Method for granulating sludge based on pure-oxygen aeration-treated urban sewage

A technology for sludge granulation and domestic sewage, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of long activated sludge granulation cycle and small sludge particle size , shortening the cultivation time and other issues, to achieve the effects of easy large-scale promotion, increasing particle size and shortening the cultivation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

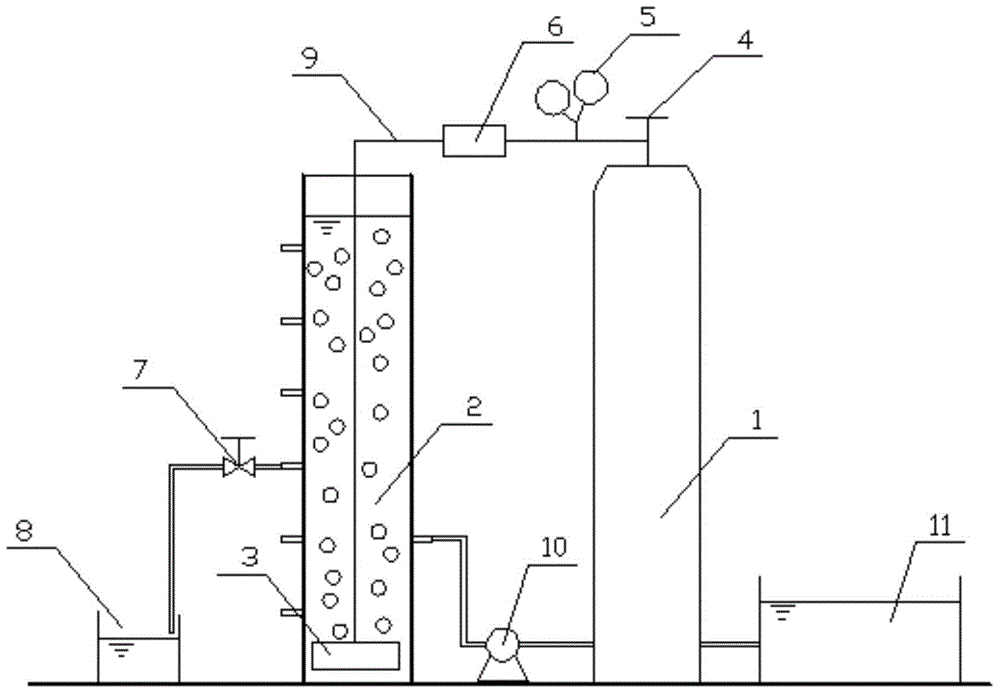

[0019] In this example, the method based on pure oxygen sludge granulation of urban domestic sewage adopts a sequencing batch reactor 2 (SBR) with an aspect ratio of 10. The main part of the column is cylindrical, with an inner diameter of 0.1m and an outer diameter of 0.12 m, the height is 1.0m. The bottom of the reactor 2 is provided with a microporous aeration head 3, the microporous aeration head 3 is connected with the oxygen cylinder 1 through the aeration pipe 9, the aeration pressure is controlled by the pressure reducing valve 5, and the aeration volume is controlled by the rotameter 6 Control and adjustment, the raw water in the water tank 11 is poured into the reactor 2 through the water inlet pump 10 for sludge cultivation, the reactor is controlled by the solenoid valve 7 to drain to the secondary sedimentation tank 8, the aeration period is controlled by the air inlet valve 4, and the aeration cycle is controlled by the water inlet pump 10 Control the water intak...

Embodiment 2

[0024] The difference between this example and Example 1 is that the method based on the granulation of pure oxygen sludge from urban domestic sewage uses a sequencing batch reactor (SBR) with a height-to-diameter ratio of 11. The inner diameter of the column is 0.1m, and the outer diameter is 0.11m, height 1.1m; in the second stage of sludge granulation cultivation, COD, ammonia nitrogen, total phosphorus, and calcium ion concentrations reached 600mg / L, 100mg / L, and 9mg / L respectively; during the cultivation period, the calcium ion concentration was 100mg / L; The fourth stage of granulated sludge cultivation takes 6 days to form granulated sludge.

Embodiment 3

[0026] The difference between this example and Example 1 is that the method based on the granulation of pure oxygen sludge from urban domestic sewage adopts a sequencing batch reactor (SBR) with a height-to-diameter ratio of 12.5, the inner diameter of the column is 0.08m, and the outer diameter is 0.09m, height 1.0m; in the second stage of sludge granulation cultivation, COD, ammonia nitrogen, total phosphorus, and calcium ion concentrations reached 800mg / L, 120mg / L, and 10mg / L respectively; during the cultivation period, the calcium ion concentration was 120mg / L; The fourth stage of granulated sludge cultivation takes 3 days to form granulated sludge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com