Tin oxide-zinc oxide composite hollow microsphere gas sensor device and preparation method

A gas sensor, hollow microsphere technology, applied in the direction of material resistance, can solve the problems of poor gas selectivity and short response time, and achieve the effects of stable performance, simple production and improved response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

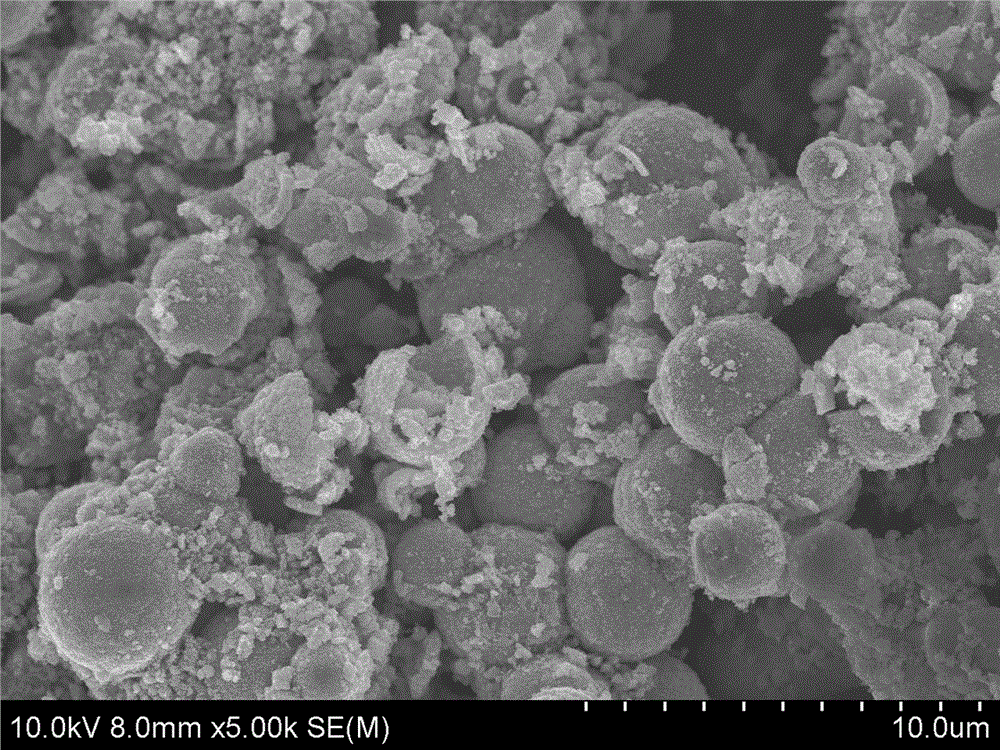

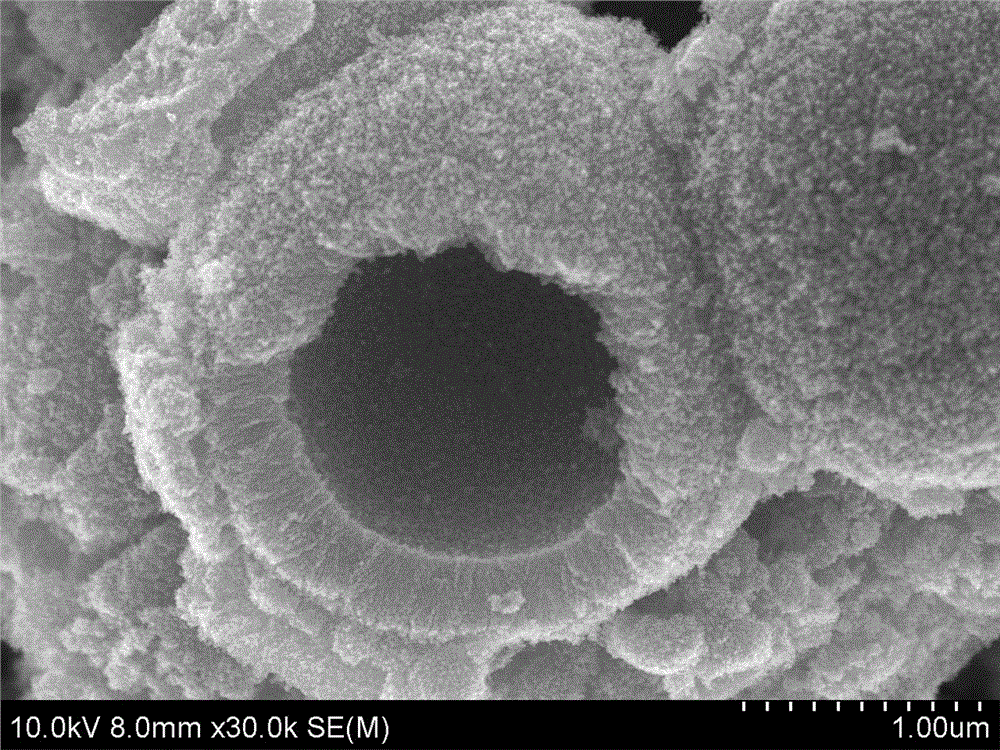

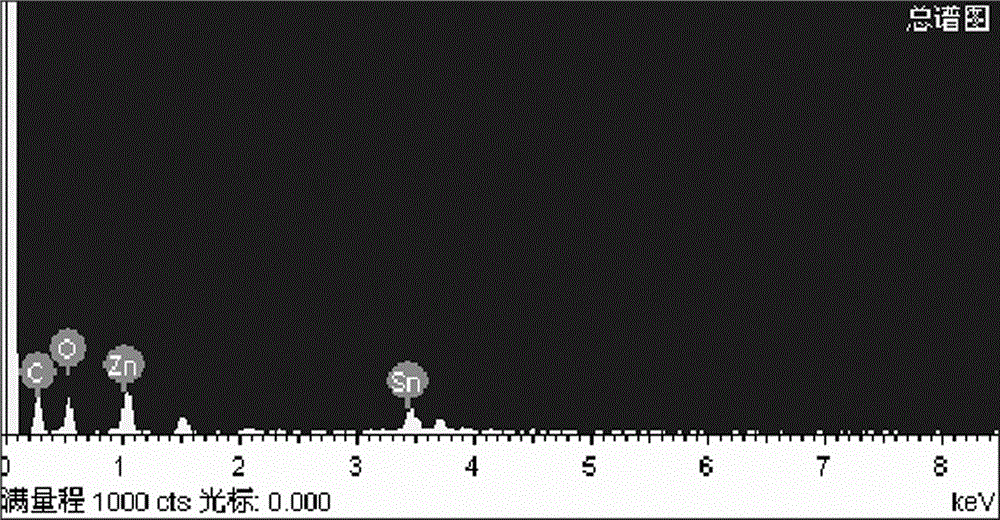

[0027] Example 1: Weigh 2g of block polymer P123, dissolve it in 25ml of absolute ethanol; add 0.43g of zinc acetate and 0.8ml of diethanolamine, and stir at room temperature for 3 hours to obtain a zinc precursor solution; weigh 0.12 g of stannous chloride was placed in the zinc precursor solution and stirred for 1 hour; the tin-zinc precursor solution was placed in a reaction kettle and reacted at 180°C for 24 hours; centrifuged and washed 3 times with alcohol and water respectively to obtain the oxidation Tin-zinc oxide composite hollow microspheres; dissolve the microspheres in absolute ethanol to obtain a paste; clean the alumina ceramic tube with deionized water, acetone, and chloroform, dry it, and put tin oxide-zinc oxide composite hollow microspheres The paste is uniformly coated on the surface of the ceramic tube, electrodes are welded and packaged to obtain a gas sensor. The diameter of the microspheres is between 2.5 and 3 microns, and the resistance response rate ...

Embodiment 2

