Molten salt battery and method for producing same

A molten salt battery, molten salt technology, applied in the direction of molten electrolyte, secondary battery, airtight storage battery, etc., can solve the problem of discharge shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

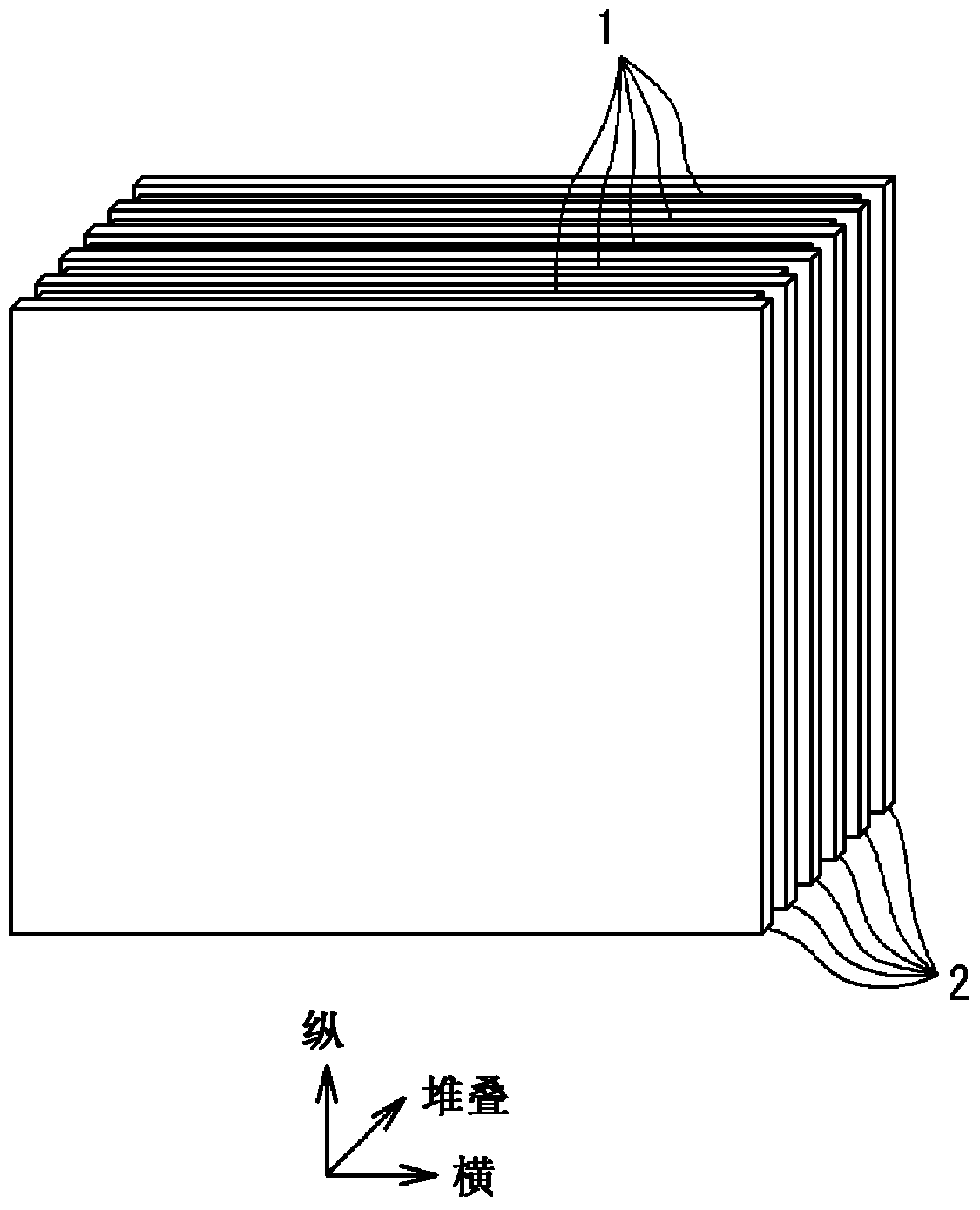

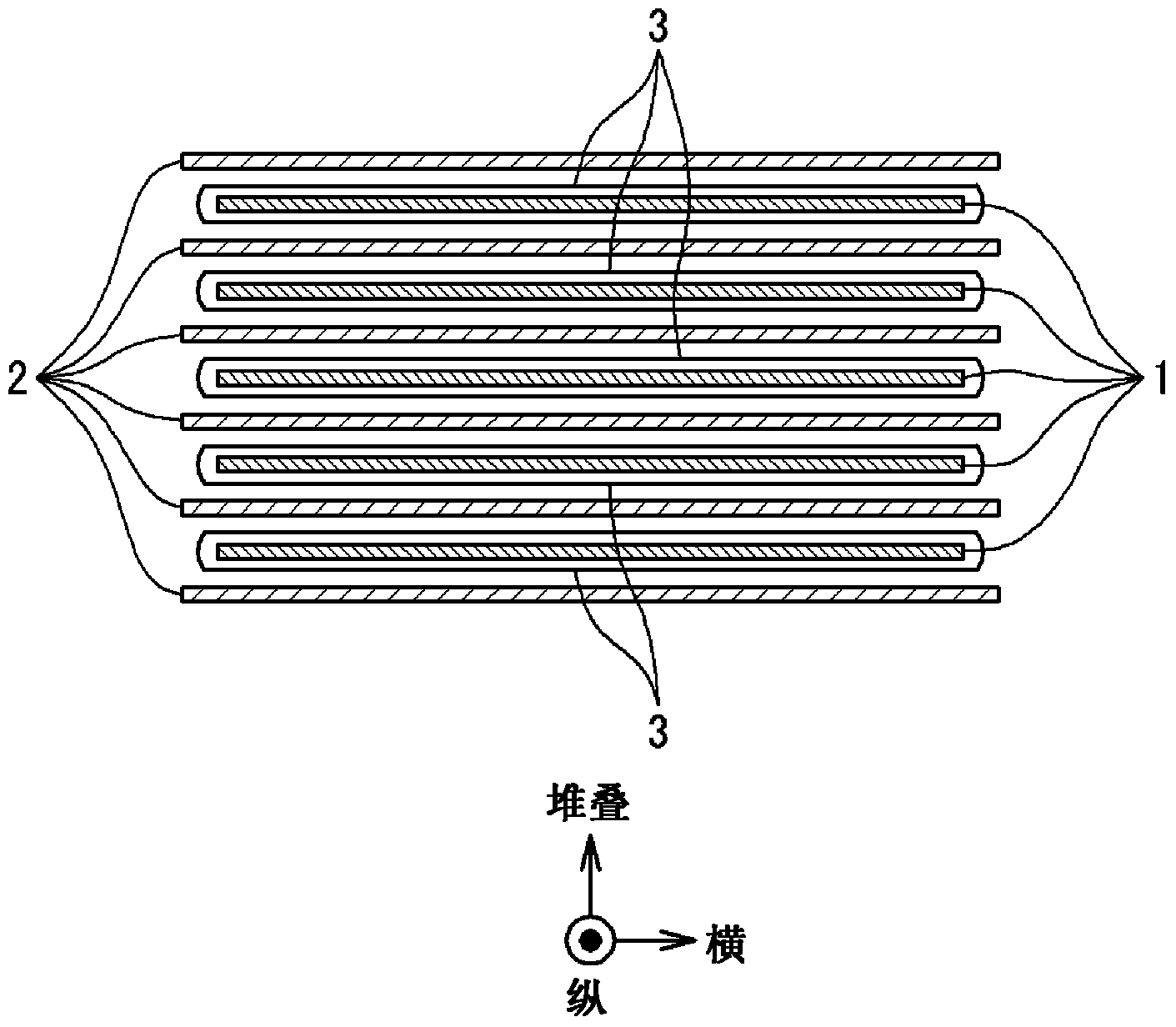

[0035] A molten salt battery according to one embodiment of the present invention will be described below with reference to the drawings.

[0036] figure 1 It is a schematic diagram schematically showing the basic structure of a power generating element in a molten salt battery. In the drawing, the power generating element includes a positive electrode 1, a negative electrode 2, and a separator 3 disposed therebetween. The positive electrode 1 includes a positive electrode current collector 1a and a positive electrode material 1b. The negative electrode 2 includes a negative electrode current collector 2a and a negative electrode material 2b.

[0037] The material of the positive electrode current collector 1 a is, for example, aluminum nonwoven fabric (wire diameter: 100 μm, porosity: 80%). By using a mass ratio of 85:10:5:50 to positive electrode active materials such as NaCrO 2, acetylene black, PVDF (polyvinylidene fluoride) and N-methyl-2-pyrrolidone were mixed to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com