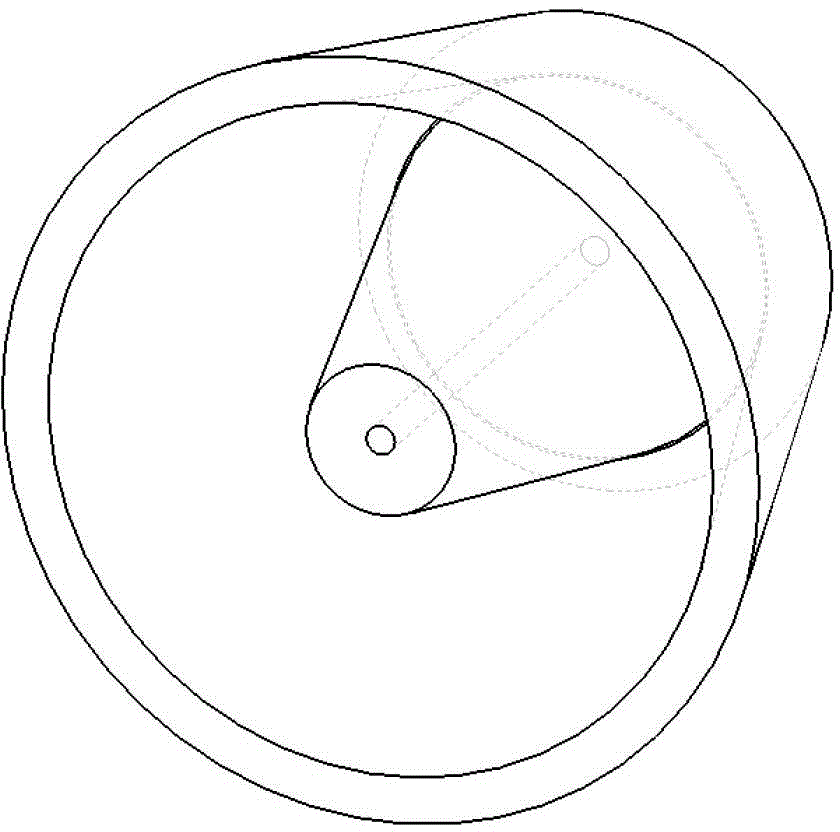

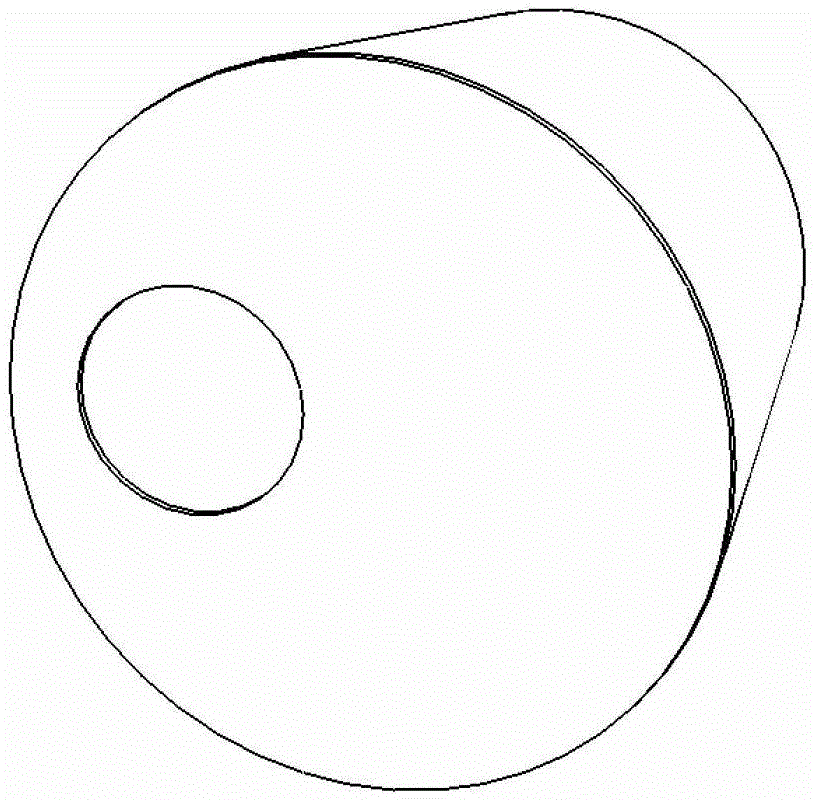

[0030] The present invention provides a laser energy measuring device with high destruction threshold based on the principle of total absorption energy meter. When the incident high-energy laser reaches a photothermal measurement unit, the photothermal measurement unit absorbs the incident laser energy and converts its own temperature rise, and uses a temperature sensor array The temperature change of the photothermal measurement unit is measured in real time. Finally, the data acquisition and processing unit records and processes the temperature signal measured by the temperature sensor array, and finally obtains the total energy of the incident high-energy laser.

[0031] The measurement device of the present invention includes a heat absorber 1, a temperature sensor, and a temperature collection and processing unit. The temperature sensor is a thermoco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com