Environmentally-friendly dedusting ash processing apparatus

A processing device and environmental protection technology, applied in the field of environmental pollution control by physical methods, can solve the problems of polluting the surrounding air, difficult loading of ash powder, and polluting urban roads, etc., to achieve simple process flow, solve secondary pollution, and solve difficult cleaning problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

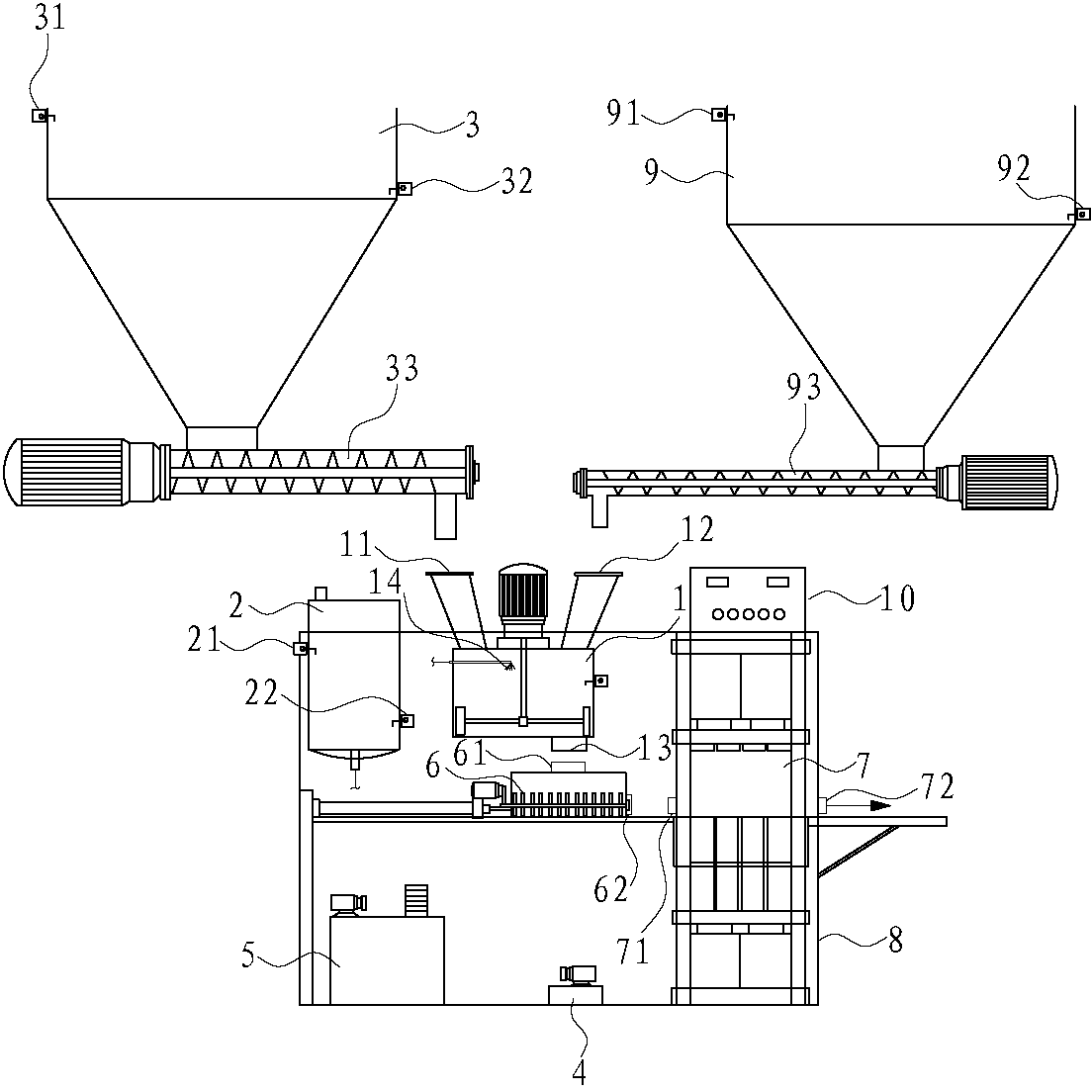

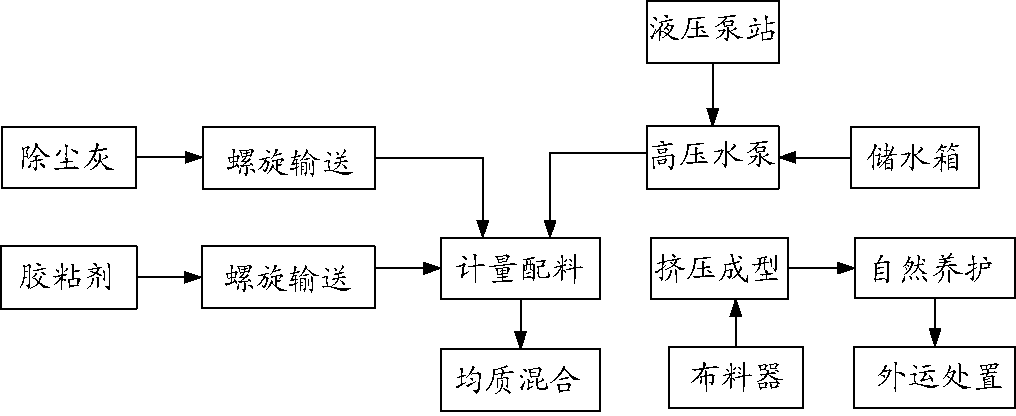

[0015] Such as figure 1 As shown, an environmentally friendly dust removal treatment device disclosed by the present invention includes a metering and proportioning mixer 1, a water storage tank 2, a sprinkler head 14, a high-pressure water pump 4, a hydraulic pump station 5, a distributor 6, an extrusion molding machine 7, and a casing 8 and electric control cabinet 10.

[0016] A metering mixer 1, a water storage tank 2, a sprinkler head 14, a high-pressure water pump 4, a hydraulic pump station 5, a distributor 6 and an extrusion molding machine 7 are installed in the shell 8, and the electric control cabinet 10 is installed on the shell 8.

[0017] A dust removal ash inlet 11 and an adhesive inlet 12 are provided on the top of the metering and proportioning mixer 1 , while a material outlet 13 is provided below, and a spray head 14 is installed inside the dust removal ash inlet 11 .

[0018] The spray head 14 is connected to the water storage tank 2 through the high-press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com