Test method for testing bending fatigue life of film

A bending fatigue and test method technology, which is applied in the direction of applying repetitive force/pulsation force to test the strength of materials, etc., can solve the problems of taking a lot of time and cost, not applicable to insulating films, not applicable to bending fatigue behavior of film materials, etc., to save Time and cost, quick and easy to obtain, widely applicable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

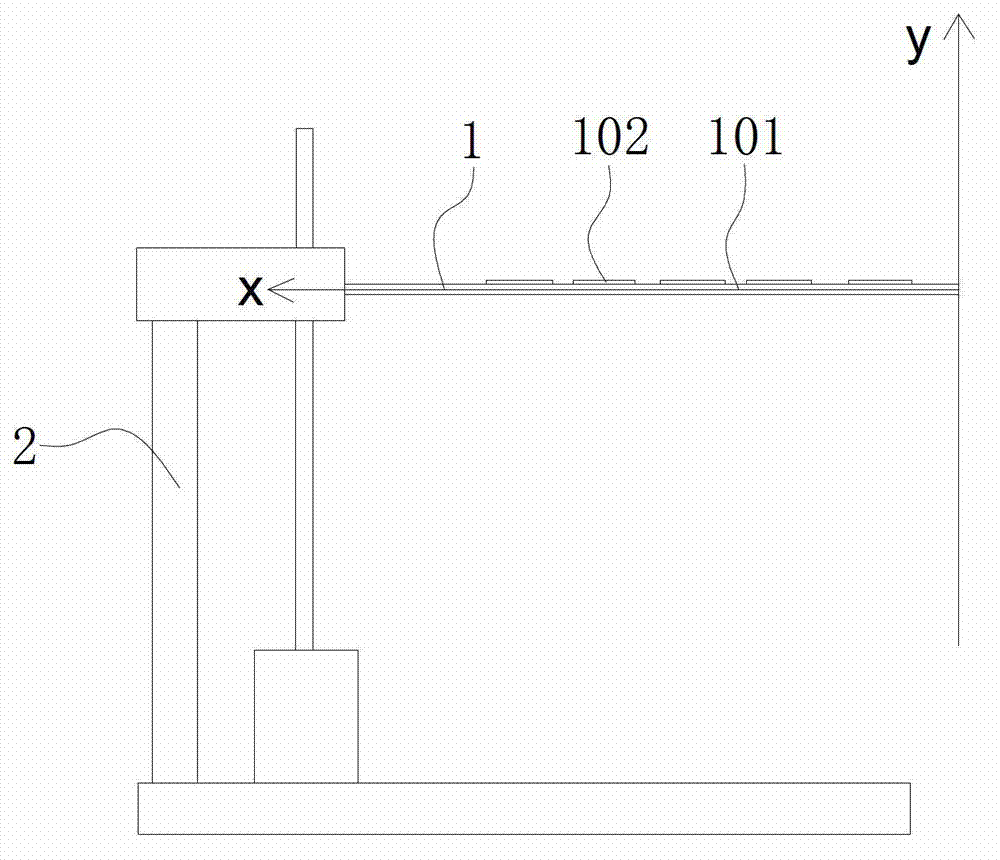

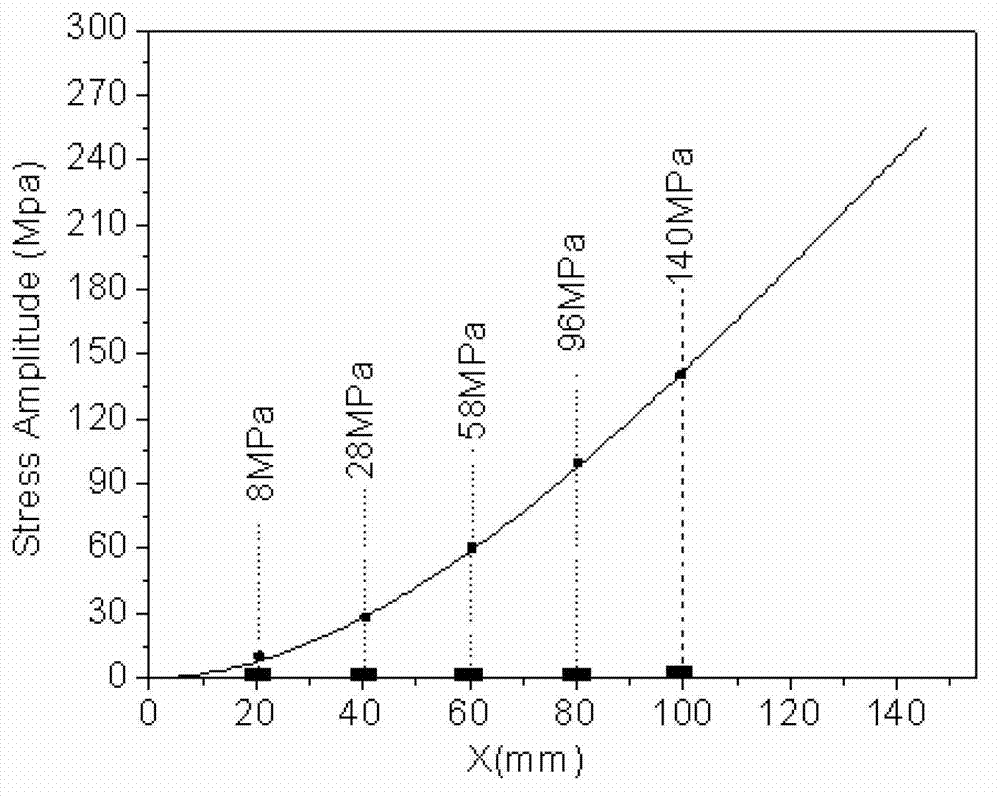

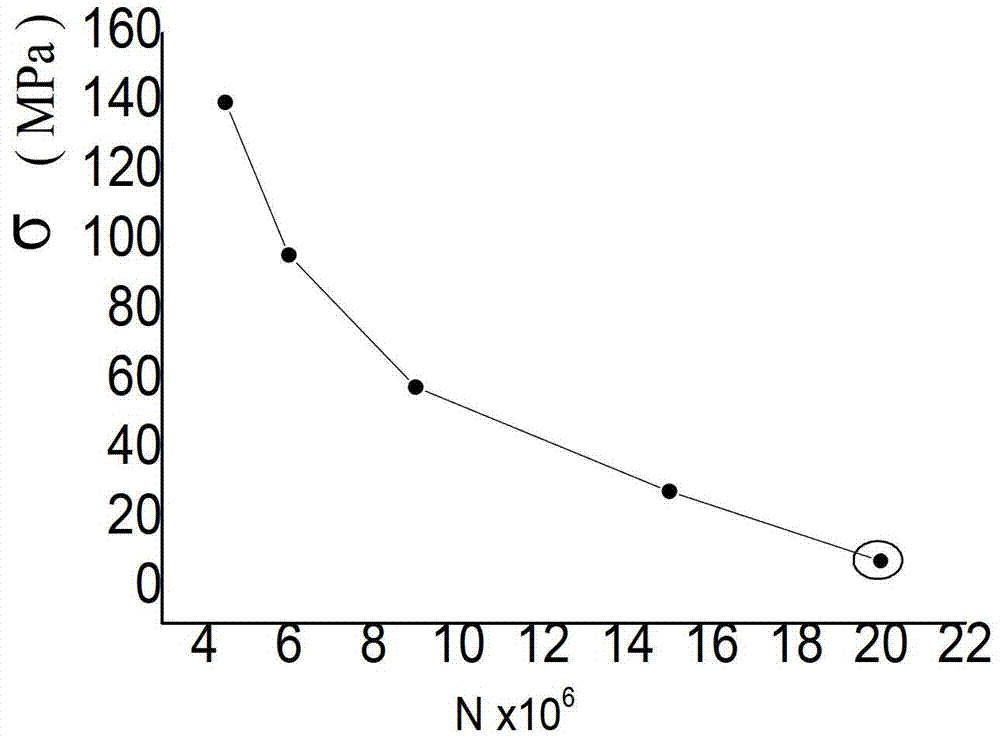

[0042] Using cobalt alloy as the substrate 101, the bending fatigue life of the titania film 102 deposited on the surface of the substrate 101 under different stress amplitudes was tested. Below this sample sample 1 is taken as an example to illustrate the principle and specific operation steps of the inventive method:

[0043] A. Process the cobalt-based alloy into a flake shape with a length l of 150 mm, a width b of 7 mm, and a thickness h of 0.7 mm as the substrate 101, and then deposit five pieces of 7×7 mm on the surface of the substrate 101 by magnetron sputtering at equal intervals 2 The rutile-type titanium dioxide film 102 is used as a sample 1, the thickness w of the film 102 is 80nm, and the elastic modulus E=24000Mpa of the cobalt-based alloy;

[0044] B. Using the cantilever beam vibration equipment 2 to make the sample 1 perform cantilever beam bending vibration, the sample 1 is subjected to cantilever beam bending vibration so that the film 102 deposited on its...

Embodiment 2

[0050] The bending fatigue life of TiN and DLC subjected to the same stress amplitude on the surface of the stainless steel substrate 101 was tested. The process of this embodiment is basically the same as that of Embodiment 1, the difference is that TiN and DLC are respectively deposited on the front and back sides of the same position of the cantilever beam sample 1, and the fatigue life of two different films 102 under the same stress range can be tested at the same time , thus saving test time and cost. The experimental results show that under the stress amplitude of 140Mpa, the fatigue life of 1 micron TiN is 3.5 million times, and the fatigue life of 0.5 micron DLC is 3 million times.

Embodiment 3~15

[0052] Embodiments 3 to 15 have the same operating steps as in Example 1, except that the base material and size of the sample are different; the type of film to be detected and the thickness of the film are different; the frequency of the sample vibration is different; the time of each vibration is different; The spacing of sampling points is different when the amplitude is distributed. The specific parameters above are shown in the table below:

[0053]

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com