Extraction method of magnolia sieboldii plant volatile oil

A technology of plant volatile oil and magnolia, which is applied in the direction of essential oil/fragrance, fat production, etc., can solve the problems of organic small molecule solvent residue, unfriendly environment, etc., and achieve the effect of low cost, good extraction effect and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

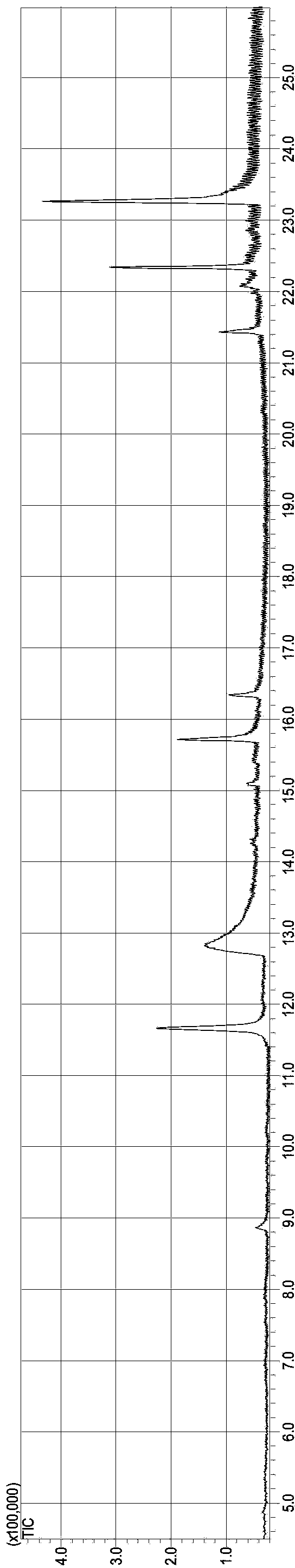

[0021] Take 1 kg of a mixture of roots, stems, leaves, flowers, and fruits of Magnolia magnolia plant, wash it, dry it, and crush it to 150 mesh, add 1 liter of 1-butyl-3-methylimidazolium bromide ionic liquid, and transfer it to carbon dioxide In the supercritical extraction tank, set the temperature at 50°C, the pressure at 30MPa, and the flow rate of carbon dioxide at 5kg / h. After extraction for 30 minutes, the extract was distilled under reduced pressure to obtain the volatile oil of Magnolia japonica plant, with an oil yield of 5%. figure 1 It is the GC-MS spectrum of the volatile oil of Magnolia japonica plant. From left to right, the peaks are sabinene (11.50%), trans-ocimene (37.01%), β-elemene (7.64%), caryophyllene (2.37%) , Myrrene (3.19%), δ-cadrene (10.54%), etc., the corresponding mass percentages are in brackets.

Embodiment 2

[0023] Take 1 kg of fallen leaves of Magnolia chinensis plant, wash, dry and crush to 300 mesh, add 2 liters of 1-butyl-3-methylimidazolium bromide ionic liquid and transfer to a carbon dioxide supercritical extraction tank, set the temperature At 50°C, pressure 30MPa, carbon dioxide flow rate 5kg / h, after 30 minutes of extraction, the extract was distilled under reduced pressure to obtain the volatile oil of Magnolia japonica plant, with an oil yield of 5%. GC-MS spectrogram shows that main component is with embodiment 1.

Embodiment 3

[0025] Take 1 kg of fallen leaves of Magnolia plant, wash, dry and crush to 300 mesh, add 2 liters of 1-decyl-3-methylimidazolium bromide ionic liquid and transfer to a carbon dioxide supercritical extraction tank, set the temperature The temperature is 30°C, the pressure is 20MPa, the flow rate of carbon dioxide is 5kg / h, and after extraction for 120 minutes, the extract is distilled under reduced pressure to obtain the volatile oil of Magnolia magnolia plant, with an oil yield of 5%. GC-MS spectrogram shows that main component is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com