Brake pad capable of detecting and preventing abrasion

A technology of brake pads and friction blocks, applied in the field of brake pads that can detect and prevent wear, can solve problems such as rising costs, waste, and failure to find the cause of excessive wear in time, and achieve the effect of preventing excessive wear and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

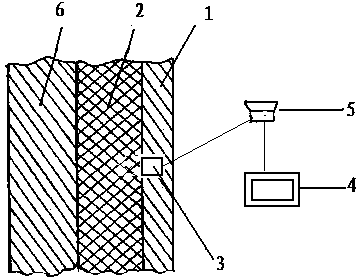

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

[0013] Such as figure 1 As shown, a brake pad capable of detecting and preventing wear includes a steel plate 1 and a friction block 2. The end of the steel plate 1 close to the friction block 2 is provided with a thickness sensor 3 that can detect the thickness of the friction block 2. The thickness sensor 3 is connected to the friction block 2. The monitor 4 installed in the car is connected.

[0014] The thickness sensor 3 is also connected with an alarm 5 .

[0015] The material of the friction block 2 is an asbestos-free organic material added with glass fibers. The material has good wear resistance, can maintain a good braking effect no matter in high temperature or low temperature, reduces wear and tear, has low noise, and can prolong the service life of the brake disc 6 .

[0016] Before use, the user needs to set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com