Field calibration method of on-wafer load traction measurement system

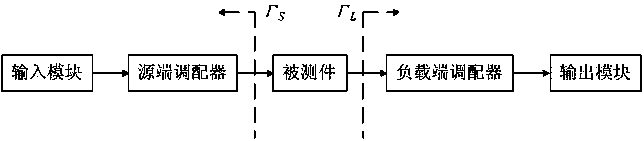

A technology of load-pull and measurement system, applied in the field of large-signal parameter performance, which can solve the problems of lack of effective measurement measures for overall performance indicators, large differences in load-pull parameter measurement results, inconsistent curves of test output power, gain, and efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be explained and described in more detail below in combination with specific embodiments.

[0035]A method for on-site calibration of an on-chip load pulling measurement system, specifically comprising the following steps:

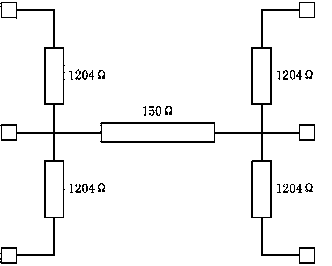

[0036] In the first step, a series of mismatch attenuation monoliths with different reflection coefficients are developed as transfer standard parts, and the reflection coefficient coverage range of the transfer standard parts is: 0.1-0.8.

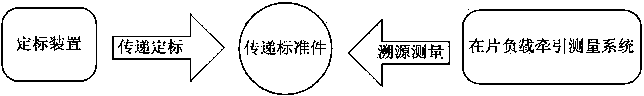

[0037] The present invention calibrates the developed transmission standard parts by building a calibration device, unifies the value of the on-chip load traction system, and provides a practical way to trace the source of the value of the on-chip load traction system, so the development and calibration of the transmission standard parts Work is an important link to realize the traceability of quantity and value.

[0038] In order to ensure a stable, repeatable gain characteristic tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com