Method for making glass substrate for display, glass substrate and display panel

A technology of glass substrate and manufacturing method, which is applied in the field of display panels, can solve problems such as TFT damage, peeling, and wiring pattern defects, and achieve the effect of suppressing static electricity and suppressing static electricity damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

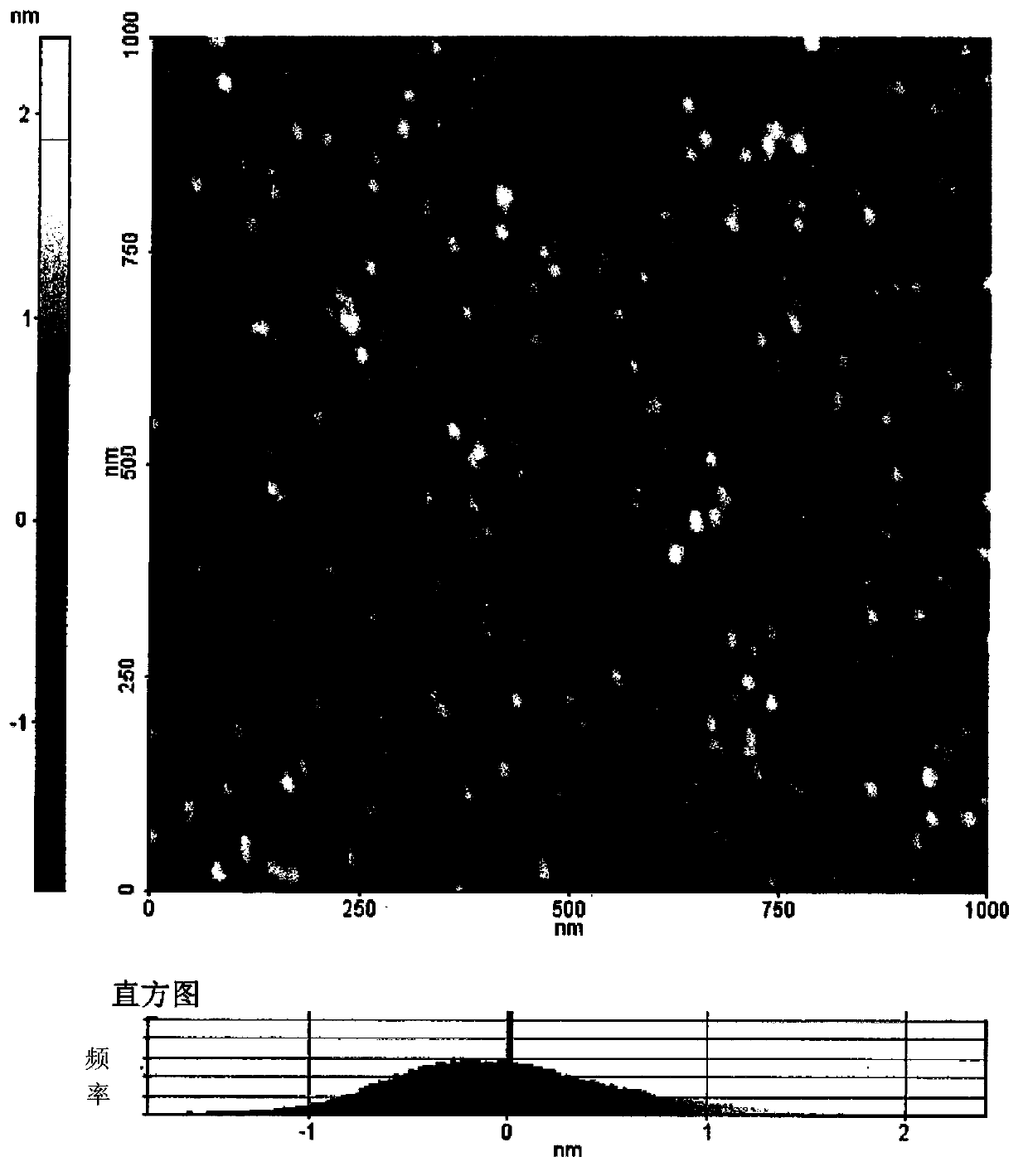

[0116] In order to examine the effect of this embodiment, the glass substrate for liquid crystal display devices using boroaluminosilicate glass was produced.

[0117] (rough surface treatment)

[0118] The above-mentioned atmospheric pressure plasma cleaning was performed on the produced glass substrate. That is, the plasma state of N 2 , O 2 The mixed gas flows to the entire width of the glass substrate at a specified amount per minute to clean the glass surface of the glass substrate.

