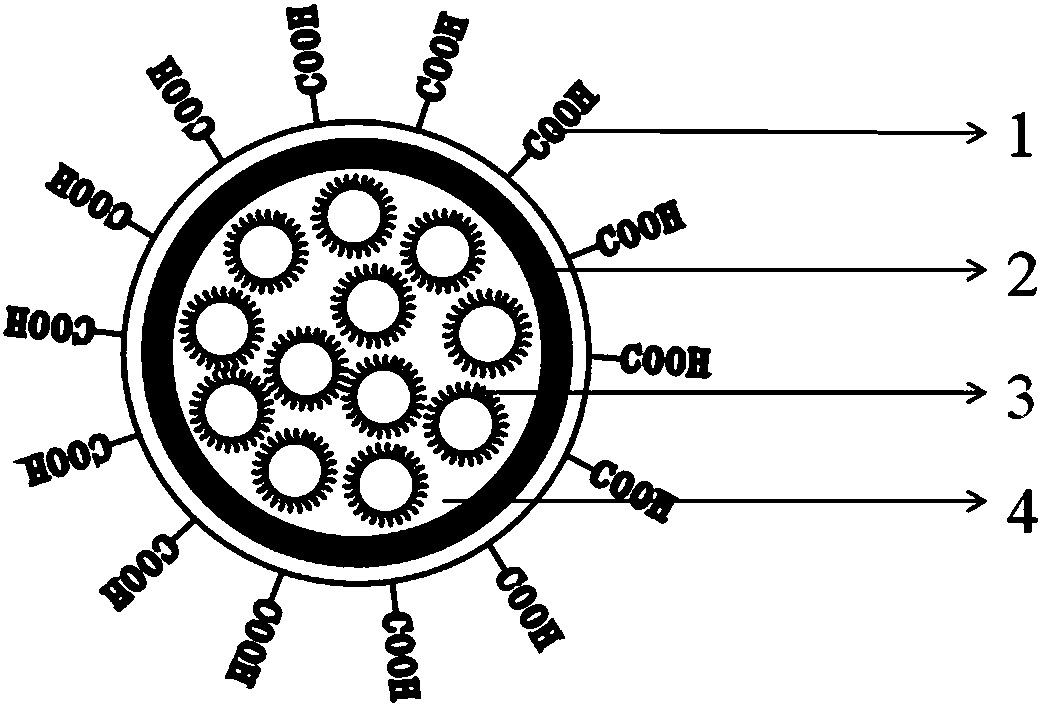

Water-soluble quantum dot fluorescent nanosphere and preparation method thereof

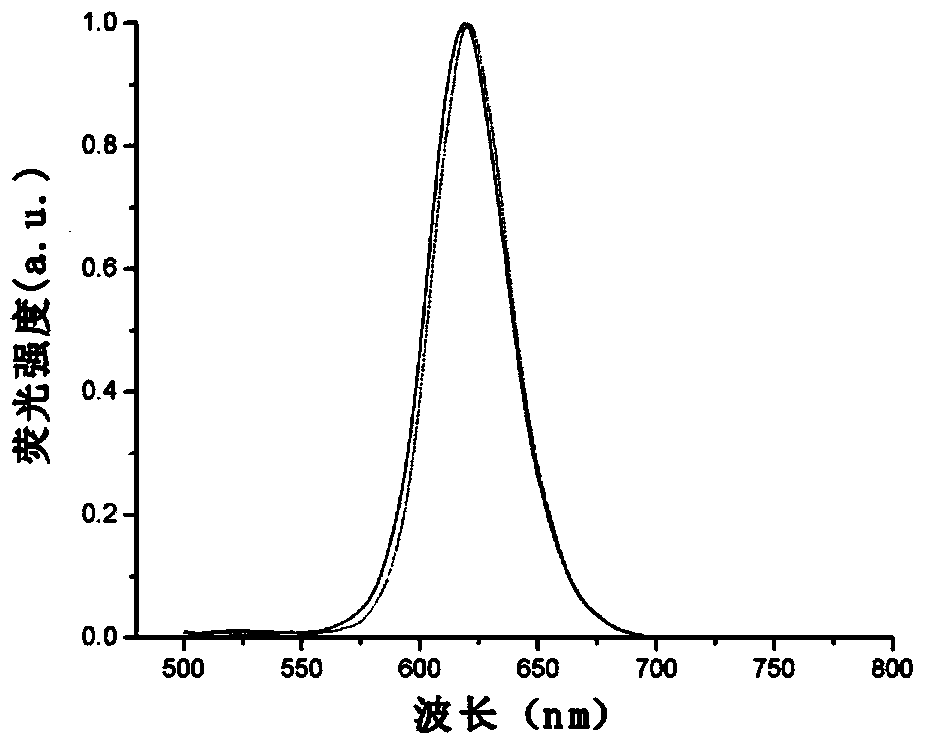

A fluorescent nanometer and quantum dot technology, applied in the field of detection, can solve the problems of easy fluorescence quenching, influence of detection results, and low fluorescence efficiency, and achieve the effects of good fluorescence and colloidal stability, easy operation, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0031] 1. Preparation process of amphiphilic polymer. The acrylamide polymer used is: polymethacrylic acid, the alkylamine used is: octylamine, and the coupling agent used is EDC. The molar ratio of raw materials is:

[0032] Polymethacrylic acid:octylamine=1:20

[0033] Octylamine: EDC=1:3

[0034] (1) Dissolve 1 g of polymethacrylic acid in 20 mL of DMSO, and stir at 35° C. for 12 to 24 hours.

[0035] (2) Add 26 uL of octylamine into the solution obtained in step (1), continue to stir for 4 to 6 hours, turn off the heating, and cool down to room temperature.

[0036] (3) Weigh 0.12g of EDC, dissolve it in 10mL of DMSO and add it to the mixture in step (2), and react for 12-16 hours. The obtained mixture was purified by dialysis with ethanol and water respectively, and then taken out and freeze-dried to obtain the amphiphilic polymer.

[0037] 2. The preparation process of water-soluble quantum dot fluorescent nanospheres. The quantum dots used are CdZnSe quantum dots,...

Embodiment example 2

[0044] 1. Preparation process of amphiphilic polymer. The acrylamide polymer used is: polymethacrylic acid; the alkylamine used is: octylamine; the coupling agent used is EDC. The molar ratio of raw materials is:

[0045] Polymethacrylic acid:octylamine=1:40

