Simple device for assembling pressure steel pipe stiffening ring

A pressure steel pipe and stiffening ring technology, applied in the field of simple devices, can solve the problems of damage to the base material, the appearance of deep pits, and the reduction of thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be specifically described below in conjunction with the accompanying drawings.

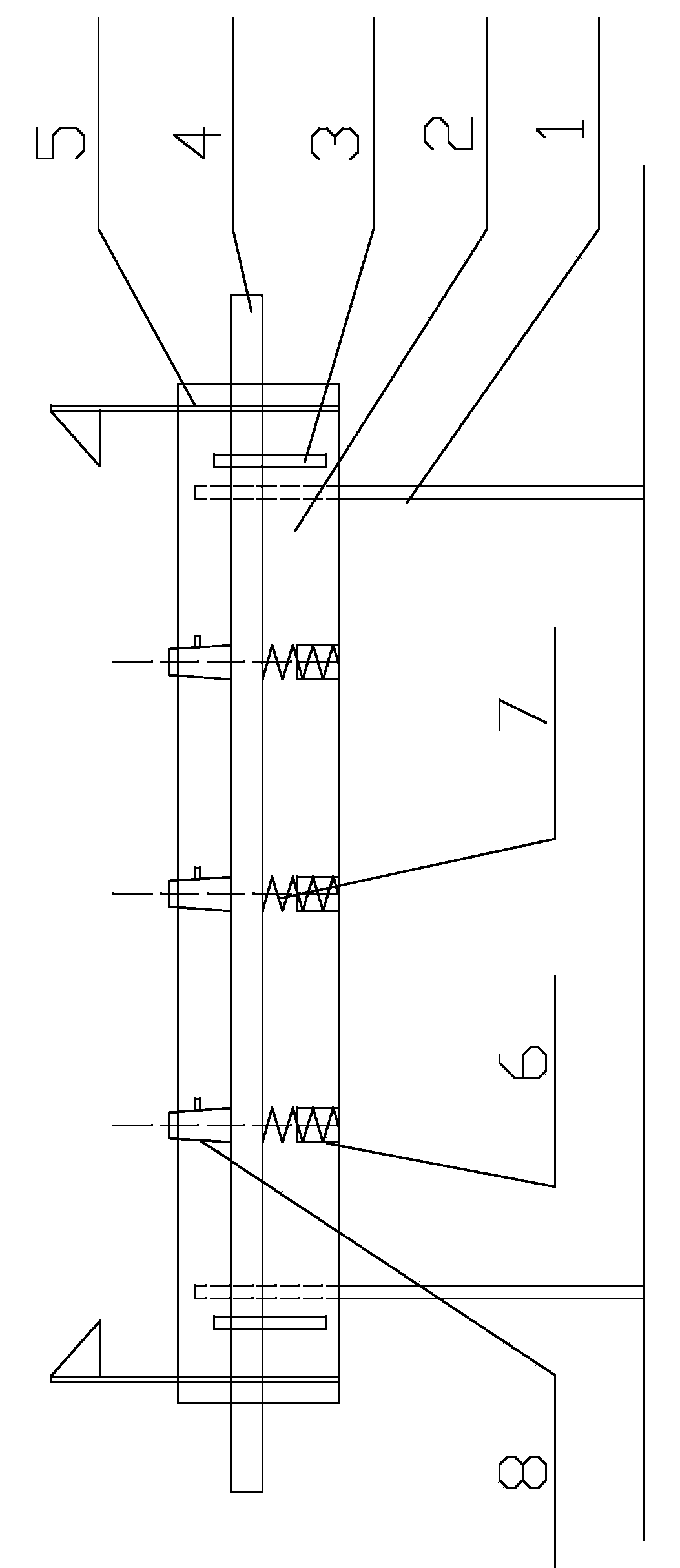

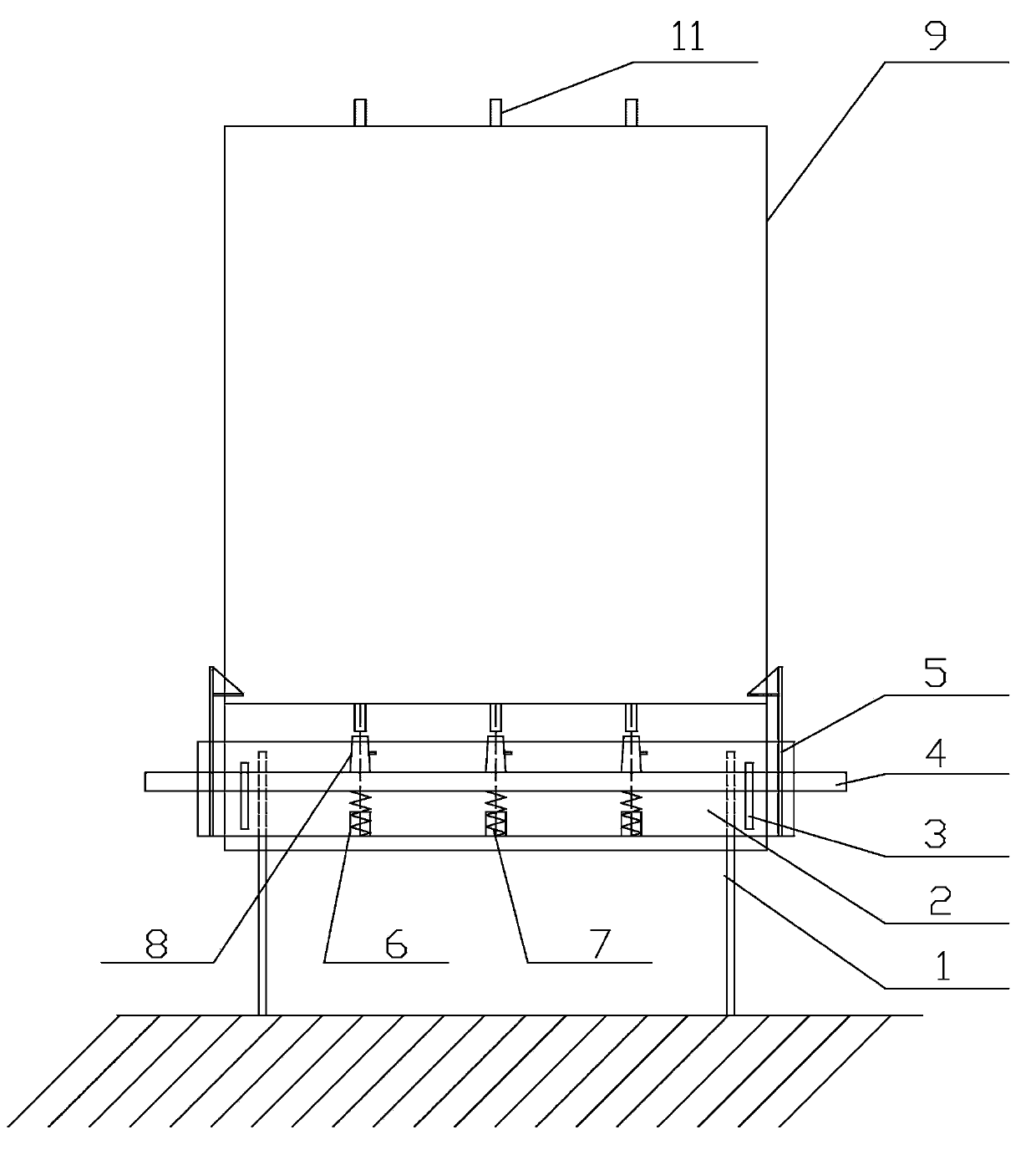

