Electromagnetic valve for automobile braking system

A solenoid valve and magnetic permeability technology, applied in valve details, valve devices, engine components, etc., can solve the problems of HCU assembly failure and inability to replace it alone, reducing cost and assembly process difficulty, novel structure, and improving yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

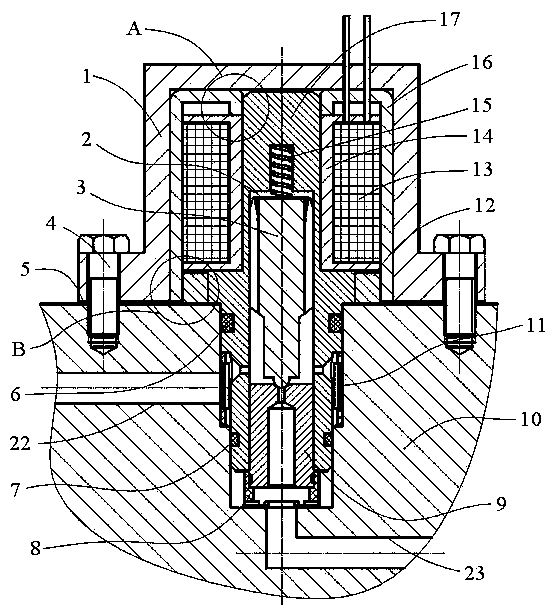

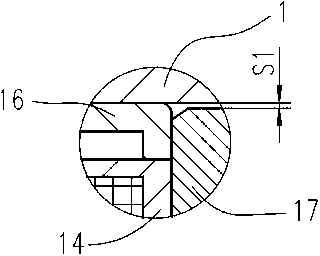

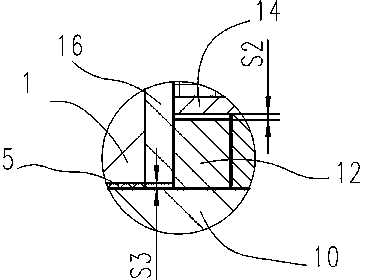

[0012] The gland 1 is fixedly connected to the main valve seat 10 through four uniformly distributed screws 4. There is a sealing gasket 5 between the gland 1 and the main valve seat 10. The gland 1, the magnetically conductive shell 16, the coil support 14, the platform The shoulder 18 and the main valve seat 10 are axially pressed sequentially. There is an axial gap S1 between the top of the solenoid valve body 17 and the gland 1, and there is an axial gap S2 between the upper surface of the magnetic washer 12 and the bottom of the coil support 14. There is a gap S3 between the bottom of the housing 16 and the upper surface 10 of the main valve seat. There is an inward flange 21 at the center hole of the magnetically conductive housing 16 . To the gap fit, the inner ring of the lower part of the magnetic shell 16 is matched with the radial clearance of the outer ring of the magnetic washer 12, the inner ring of the magnetic washer 12 is matched with the outer ring of the shou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com