High-strength nickel-saving air valve steel and preparation method thereof

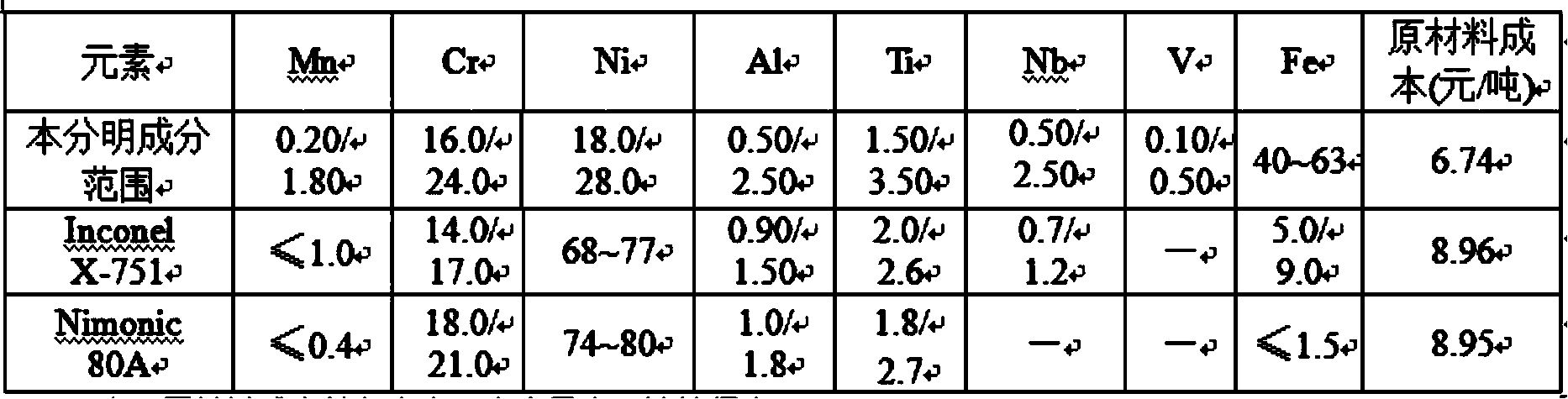

A valve steel, high-strength technology, applied in the field of alloy steel, can solve the problems of restricting application and increasing production costs, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with a typical embodiment.

