General mask and application thereof

A mask plate and lithography machine technology, which is applied to the photolithography process of the pattern surface, the original used for photomechanical processing, and the photolithography process exposure device, etc., can solve the problem of not providing a lithography machine mask, etc. fully compatible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

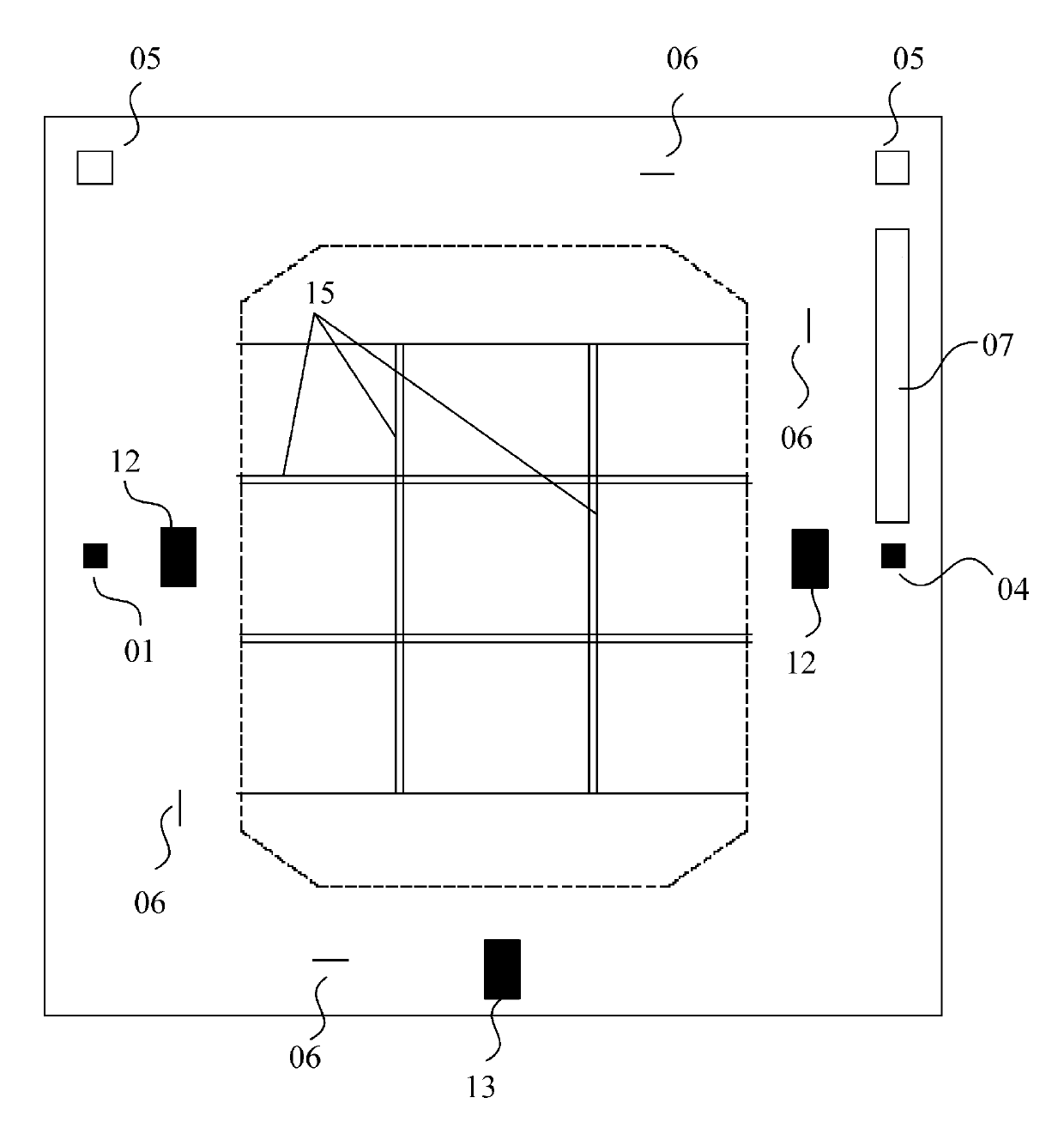

[0021] A pre-designed circuit pattern is printed on the mask plate, through which ultraviolet light shines on the photoresist layer on the wafer to form the circuit pattern of the microprocessor. On a mask plate, in addition to the designed circuit layer graphics, plate alignment marks, silicon wafer coarse alignment marks, silicon wafer fine alignment marks, plate names, numbers and barcodes for automatic identification will be placed at appropriate positions.

[0022] figure 1 Shown is a reticle for ASML on which a part of the above is schematically marked. Among them, reference numerals 01, 02, 03, and 04 represent reticle alignment marks, reference numeral 05 represents reticle pre-alignment marks, and reference numerals 06 denotes a pellicle position line, and reference numeral 07 denotes a barcode. The distance between reticle alignment marks 02 and 03 is 96±0.00015mm, and the distance between reticle alignment marks 01 and 04 is 111±0.00015mm.

[0023] The alignment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com