Cooling liquid for diamond-wire cutting equipment, and preparation method thereof

A cutting equipment, diamond wire technology, applied in the direction of lubricating composition, etc., can solve the problems of poor suspension, high price, poor slicing, etc., and achieve the effect of moderate suspension ability of silicon powder, good cooling effect, and simple production.

Active Publication Date: 2013-11-20

镇江荣德新能源科技有限公司

View PDF5 Cites 25 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The current marketed coolant usually has the following problems during use: (1) The cooling effect is not good

During the cutting process, the temperature of the silicon ingot rises above 30°C. In addition to poor slicing, it is also easy to soften the sticky glue, causing the chips and rods to fall off, causing huge losses.

(2) Suspension of silicon powder is too good or too poor

If the suspension is too good, the silicon powder will easily enter the slit repeatedly with the coolant, which will reduce the cutting efficiency of the diamond wire and cause poor TTV; if the suspension is too poor, the silicon powder will easily deposit on every corner of the equipment, especially In the plate heat exchanger, the heat exchange between the coolant and the process cooling water is poor, and the temperature of the coolant cannot be effectively reduced, resulting in poor cutting

(3) It is easy to generate air bubbles during recycling

During the cutting process, a large number of air bubbles exist on the surface of the diamond wire, which greatly reduces the cooling liquid that actually participates in cooling and suspension, resulting in uneven temperature distribution on the surface of the silicon wafer, which is prone to defects such as debris and line marks.

(4) Part of the acidic coolant is easy to corrode the steel wire

Most of its products are imported products with high prices. In order to further realize clean production, reduce costs, and improve cutting quality, a new localized cooling fluid is needed to meet the requirements of diamond wire cutting monocrystalline silicon.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

