Method for preparing direct liquid fuel cell membrane electrode

A technology of liquid fuel cells and membrane electrodes, which is applied to fuel cell components and other directions, and can solve the problems of severe catalyst ion coating and low catalyst utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a method for preparing a membrane electrode of a direct liquid liquid fuel cell, comprising: mixing Nafion solution, alcohol solvent, water and a catalyst, then spraying it on the transfer film to form a catalytic layer, and then transferring it to the Nafion film On, obtain membrane electrode; The volume V of described Nafion solution Nafion Satisfy V Nafion =ρ 1 *m 载量 *S / (ρ 2 *ω*ρ 3 *a); where, ρ 1 is the density of pure Nafion, ρ 2 is the density of Nafion solution, ρ 3 is the density of the catalyst, m 载量 is the loading capacity of the catalyst per unit area of the membrane electrode, S is the total area of the membrane electrode, ω is the mass fraction of the Nafion solution, and a is a natural number ranging from 0.5 to 1.

[0040] The present invention has no special limitation on the sources of all raw materials, which can be commercially available. Wherein, the Nafion solution is a Nafion solution well known to those skilled ...

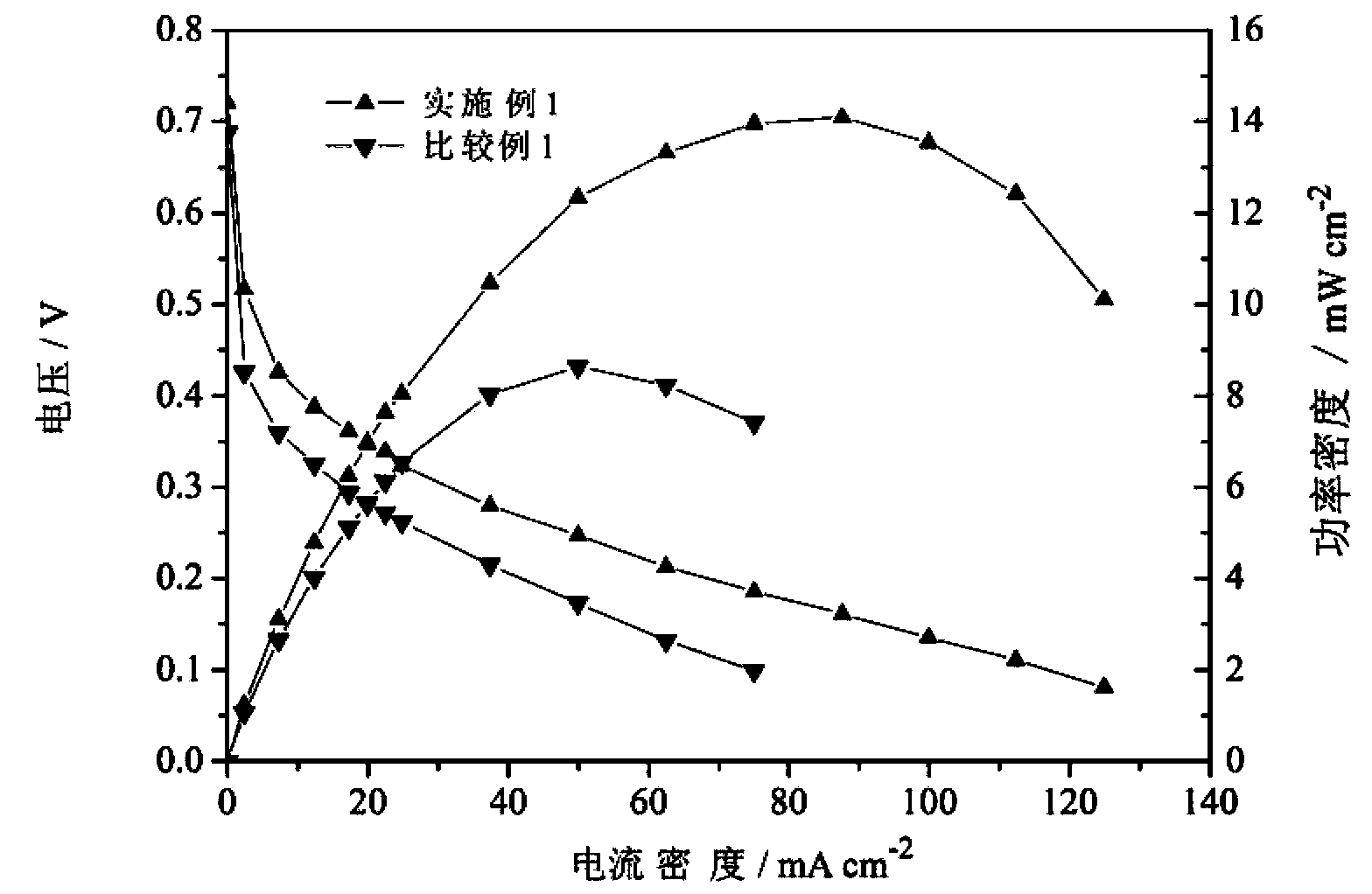

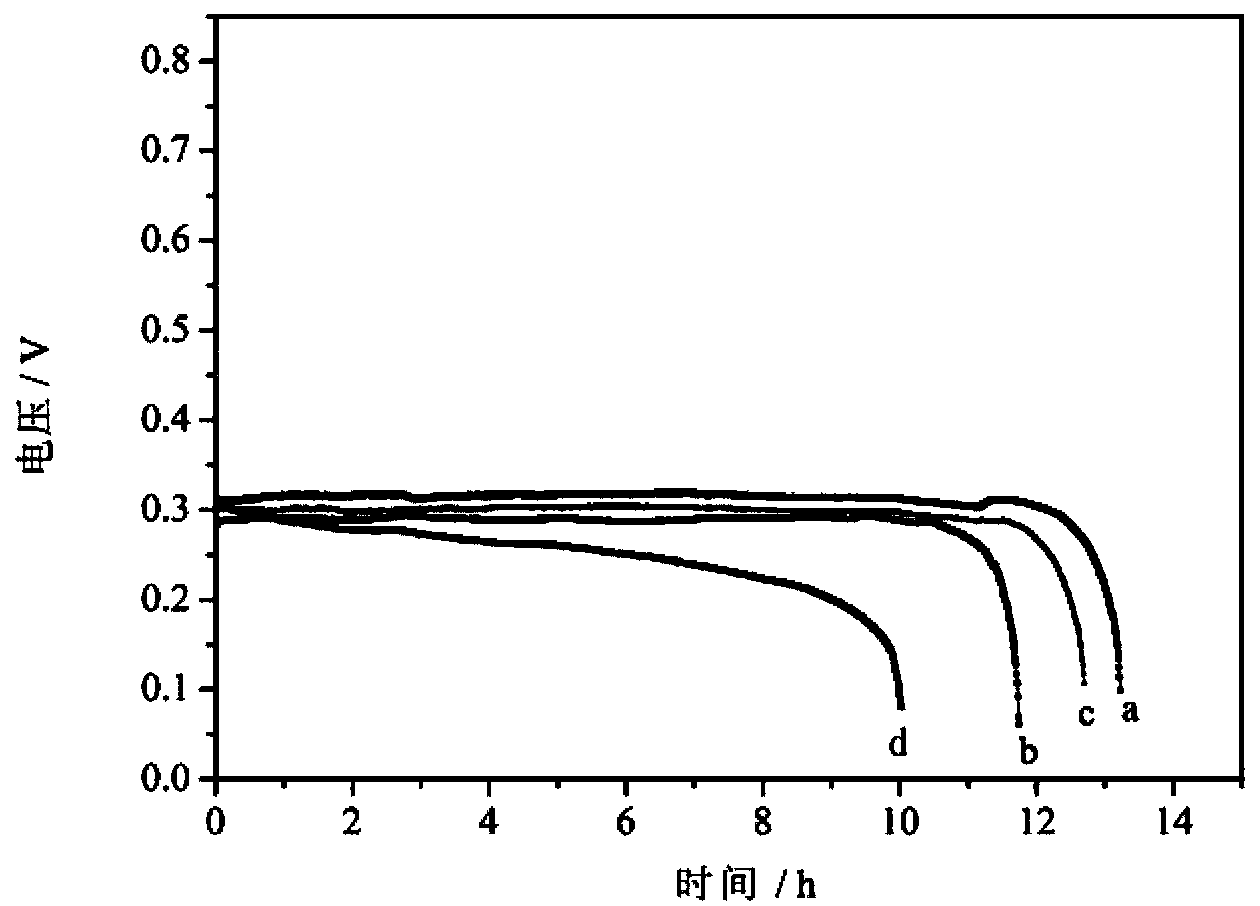

Embodiment 1

[0055] 1.1 The loading of the anode and cathode catalysts are both set to 5mg / cm 2 , the anode catalyst is PtRu (1:1) black catalyst, the microscopic particle density is 16.9g / cm 3 , the cathode catalyst is a Pt black catalyst, and the microscopic particle density is 21.45g / cm 3 ; The volume ratio of PtRu (1:1) black catalyst microscopic particles