Vertical pres-stressed anchor rod gravity-type composite retaining wall and method for designing and constructing retaining wall

A technology of vertical prestressing and composite retaining walls, which is applied to artificial islands, sheet pile walls, water conservancy projects, etc., can solve problems such as the stability of disturbed slopes, large space requirements for retaining walls, and difficulty in guaranteeing the design service life. Good effect of preventing slope disasters, reducing gravity and occupying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

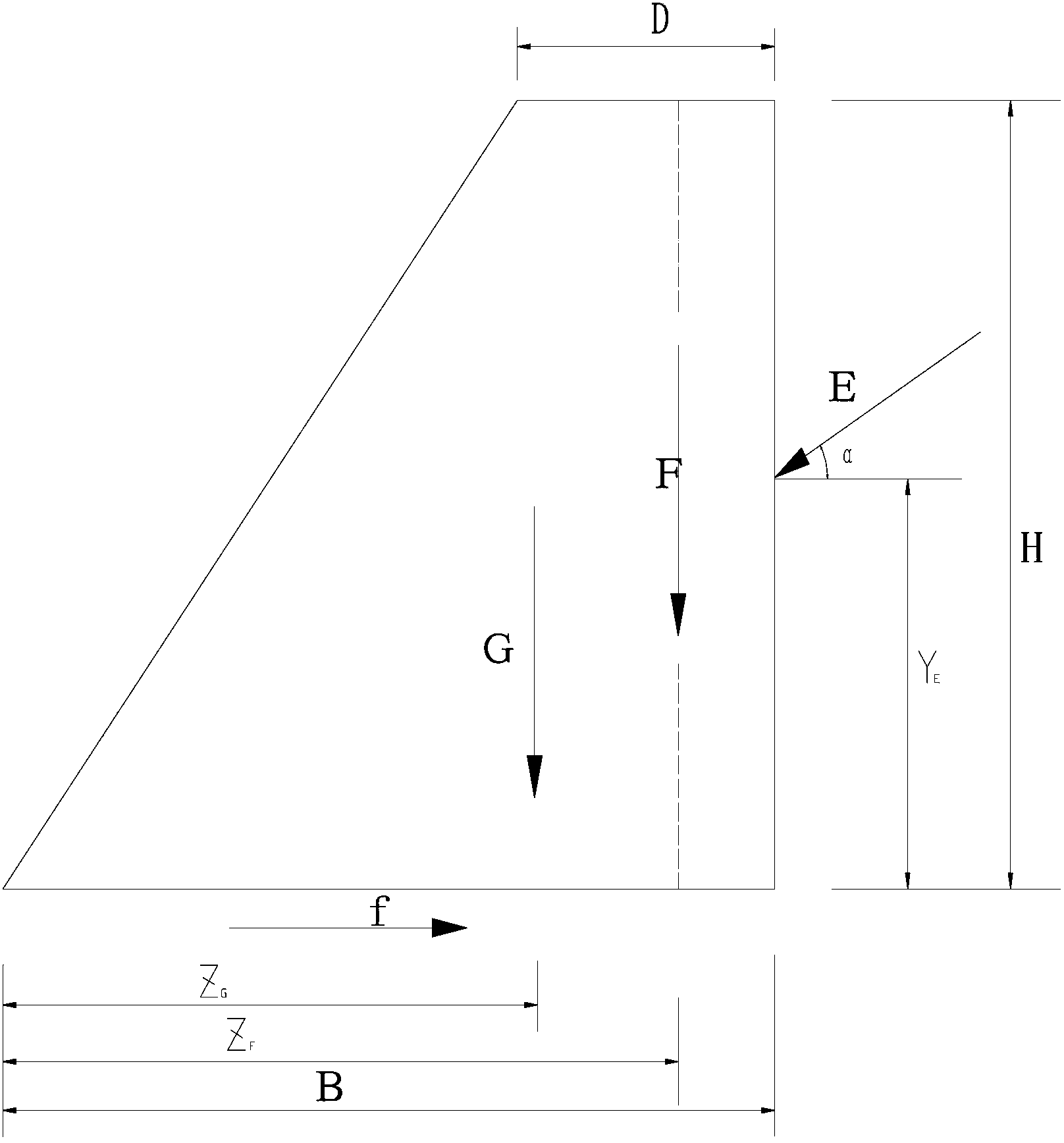

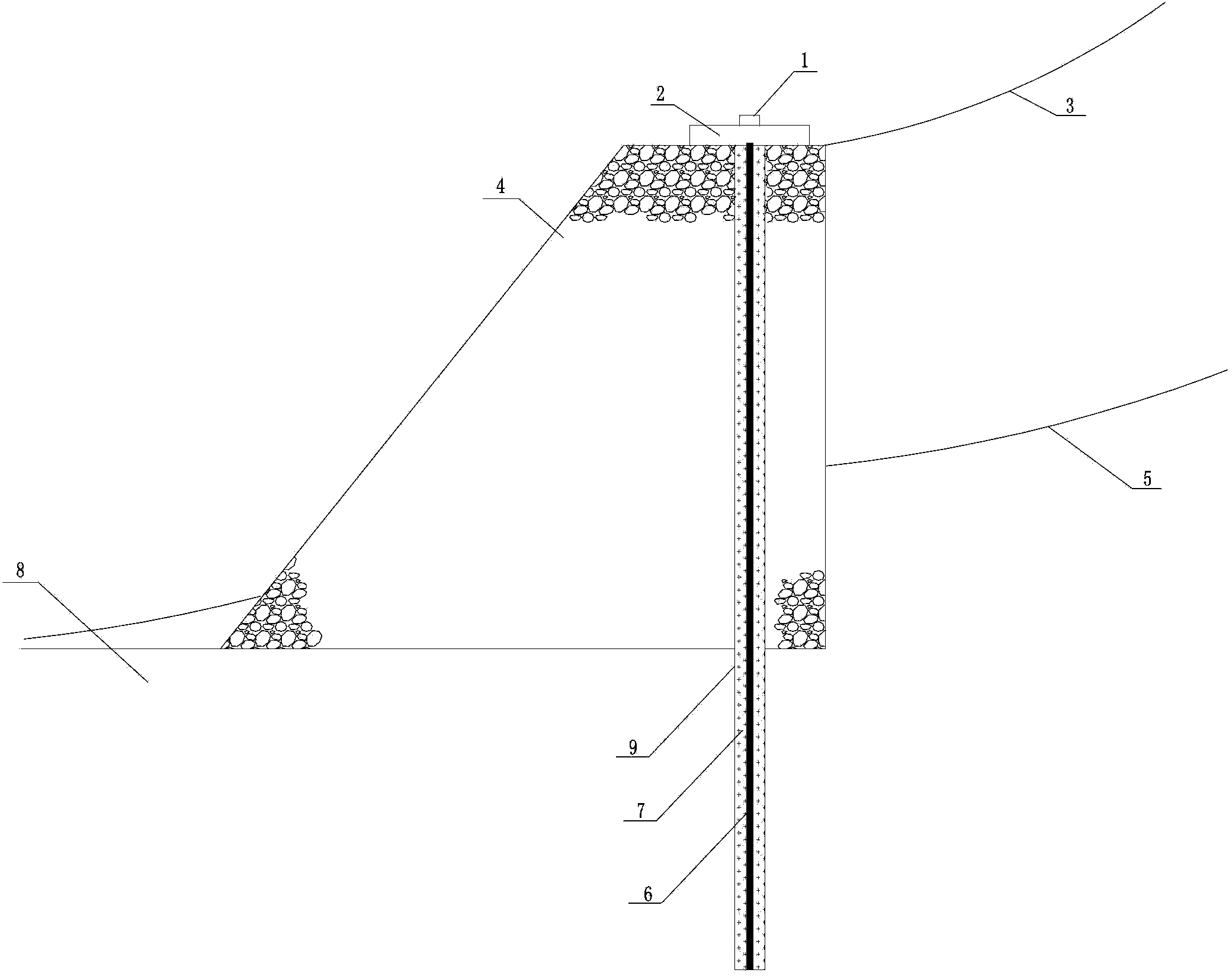

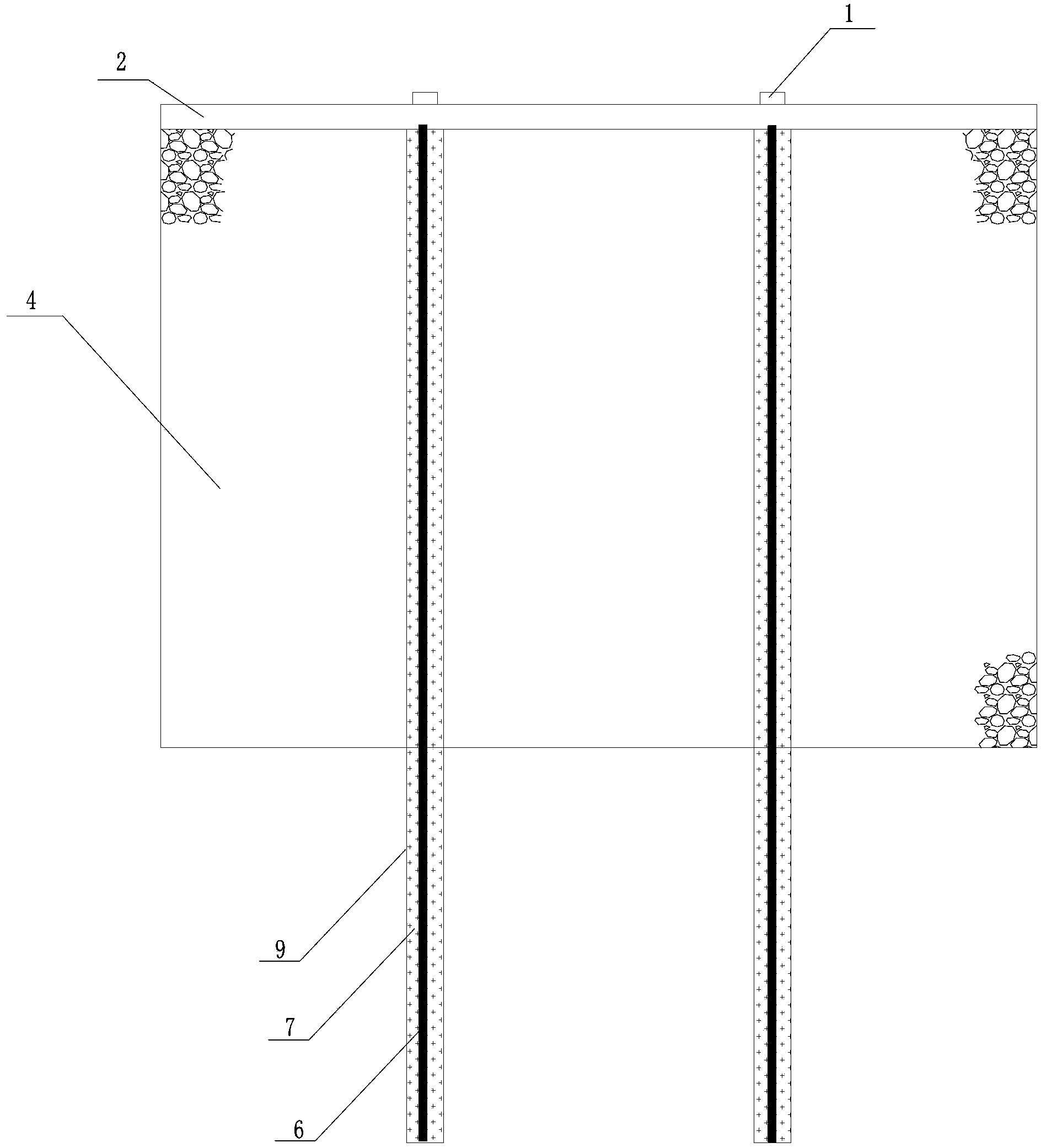

[0089] The vertical prestressed gravity composite retaining wall of the present invention includes a mortar block stone wall 4 arranged on the bedrock layer 8, and the mortar block stone wall 4 and the bedrock layer 8 are provided with anchor holes 9 along the same vertical direction. , the anchor hole 9 is provided with an anchor rod 6, cement mortar 7 is filled between the anchor rod 6 and the anchor hole 9, the top of the anchor hole 9 is provided with a concrete anchor beam 2, and the concrete anchor beam 2 is placed in the mortar block stone wall 4 The upper end of the concrete anchor beam 2 is provided with a concrete anchor head 1.

[0090] Anchor holes 9 are arranged at intervals along the road direction. The anchor rod adopts high-strength precision rail rebar, and the part of the anchor rod placed in the mortar block stone wall 4 is a free section, which is wrapped with two layers of asphalt fiberglass cloth, and the outside is wrapped with a diameter PVC pipe.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com