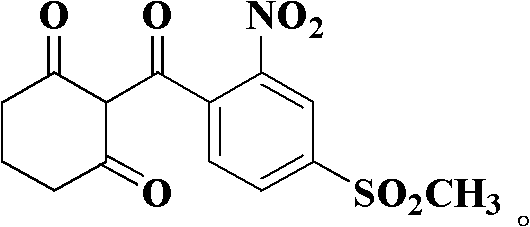

Method for preparing mesotrione with stable crystal form

A technology of stable mesotrione and mesotrione, which is applied in the field of preparation of stable crystalline mesotrione, can solve the problems of increasing the pressure and investment of three wastes treatment, the thermal decomposition of mesotrione crystallization, and the increase of unknown impurity content. Significant significance, reduced energy consumption, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1 Add denaturant without adding defoamer

[0016] Take 300g of mesotrione potassium salt solution, add 1.5g of dichloromethane, control the temperature at 35-45°C, slowly add hydrochloric acid dropwise until pH=2-2.5, and add dropwise for about 0.5 hours. After the acidification is finished, adjust the vacuum degree of the system to 0.09Mpa, and carry out vacuum distillation at a temperature of 35-45°C. A large amount of foam is produced during the distillation process, the distillation speed is controlled to avoid flushing, and the vacuum distillation is stopped after 15 g of fractions are evaporated, and the distillation time is 8 hours. Cool down to 10-15°C, filter and wash to obtain mesotrione crystals with a yield of 97.2%, and the content of unknown impurities in the product is 1.2%. Analysis showed that the solid crystallized as Mesotrione Form I.

Embodiment 2

[0017] Embodiment 2 Add denaturing agent and defoamer

[0018] Take 300g of mesotrione potassium salt solution, add 0.3g of 1,1-dichloroethane, control the temperature at 35-45°C, slowly add hydrochloric acid dropwise until pH=2-2.5, and add dropwise for about 0.5 hours. After acidification, add 0.05g of soybean oil, adjust the vacuum degree of the system to 0.09Mpa, and carry out vacuum distillation at a temperature of 35-45°C. During the distillation process, the foam height is 6 mm, and the defoaming time is less than 5 seconds. After 15 g of distillate is evaporated, the vacuum distillation is stopped, and the distillation time is 45 to 55 minutes. Cool down to 10-15°C, filter and wash to obtain mesotrione crystals with a yield of 98.5%, and the content of unknown impurities in the product is 0.07%. Analysis showed the crystals to be Mesotrione Form I.

Embodiment 3

[0019] Embodiment 3 Add denaturing agent and defoamer

[0020] Take 300g of mesotrione potassium salt solution, add 0.03g of dichloroethane, control the temperature at 35-45°C, slowly add hydrochloric acid dropwise until pH=2-2.5, and add dropwise for about 0.5 hours. After acidification, add 0.015g of soybean oil, adjust the vacuum degree of the system to 0.09Mpa, and carry out vacuum distillation at a temperature of 35-45°C. The foam height is 10 mm, the defoaming time is less than 7 seconds, and the vacuum distillation is stopped after 15 g of distillate is evaporated, and the distillation time is 45 to 55 minutes. The temperature was lowered to 10-15°C, filtered and washed to obtain mesotrione crystals with a yield of 98.3%, and the content of unknown impurities in the product was 0.09%. Analysis showed that the resulting crystalline solid was Form I of mesotrione.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com