Method for preparing iron-based superconducting wire

An iron-based superconducting and wire technology, which is applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve the problem of reducing the transmission performance of wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

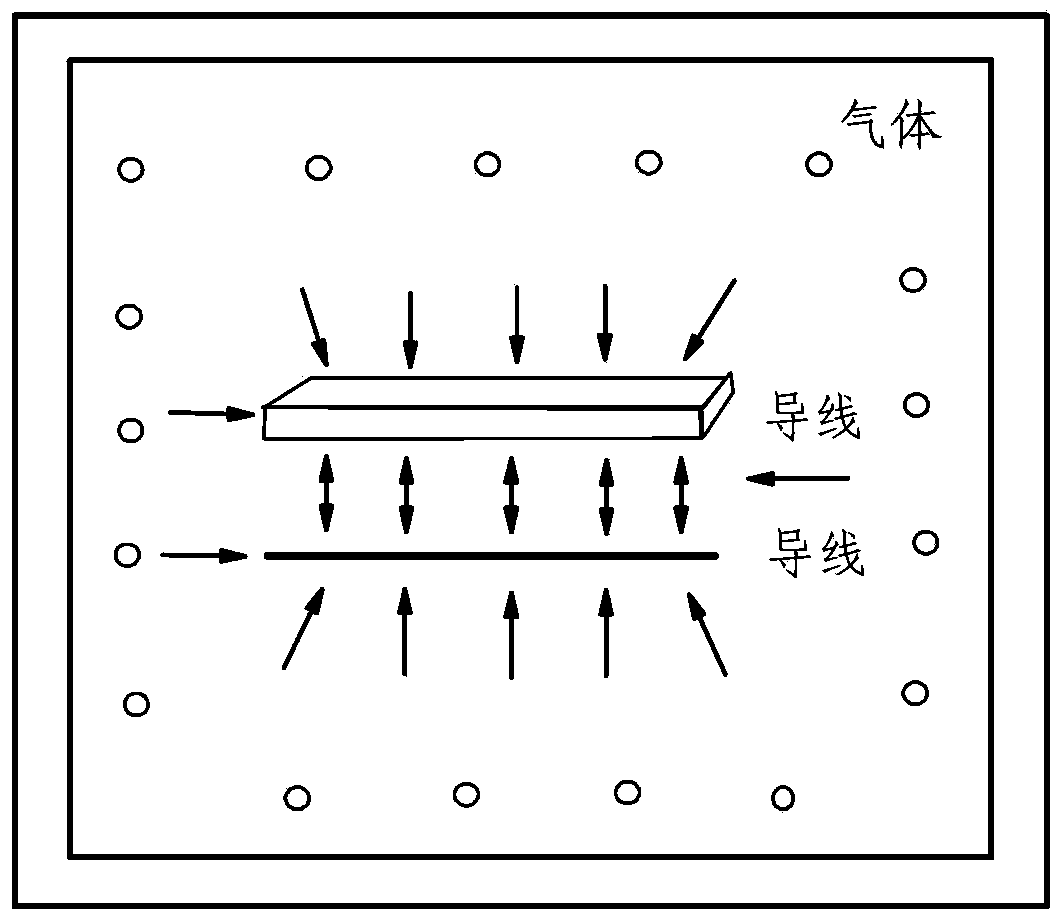

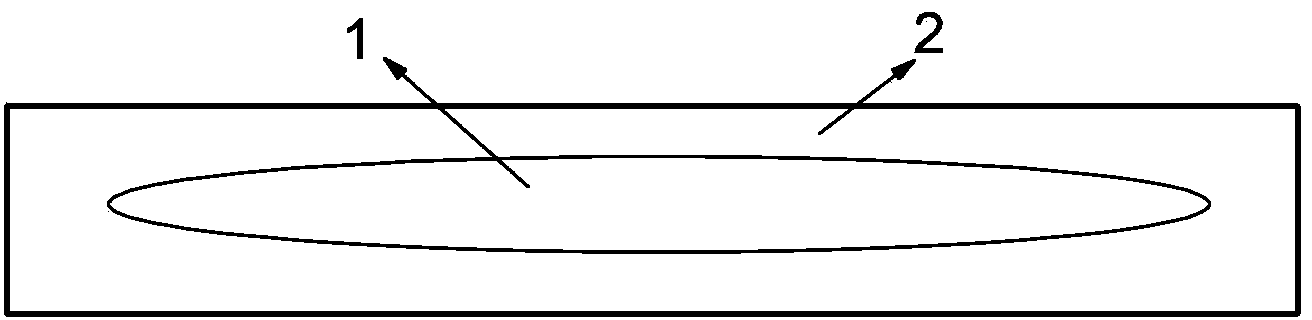

[0020] Put the powder of LaFeAsOF (La-1111) into the Nb tube, and the structure of the single-core iron-based strip after swaging, drawing and rolling is as follows Figure 3a As shown, after sealing the two ends of the above-mentioned strips separately, put them into high-temperature and high-pressure equipment, such as figure 1 shown. Pressurize to 10MPa at room temperature, then heat up to 500°C and keep warm for 20 hours, then cool down to room temperature, such as figure 2 shown. Take out the sample to make iron-based superconducting wire. During the high-pressure process, the pressure is always kept at 10MPa, and the high-pressure gas introduced into the high-pressure heat treatment process is argon.

Embodiment 2

[0022] Put the powder of LaFeAsOF (La-1111) into the Nb tube, and the structure of the single-core iron-based wire after swaging and drawing is as follows: Figure 3b As shown, after the two ends of the above-mentioned wires are sealed, they are put into high temperature and high pressure equipment. Pressurize to 10MPa at room temperature, then heat up to 500°C and keep warm for 20 hours, then cool down to room temperature, such as figure 2 shown. Take out the sample to make iron-based superconducting wire. During the high-pressure process, the total pressure is always maintained at 110MPa, and the high-pressure gas is argon.

Embodiment 3

[0024] Put the powder of LaFeAsOF (La-1111) into the Nb tube, and obtain a 7-core wire rod after swaging and drawing. After sealing the two ends of the wire rod, put it into a high-temperature and high-pressure equipment. First pressurize to 200MPa at room temperature, then raise the temperature to 600°C and keep it warm for 20 hours, then cool down to room temperature, take out the sample, and then make the iron-based superconducting wire. During the high-pressure process, the total pressure is always maintained at 200MPa, and the high-pressure gas is argon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com