[0046] Octylamine: EDC=1:3

[0047] (1) Dissolve 1 g of polymethacrylic acid in 20 mL of DMSO, and stir at 35° C. for 12 to 24 hours.

[0048] (2) Add 51 uL of octylamine into the solution obtained in step (1), continue to stir for 4 to 6 hours, turn off the heating, and cool down to room temperature.

[0049] (3) Weigh 0.23g of EDC, dissolve it in 10mL of DMSO and add it to the mixture in step (2), and react for 12-16 hours. The obtained mixture was purified by dialysis with ethanol and water respectively, and then taken out and freeze-dried to obtain the amphiphilic polymer.

[0050] 2. The preparation process of water-soluble quantum dot fluorescent nanospheres. The quantum dots used are CdZnSe quantum dots, the...

Embodiment example 3

[0057] 1. Preparation process of amphiphilic polymer. The acrylamide polymer used is: poly(2-ethylacrylic acid); the alkylamine used is: dodecylamine; the coupling agent used is EDC. The molar ratio of raw materials is:

[0058] Poly(2-ethylacrylic acid): dodecylamine = 1:60

[0059] Octylamine: EDC=1:3

[0060] (1) Dissolve 1 g of poly(2-ethylacrylic acid) in 20 mL of DMSO, and stir at 35°C for 12 to 24 hours.

[0061] (2) Weigh 0.12 g of dodecylamine and add it to the solution obtained in step (1), continue to stir for 4 to 6 hours, turn off the heating, and cool down to room temperature.

[0062] (3) Weigh 0.35g of EDC, dissolve it in 10mL of DMSO and add it to the mixture in step (2), and carry out the reaction for 12-16 hours. The obtained mixture was purified by dialysis with ethanol and water respectively, and then taken out and freeze-dried to obtain the amphiphilic polymer.

[0063] 2. The preparation process of water-soluble quantum dot fluorescent nanospheres. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com