Electroformed nickel-iron alloy screen plate for printing and preparation method thereof

A nickel-iron alloy and iron alloy technology, applied in the field of electroforming alloy co-deposition, can solve the problems of limited prospect of electroformed nickel stencils, poor stability of electroformed nickel baths, and high cost of electroformed nickel, so as to reduce the burden of three-waste treatment and reduce the cost of electroforming nickel. The effect of good brightness, surface quality and opening quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

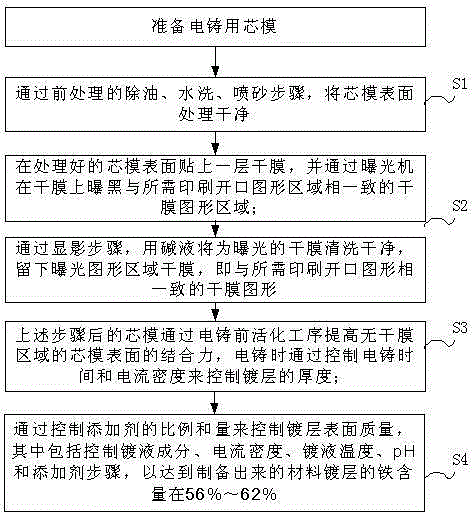

Method used

Image

Examples

Embodiment Construction

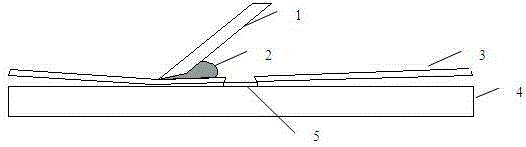

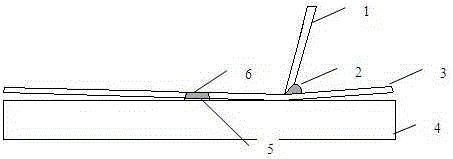

[0021] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

[0022] The invention discloses an electroformed nickel-iron alloy stencil for printing with high iron content, the stencil surface has an opening pattern area meeting the printing requirements; the nickel-iron alloy contains nickel Ni and iron Fe element; the mass percentage of each element is : Ni: 38-44%, Fe: 56-62%.

[0023] The metal stencil of the invention is applied to the production of high-precision circuit boards, and the metal stencil has certain magnetism, hardness and brightness. This kind of printing stencil adopts the ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| evenness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com