Positive-acting photosensitive composition and hardened material thereof

A photosensitive composition, positive-type technology, applied in the processing of photosensitive materials, silicon organic compounds, compounds of elements of Group 4/14 of the periodic table, etc., can solve the problem of easy peeling, too much, and narrow development latitude and other problems, to achieve the effect of excellent chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

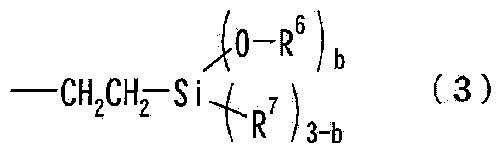

Method used

Image

Examples

Embodiment

[0201] Hereinafter, examples are given to further illustrate the present invention, but the present invention is not limited by them.

[0202] In addition, the content of the silanol group was determined as follows: the sample was reacted with trimethylchlorosilane in a pyridine solution to change the silanol group to a trimethylsilyl ether group, and then tetramethylhydrogen Ammonium oxide ((CH 3 ) 4 NOH) The aqueous solution is treated to hydrolyze the C—O—Si bond, and the mass increase rate after the reaction is calculated backward to obtain the silanol group content.

manufacture example 1

[0203] Production Example 1: Intermediate a1

[0204] In a glass reaction vessel equipped with a thermometer and a stirring device, 300 g of toluene as a solvent, 240 g (1 mol) of 2,4,6,8-tetramethylcyclotetrasiloxane, and 64.1 g of tert-butyl acrylate ( 0.5 mol), 352 g (2 mol) of 4-tert-butoxystyrene, and 0.05 g of platinum-divinyl tetramethyl disiloxane complex (Karstedt catalyst) as a catalyst, while stirring at 60°C After reacting for 10 hours, the solvent was distilled off to obtain intermediate a1. Intermediate a1 is the compound (R 1 = Methyl, R 2 =R 3 = Ethylene, Pg=tert-butyl, m=0.5, n=2, p=1.5, m:n:p=1:4:3).

manufacture example 2

[0205] Production Example 2: Intermediate a2

[0206] In Production Example 1, 102 g (0.5 mol) of tert-butyl 4-vinylbenzoate was used instead of 64.1 g (0.5 mol) of tert-butyl acrylate. The same operation as in Production Example 1 was performed except that the intermediate 体a2. Intermediate a2 is the compound (R 1 = Methyl, R 2 =2-phenylethane-1,4'-diyl, R 3 = Ethylene, Pg=tert-butyl, m=0.5, n=2, p=1.5, m:n:p=1:4:3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com