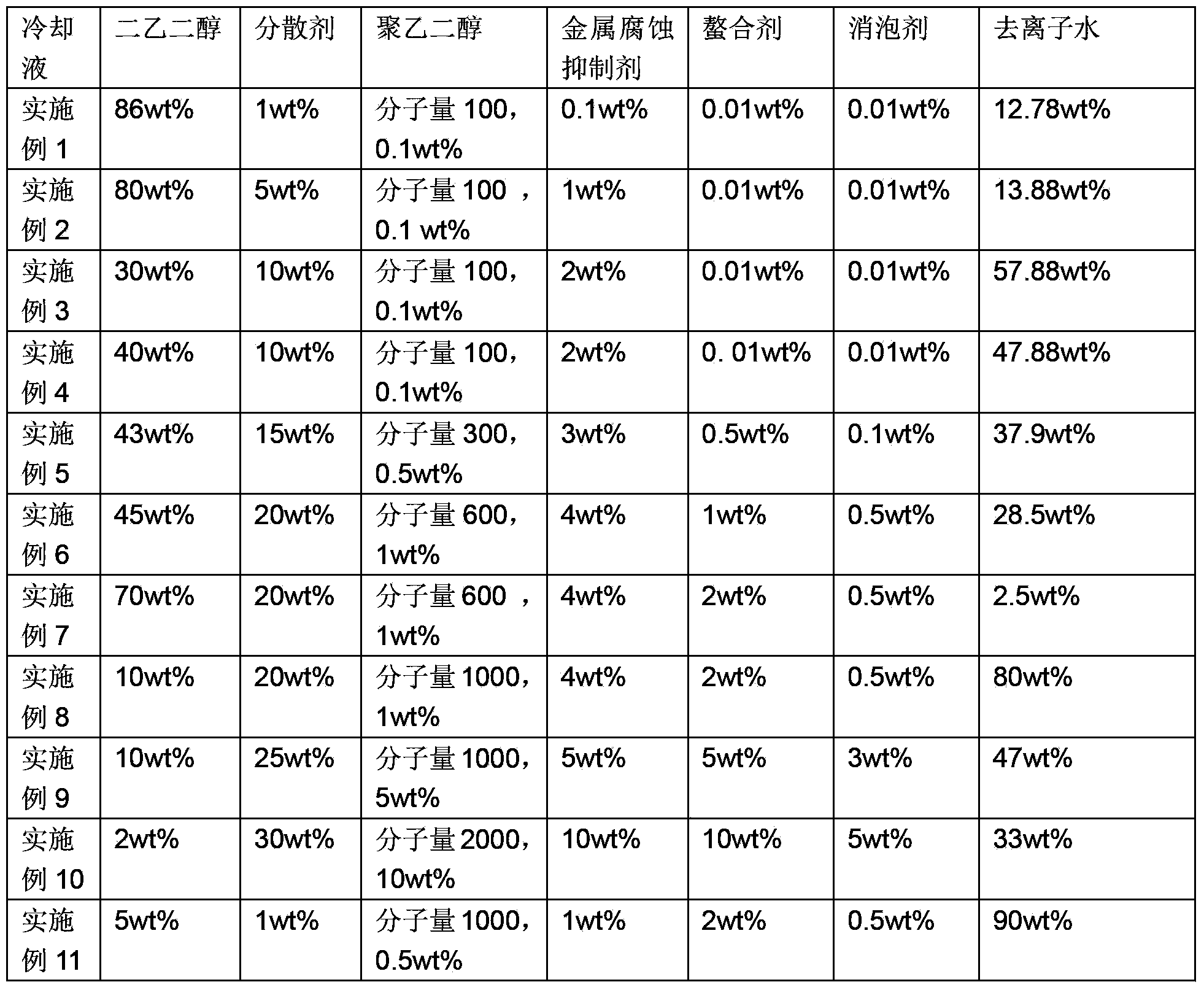

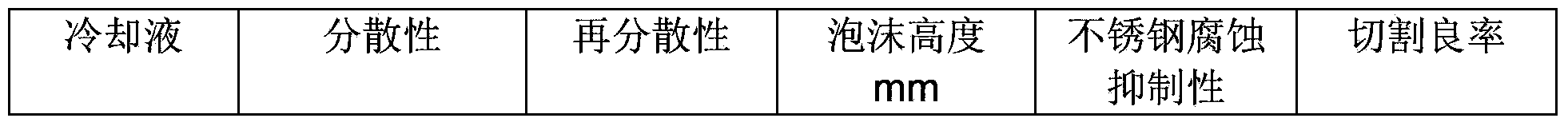

Embodiment 3-7

[0051] In said embodiment 3-7:

[0052] Dispersant: select the mixture of diethylene glycol, ethylene glycol methyl ether, and ethylene oxide obtained through homopolymerization;

[0053] Metal corrosion inhibitor: use benzotriazole;

[0054] Chelating agent: use ethylenediaminetetraacetic acid;

[0055] Defoaming agent: use organosiloxane.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a cooling liquid for diamond-wire cutting equipment, and a preparation method thereof. The cooling liquid consists of: 2.5 wt%-90 wt% of deionized water, 2 wt%-86 wt% of diethylene glycol, 0.1 wt%-10 wt% of polyethylene glycol with an average molecular weight of 100-2000, 1 wt% -30 wt% of a dispersant, 0.01 wt% -10 wt% of a chelating agent, 0.1 wt% -10 wt% of a metal corrosion inhibitor and 0.01 wt% -5 wt% of an antifoaming agent. The preparation method comprises: successively adding the chelating agent, the metal corrosion inhibitor and the antifoaming agent into deionized water according to the ratio, uniformly stirring; and then adding diethylene glycol, the dispersant and polyethylene glycol, stirring for 6-8 hours to prepare the cooling liquid for the diamond-wire cutting equipment. The cooling liquid for the diamond-wire cutting equipment has the characteristics of good cooling effect, moderate silicon-powder suspension capability, low viscosity, few foams and low corrosivity, and is simple in manufacture and low in cost.

Description

technical field [0001] The invention relates to a cooling liquid used in a silicon wafer cutting process, in particular to a cooling liquid used for diamond wire cutting single crystal silicon. Background technique [0002] At present, the materials used in solar photovoltaic cells mainly include amorphous silicon, polycrystalline silicon, single crystal silicon, and III-V compound compounds. Among them, monocrystalline silicon has high photoelectric conversion efficiency, the material itself does not pollute the environment, has a wide range of material sources, and has stable performance. In the manufacturing process of monocrystalline silicon cells, it is necessary to cut the Czochralski monocrystalline silicon rod into silicon wafers with a thickness of about 200um. [0003] Now there are mainly two ways of cutting: mortar multi-wire cutting and diamond wire multi-wire cutting. Compared with mortar cutting, diamond wire cutting has the characteristics of high cutting e...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M173/02C10M169/04

Inventor 刘瑞鸿孙培亚钱珊珊邢旭

Owner 镇江荣德新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com