Heat treatment device and method for high-speed rotor core of dual-performance reluctance motor

A technology of heat treatment device and heat treatment method, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of lack of high-speed motor rotor cores, etc., to prevent oxidation reactions, ensure adjustability and accuracy, and ensure The effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

[0031] An embodiment of the present invention provides a dual-performance reluctance motor rotor core heat treatment device, such as Figure 4 As shown, it includes: heater 2, cooling pipe 3, adapter 4, sealing box interface 5, shielding gas 6, sealing box 7, drive pump 8, radiator 9, pipeline 10, coolant tank 11, heater signal line 12. A first temperature sensor 13 , a sealing ring 14 , a temperature controller 15 , and a second temperature sensor 16 .

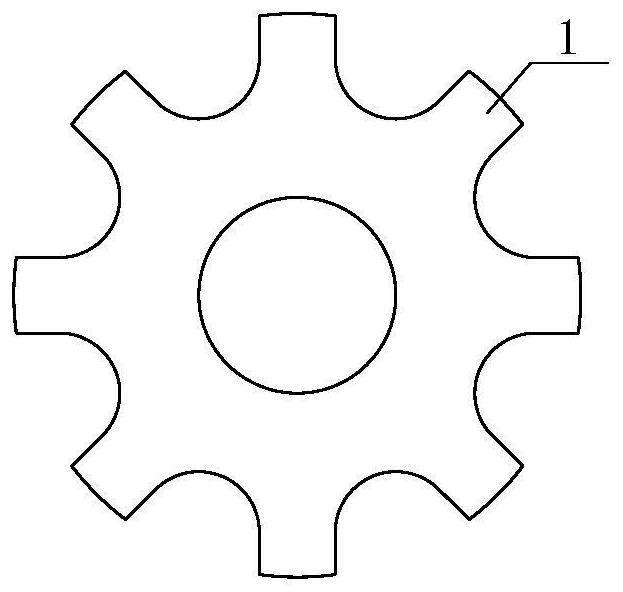

[0032] Iron core to be processed 1 such as figure 1 As shown, the iron-cobalt soft magnetic material is used, and it is arranged in the sealed box 7. The cooling pipe 3 passes through the iron core 1, and the heater 2 is arranged on the circumference of the iron core 1.

[0033] The two ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com