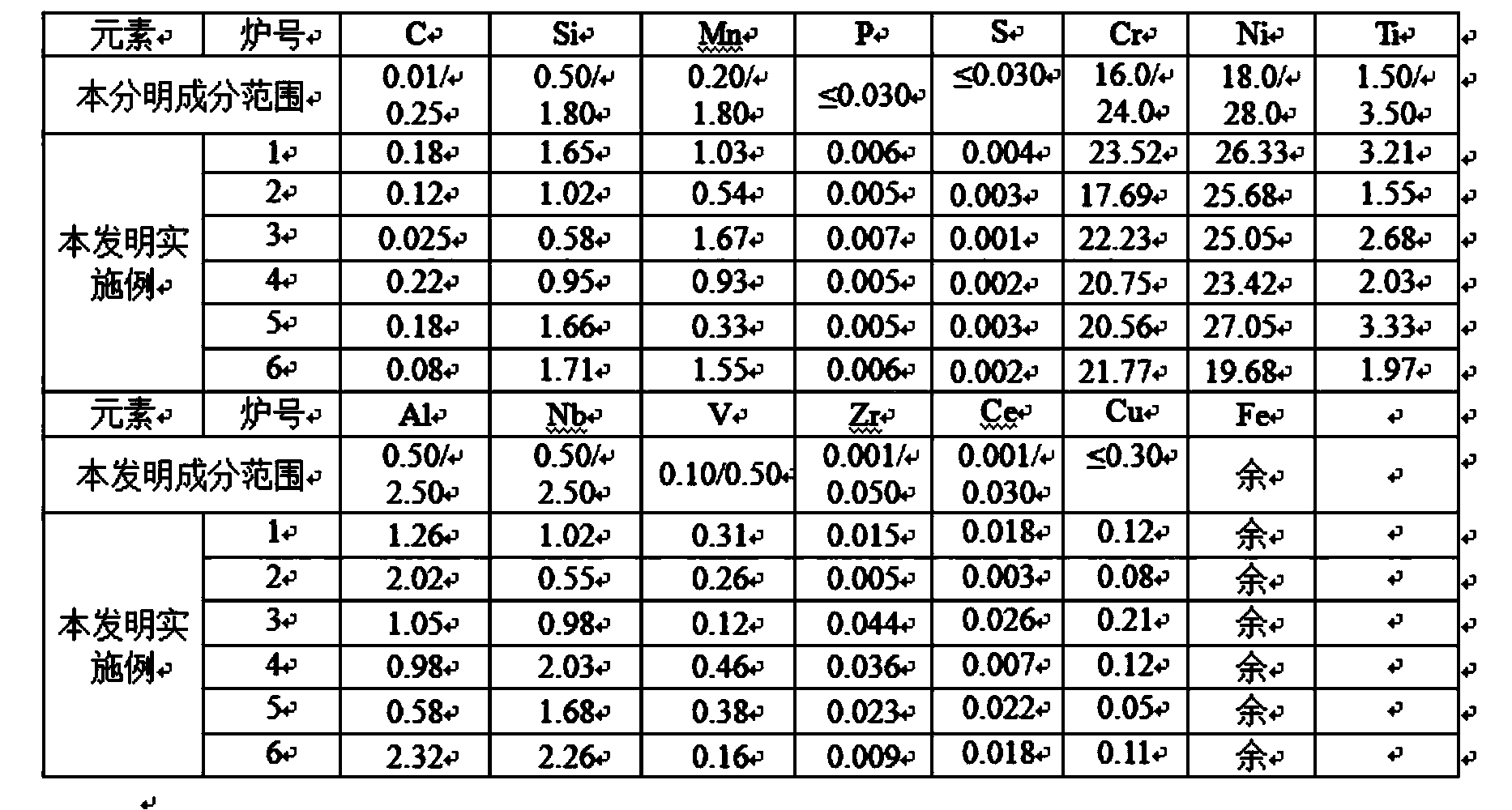

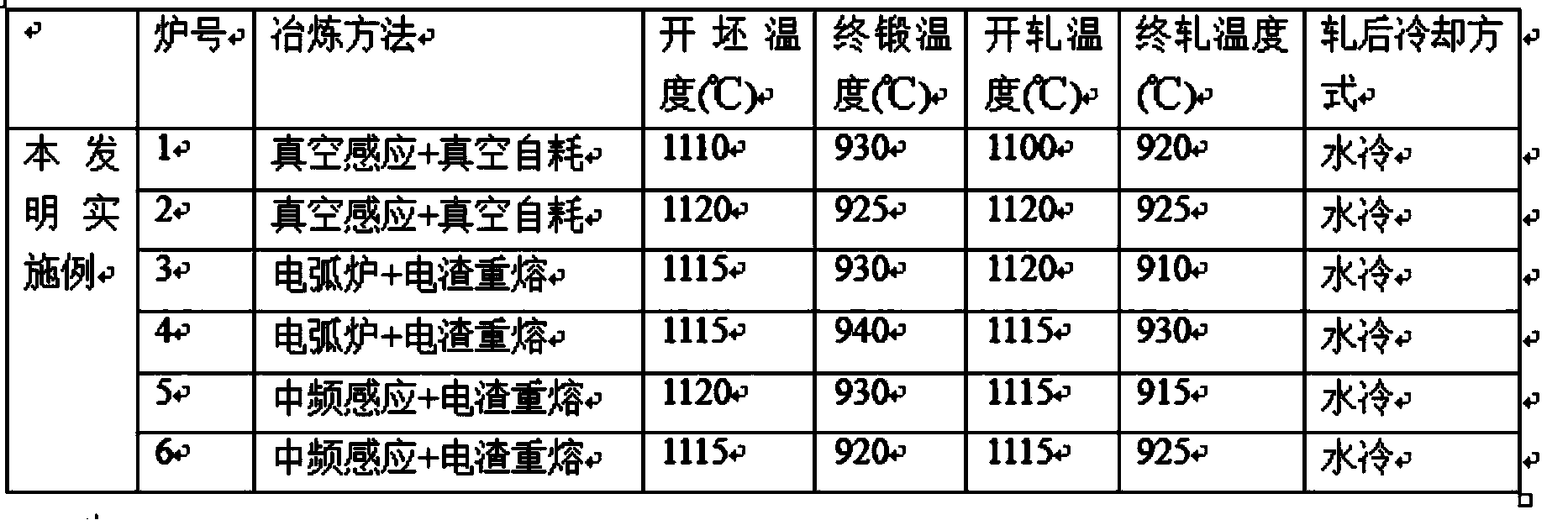

[0015] In this example, a total of 6 furnaces of gas valve steel were smelted, which were smelted by vacuum induction + vacuum self-consumption smelting process, electric arc furnace + electroslag remelting process and intermediate frequency induction furnace + electroslag remelting process. The composition of the gas valve steel in the 6 furnaces is shown in Table 1. First cut the head and tail of the steel ingot to remove the parts with more impurities, and then polish the surface to clean the surface to avoid cracks during forging. The forging blank is carried out on a 2000-ton fast forging machine. The forging blanking temperature is 1100-1120°C, and the final forging temperature is 920-940°C. It is forged into a 140mm×140mm square billet for subsequent hot rolling. The hot rolling temperature is 1100~1120℃, the final rolling temperature is 910~930℃, and the rolling is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fatigue limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com