[0028] Embodiment 2: Take the block polymer polystyrene-polyoxyethylene of 2.5g, be dissolved in the dehydrated alcohol of 30ml; Add the diethanolamine of the zinc acetate of 0.6g and 0.8ml, stir at room temperature for 3 hours to obtain zinc Precursor solution; weigh 0.15g of stannous chloride and place it in the zinc precursor solution, stir for 1 hour; place the tin-zinc precursor solution in a reaction kettle, and react at 180°C for 24 hours; use alcohol and water respectively Centrifuge and wash 3 times to obtain tin oxide-zinc oxide composite hollow microspheres; dissolve the microspheres in absolute ethanol to obtain a paste; clean the alumina ceramic tube with deionized water, acetone, and chloroform, dry it, and dissolve the tin oxide - The zinc oxide composite hollow microsphere paste is evenly coated on the surface of the ceramic tube, the electrodes are welded and packaged to obtain a gas sensor. The diameter distribution of tin oxide-zinc oxide composite hollow mi...

Embodiment 3

[0029] Example 3: Weigh 2g of block polymer P123, dissolve it in 30ml of deionized water; add 0.1g of zinc acetate and 1ml of diethanolamine, and stir at room temperature for 3 hours to obtain a zinc precursor solution; weigh 0.45g of Put stannous chloride in the zinc precursor solution and stir for 1 hour; put the tin-zinc precursor solution in a reaction kettle and react at 180°C for 24 hours; wash with alcohol and water for 3 times, respectively, to obtain tin oxide- Zinc oxide composite hollow microspheres; dissolve the microspheres in absolute ethanol to obtain a paste; clean the alumina ceramic tube with deionized water, acetone, and chloroform, dry it, and make the tin oxide-zinc oxide composite hollow microspheres into a paste The substance is evenly coated on the surface of the ceramic tube, and the electrodes are welded and packaged to obtain a gas sensor. The size distribution of the microspheres obtained by changing the ratio of tin and zinc is in the range of 2 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com