to microscopic Nafion particles is 1:1.5, that is (5*10 -3 / 16.9): (V 1 *0.875*5% / 1.4S)=1:1.5, where V 1 is the volume of Nafion solution for anode, S is the electrode area to be sprayed, the mass fraction of commonly used Nafion solution is 5%, and the density is 0.875g / cm 3 , the density of pure Nafion is 1.4g / cm 3 , the volume of Nafion solution required by the anode can be calculated according to the electrode area; the volume ratio of Pt black catalyst microscopic particles to microscopic Nafion particles is 1:1.5, that is (5*10 -3 / 21.45): (V 2 *0.875*5% / 1.4S)=1:1.5, the volume V of Nafion solution required by the cathode...

Embodiment 2

[0065] 2.1 The loading of anode and cathode catalysts are both set to 5mg / cm 2 , the anode catalyst is PtRu (1:1) black catalyst, the microscopic particle density is 16.9g / cm 3 , the cathode catalyst is a Pt black catalyst, and the microscopic particle density is 21.45g / cm 3 ; The volume ratio of PtRu (1:1) black catalyst microscopic particles to microscopic Nafion particles is 1:1, that is (5*10 -3 / 16.9): (V 1 *0.875*5% / 1.4S)=1:1, where V 1 is the volume of Nafion solution for anode, S is the electrode area to be sprayed, the mass fraction of commonly used Nafion solution is 5%, and the density is 0.875g / cm 3 , the density of pure Nafion is 1.4g / cm 3 , the volume of Nafion solution required by the anode can be calculated according to the electrode area; the volume ratio of Pt black catalyst microscopic particles to microscopic Nafion particles is 1:1, that is (5*10 -3 / 21.45): (V 2 *0.875*5% / 1.4S)=1:1, the volume V of Nafion solution required by the cathode can be calc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com