A positioning pin sleeve

A positioning sleeve and positioning pin technology, applied in the direction of overhead lines, etc., can solve the problems of difficult to meet the electrified railway, increase the load of the catenary, and easily generate electrical corrosion, so as to reduce the load of the catenary, solve the problem of electrical corrosion, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

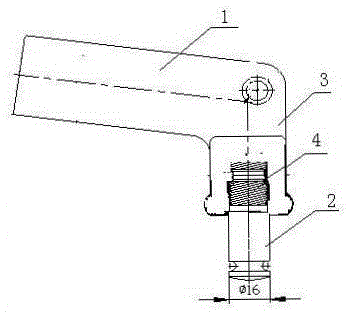

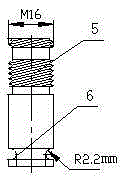

[0015] As shown in the figure, a positioning pin sleeve includes a positioning sleeve 1 and a pin 2, wherein the positioning sleeve 1 is made of an aluminum alloy material through a metal die forging forming process, and the pin 2 is manufactured by a copper alloy bar machining process. The positioning sleeve 1 is a cylindrical member, and the connecting portion 3 connecting the positioning sleeve 1 and the pin 2 is provided with a threaded hole; the connecting portion 3 is a cylindrical structure with a diameter of 30mm, and the connecting portion 3 is provided with a There is a threaded hole 4 with a diameter of 16 mm; the pin 2 is a cylindrical structure, the upper part is provided with a thread 5 to form a ring groove space, and the lower part is provided with a U-shaped groove 6 with a radius of 2.2 mm.

[0016] The positioning sleeve and the pin are made by forging and fixing process, using a cavity crimping die with a shape similar to the pin, forging and pressing on a 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com