[0119] Further, use Image 6 The etching apparatus 30 shown performs etching. In the etching device 30, the etching is performed by flowing a radicalized etching gas HF, which makes CF 4 、H 2 The mixed gas of O is obtained in plasma generated using a rare gas or the like.

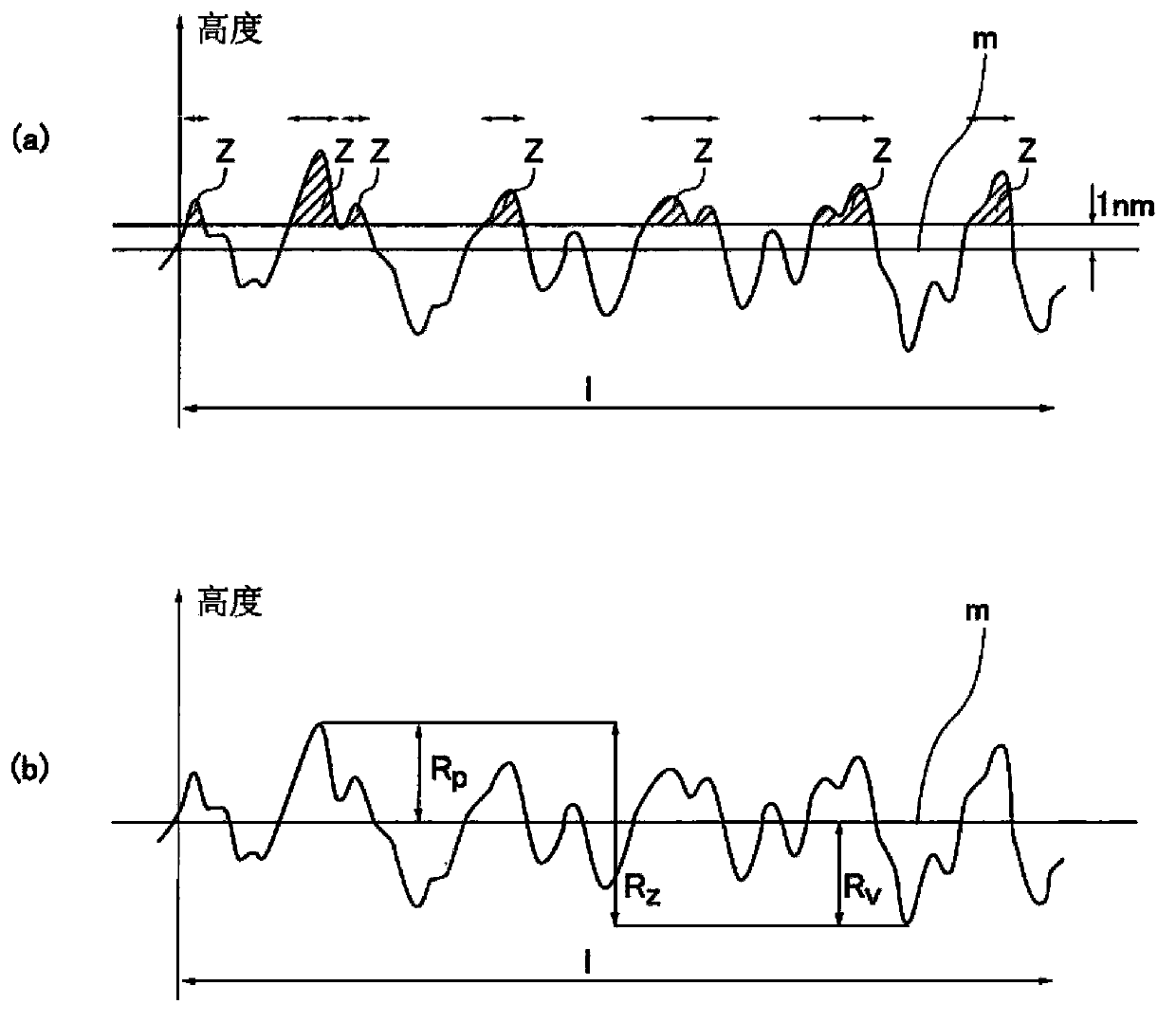

[0120] Samples 1 to 8 shown in Table 1 below are for CF 4 、H 2 The supply of O, and the addition to CF 4 、H 2 The type of carrier gas in the mixed gas of O (N 2 or Ar gas) to variously change the shape of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com