Underflow-type flow-controllable electric-heating graphite nozzle device of electromagnetic induction slag smelter

An electrothermal and underflow technology, applied in furnaces, furnace components, charge manipulation, etc., can solve problems such as poor fluidity, and achieve the effect of obvious cost advantages, high power factor and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

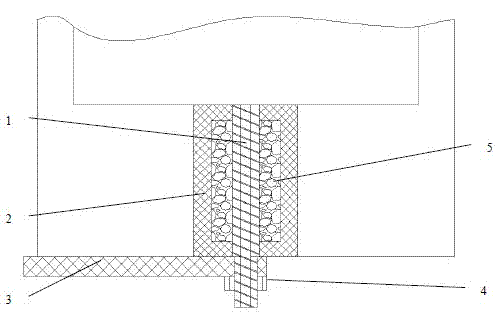

[0033] Control attached image 3 , an underflow flow controllable electrothermal graphite nozzle device used to meet the short process production of rock wool, its structure includes a graphite electric heating spiral tube 1, a graphite sleeve 2, an electric heating tube graphite conductive plate 3, and a graphite nut 4 and refractory filling material 5; wherein the graphite sleeve 2 is fixed on the furnace bottom lining, the upper end of the graphite electric heating spiral tube 1 is connected to the graphite sleeve 2 through threads, and the graphite conductive plate 3 of the electric heating tube is fixed through the graphite The nut 4 is fixed with the graphite electric heating spiral tube 1, and the refractory filler 5 is on both sides of the graphite electric heating spiral tube 1.

[0034] When working: external current → electric heating tube graphite conductive plate 3 → graphite electric heating spiral tube 1 → graphite sleeve 2 → form a loop, making the graphite ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com