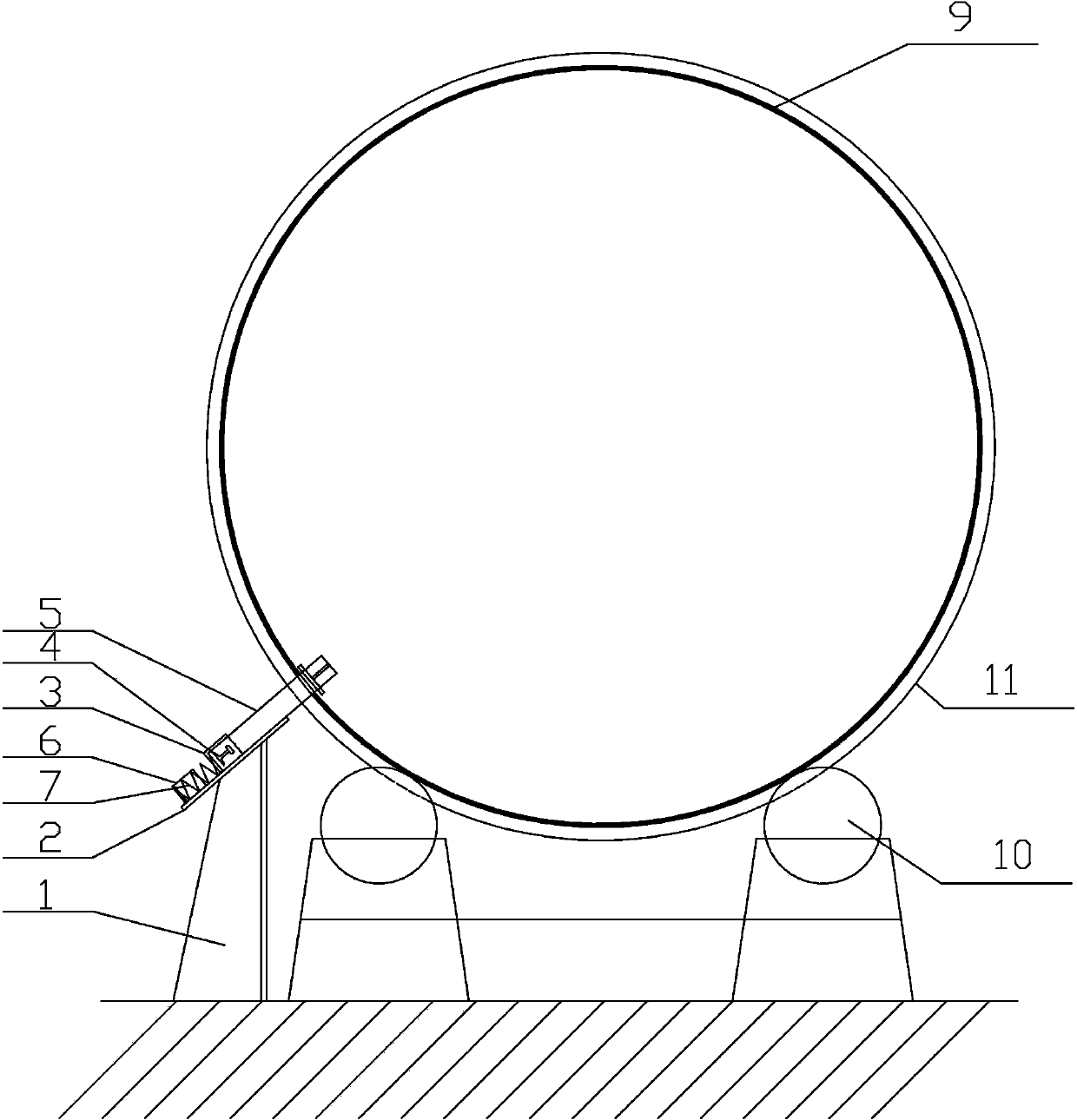

[0011] A simple device for assembling stiffening rings of penstock steel pipes, such as figure 1 As shown, it is composed of column 1, support panel 2, track fixing frame 3, track 4, side pull plate 5, bushing 6, spring 7 and jack 8, wherein: column 1 is welded by steel plate, column 1 and support The panels 2 are welded together, the supporting panel 2 and the track fixing frame 3 are welded together to form a whole, the track 4 is fixed on the supporting panel 2 through the track fixing frame 3, one end of the side pull plate 5 is sleeved on the track 4, and the other end is on the When working, the inner wall of the steel pipe 9 is tightened, the casing 6 is welded with the support panel 2, the spring 7 is placed in the casing 6, and plays a supporting role for the track 4, and the jack 8 is placed on the track 4, not in contact with the track 4. connect. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com