Buckling stainless steel protective sleeve, multi-section spliced stainless steel protective sleeve and manufacturing method

A technology of sheath pipe and stainless steel, which is applied in the direction of bridge parts, bridges, buildings, etc., to achieve the effect of simple and convenient installation process, reduced material consumption, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

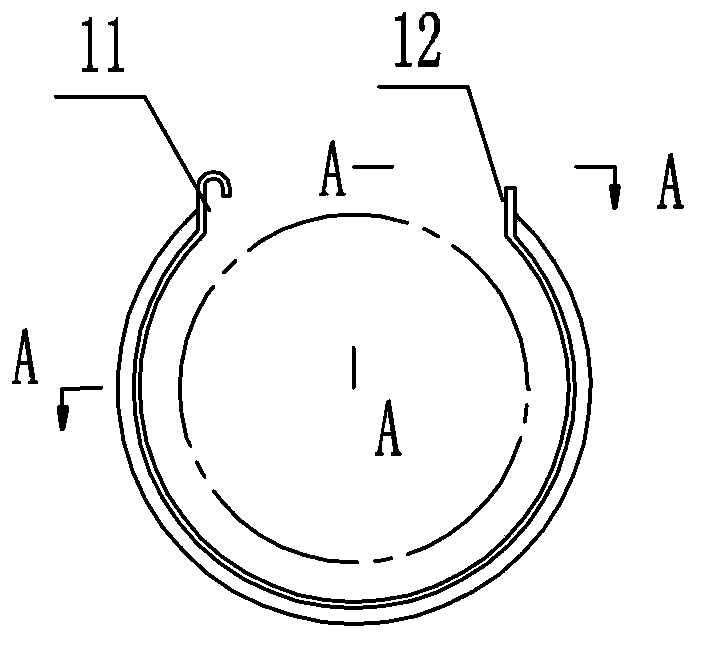

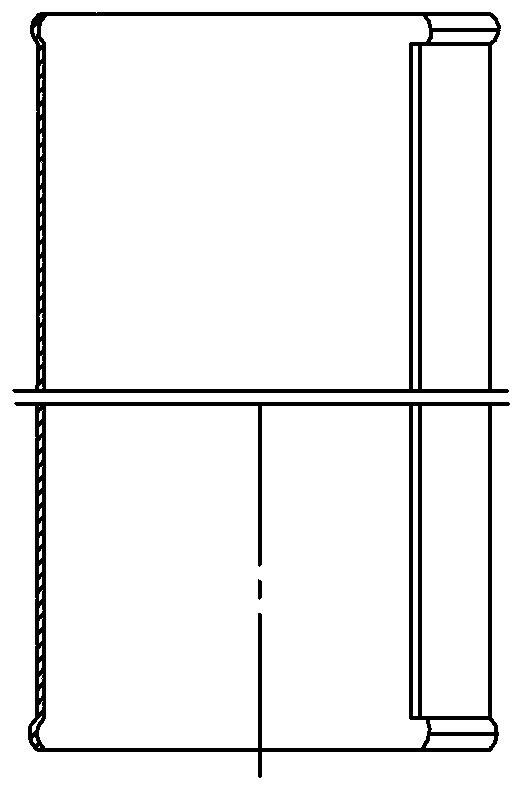

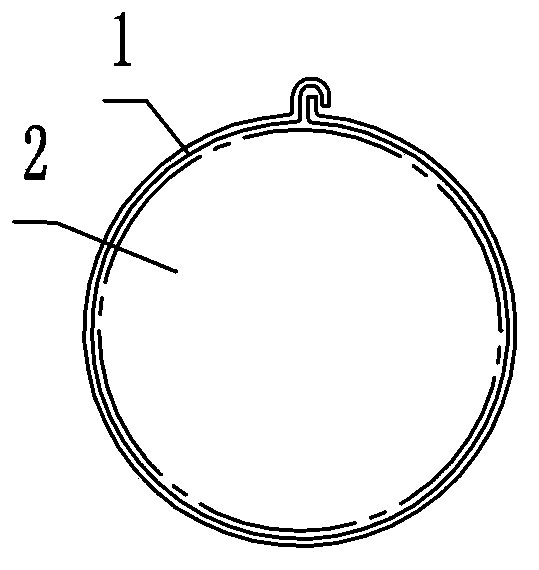

[0060] A snap-fit stainless steel sheath tube such as Figure 1-1~Figure 1-2 As shown, the snap-fit stainless steel sheath tube is an arc-shaped sheath tube with an approximately circular cross-section and two connecting ends before it is buckled, forming the edge of one long side of the arc-shaped sheath tube- That is, one connection end of the arc-shaped sheath tube is an inverted U-shaped structure connection end 11, which constitutes the edge of the other long side of the arc-shaped sheath tube—that is, the other connection end of the arc-shaped sheath tube It is the connecting end 12 of I-shaped structure. In the buckled state, the rectangular plate constituting the arc-shaped sheath tube 1 is buckled by the inverted U-shaped structure and I-shaped structure of the two long sides and edges, and becomes an integral body with a connecting end. round (see Figure 2-1 ), after being flattened, it becomes a full circular sheath tube and tightly wraps the cable body 2 (see...

Embodiment 2

[0062] A multi-section splicing and snap-fit stainless steel sheath tube, comprising more than two sections of stainless steel sheath tube, each section of stainless steel sheath tube is the buckle-fit stainless steel sheath tube described in Embodiment 1; two adjacent sections of stainless steel sheath The pipes are spliced into one body through the connection method of lap joint or bayonet structure connection.

[0063] For the multi-segment spliced snap-fit stainless steel sheath pipe 3 spliced by lap joints, such as Figure 3-1 As shown, the two ends of each section of stainless steel sheath pipe are provided with arc-shaped, V-shaped or trapezoidal transition connection protrusions 30, and the upper and lower adjacent stainless steel sheath pipes 31, 32 are overlapped by rounded corners (see Figure 3-2 ), V-lap (see Figure 3-3 ) or trapezoidal lap (see Figure 3-4 ) are spliced into one.

[0064] For the multi-section splicing snap-fit stainless steel ...

Embodiment 3

[0067] A method for manufacturing and installing a multi-segment spliced stainless steel sheath tube, the multi-segment spliced stainless steel sheath tube is the multi-segment spliced snap-fit stainless steel sheath tube described in Embodiment 2, including more than two segments of stainless steel sheath tubes, each segment of stainless steel sheath tube The sleeve is the snap-fit stainless steel sheath tube described in Embodiment 1; the upper and lower adjacent stainless steel sheath tubes are spliced into one body through the connection mode of lap joint or the connection mode of bayonet structure connection.

[0068] (1) The manufacturing method of each buckle-fit stainless steel sheath pipe is as follows:

[0069] A. Making arc-shaped snap-fit stainless steel sheath tube:

[0070] 1. Blanking: making the rectangular plate Ⅰ that constitutes the arc-shaped sheath pipe 1:

[0071] Design the length L of each snap-fit stainless steel sheath tube according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com