Anchoring construction method for fastener steel tube pile cofferdam

A construction method and technology of steel pipe piles, which are applied in sheet pile walls, foundation structure engineering, buildings, etc., can solve the problems of poor anchorage in overburden waters, large weir body subsidence and deformation, and increased construction costs, so as to improve stability and The effects of safety, shortening the construction period, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

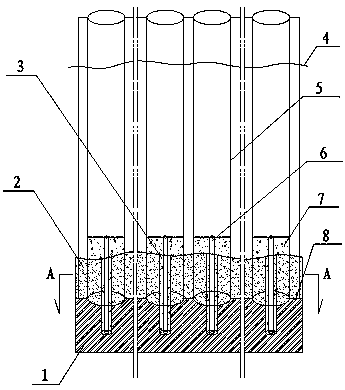

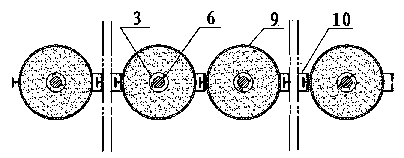

[0015] Below in conjunction with accompanying drawing, the present invention will be further described:

[0016] figure 1 As shown, it is a schematic diagram of the structure of the present invention to effectively consolidate the rock formation and the locking steel pipe pile through the anchor rod; the drilling is carried out in the locking steel pipe pile according to the hole diameter and the anchoring depth, and the anchor rod specifications are selected according to actual requirements to ensure sufficient Strength of. The specific steps are:

[0017] (1) Accurate positioning of the cofferdam of the locking steel pipe pile 5;

[0018] (2) Pass the mobile platform on the water surface 4, hoist and insert and lock the steel pipe pile 5 at an accurate position to pass through the covering layer 2 to the river bed 8;

[0019] (3) Using a mobile platform, use an ordinary geological drilling rig to vertically drill the anchor hole 2 in the overburden layer 2 and the rock la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com