High-temperature sheet-type tantalum capacitor and manufacturing method thereof

A technology of tantalum capacitors and manufacturing methods, which is applied in the direction of capacitors, electrolytic capacitors, capacitor parts, etc., can solve problems such as not being able to withstand high temperature working environments, and achieve the effects of small size, good high temperature resistance, and excellent and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

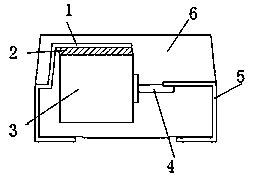

[0023] figure 1 and figure 2 A schematic diagram of the basic structure of the present invention is given. It can be seen from the accompanying drawings that the present invention is a chip-type solid electrolyte tantalum capacitor, which is basically the same in structure as the traditional chip-type solid electrolyte tantalum capacitor. The tantalum powder particles are designed to be pressed into shape, vacuum sintered to obtain the anode tantalum core 3, and then the tantalum pentoxide dielectric film is formed electrochemically, and then manganese dioxide is coated on it as the cathode, and finally the core block is assembled, and the epoxy resin 6 Molded plastic seals out the product. However, because it is a high-temperature product, a new manufacturing process has been adopted, as follows:

[0024] A. Anode design: choose tantalum metal powder with uniform particle size and large particle size, calculate the weight of tantalum powder according to the formation vol...

Embodiment 2

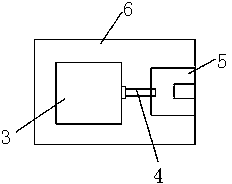

[0029] figure 1 and image 3A schematic diagram of a double-core structure of the present invention is given. The high-temperature chip tantalum capacitor includes a negative pole support plate 1, an adhesive silver paste 2, an anode tantalum core 3, a tantalum wire 4, a positive pole lead frame 5 and a high-temperature packaged Epoxy resin 6 on the outer layer of the chip tantalum capacitor, the negative plate 1 is connected to the anode tantalum core 3 by bonding silver paste 2, and the high temperature chip tantalum capacitor adopts a double-core structure, including two anode tantalum cores 3 and two tantalum wires 4 respectively connected to the two anode tantalum cores 3 , the two anode tantalum cores 3 are bonded together with silver paste 2 , and the two tantalum wires 4 are spot-welded on the positive lead frame 5 side by side.

[0030] The working principle and production method of the second embodiment are the same as those of the first embodiment, except that the ...

Embodiment 3

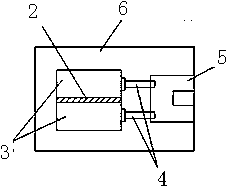

[0032] figure 1 and Figure 4 A schematic diagram of another multi-core structure of the present invention is given. The high-temperature chip tantalum capacitor includes a negative plate 1, an adhesive silver paste 2, an anode tantalum core 3, a tantalum wire 4, a positive lead frame 5 and a packaged at high temperature. Epoxy resin 6 on the outer layer of the chip tantalum capacitor, the negative plate 1 is connected to the anode tantalum core 3 by bonding the silver paste 2, and the high temperature chip tantalum capacitor adopts a multi-core structure, including three (also can It is more than three) anode tantalum cores 3 and three (or more than three) tantalum wires 4 respectively connected to the anode tantalum cores 3, the anode tantalum cores 3 are all connected together by bonding silver paste 2, and the tantalum wires 4 are all Parallel spot welding on the positive electrode lead frame 5 .

[0033] The working principle and production method of the third embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com