A kind of phenyl vinyl silicone resin for LED encapsulation and preparation method thereof

A phenylvinyl silicon, LED packaging technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of difficult to meet application requirements, poor impact resistance, large internal stress, etc., and achieve excellent thermal shock resistance. , good tensile strength, fast vulcanization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

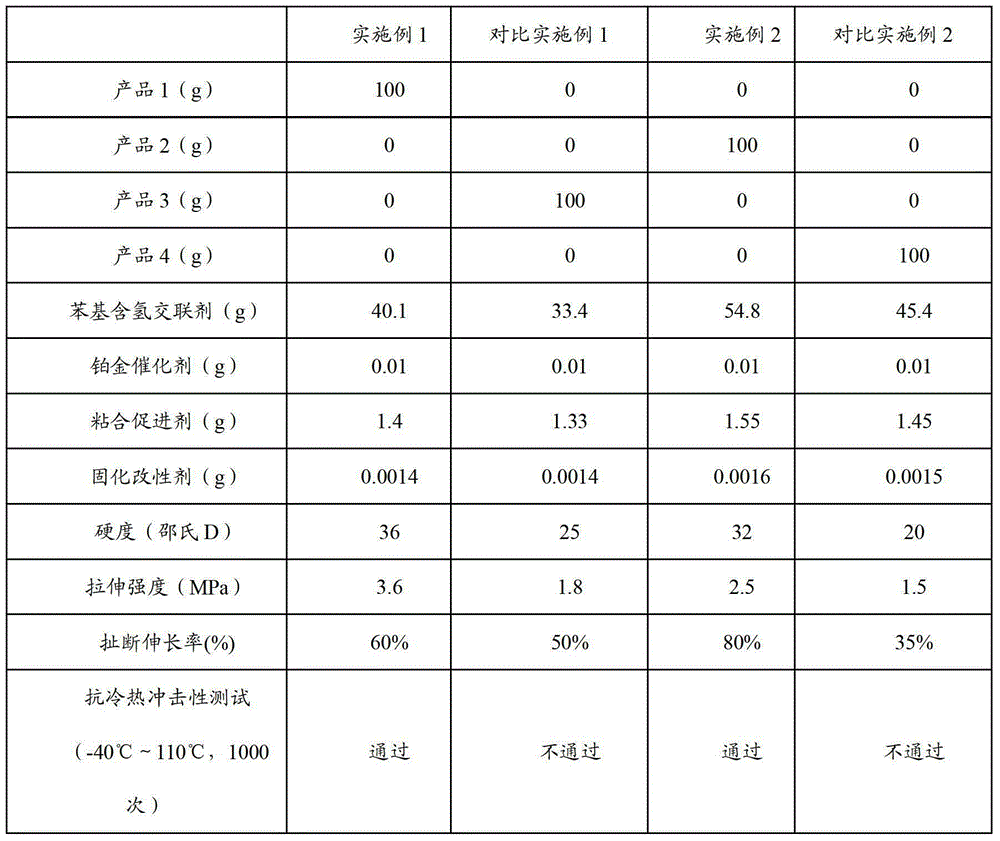

Examples

preparation example Construction

[0025] The present invention also provides a preparation method of the above-mentioned phenyl vinyl silicone resin for LED packaging, which comprises the following steps:

[0026] Mix 1-100 parts by mass of phenylalkoxysilane monomer, 10-50 parts of organic solvent and 20-40 parts of water, and add 0.1-10% of the mass of phenylalkoxysilane monomer dropwise acid catalyst, reacted at 0-30°C for 1-8 hours to obtain reaction solution A;

[0027] Add at least one of alkoxy-terminated polydimethylsiloxane, polymethylphenylsiloxane, and polydimethyldiphenylsiloxane to the reaction solution A, and continue the reaction for 3- After 10 hours, add vinyl capping agent and react for 1 to 3 hours to obtain reaction solution B;

[0028] The reaction solution B is allowed to stand for stratification, after removing the acid solution in the upper layer, adding alkali to adjust the pH value to neutral, and washing to obtain a mixture;

[0029]The mixture is heated to 110° C. to 130° C. under...

Embodiment 1

[0039] In a 2L three-necked flask equipped with 100g of toluene and 50g of water, add 198g of phenyltrimethoxysilane, 244.4g of diphenyldimethoxysilane, and 18.2g of methylphenyldimethoxysilane at 30°C Add 30 parts of hydrochloric acid with a mass fraction of 25% dropwise, stir well, and finish the dropwise addition within one hour, then continue to stir for 2 to 3 hours, then add 76.3g of CH 3 O(CH 3 ) 2 Si[(OSi(CH 3 ) 2 )] 18 OSi(CH 3 ) 2 OCH 3 Polydimethylsiloxane, and 20g toluene, reacted for 1 hour, raised the temperature to 80°C, added 111.6g of tetramethyldivinyldisiloxane, kept the temperature at 80°C, stopped the reaction after 10 hours, cooled to Separate layers at room temperature, add 5g of sodium hydroxide to neutralize, wash with water until neutral, decompress for 3 hours at 110°C, vacuum degree of 0.9MPa ~ 1.0MPa, remove low boiling point substances, and obtain colorless and transparent phenyl Vinyl silicone resin 392.3g, viscosity 8000mPa.s / 25℃, refrac...

Embodiment 2

[0041] In a 2L three-necked flask equipped with 100g toluene and 50g water, add 198g phenyltrimethoxysilane, 488.8g diphenyldimethoxysilane, 9.1g methylphenyldimethoxysilane, and then Add 30 parts of hydrochloric acid with a mass fraction of 25% dropwise, stir well, and finish the dropwise addition within one hour, then continue to stir for 2 to 3 hours, then add 43g of CH 3 O(CH 3 ) 2 Si[(OSi(CH 3 ) 2 )] 9 OSi(CH 3 ) 2 OCH 3 Polydimethylsiloxane and 20g of toluene, react for 1 hour, heat up to 80°C, add 223.2g of tetramethyldivinyldisiloxane, keep the temperature at 80°C, stop the reaction after 10 hours, cool to room temperature Then separate layers, add 5g of sodium hydroxide to neutralize, wash with water until neutral, depressurize for 3 hours at 110°C and vacuum degree of 0.9MPa~1.0MPa, remove low boiling point substances, and obtain colorless transparent phenylethylene Base silicone resin 392.3g, viscosity 3000mPa.s / 25℃, refractive index 1.5401 / 20℃, vinyl conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com