Non-ester plasticizer-containing energetic material casting curing system and curing method thereof

A technology of ester plasticizer and curing method, which is applied in the direction of non-explosive/non-thermal agent components, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of reducing safety and increasing sensitivity, and achieve safety Enhanced performance, easy handling, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

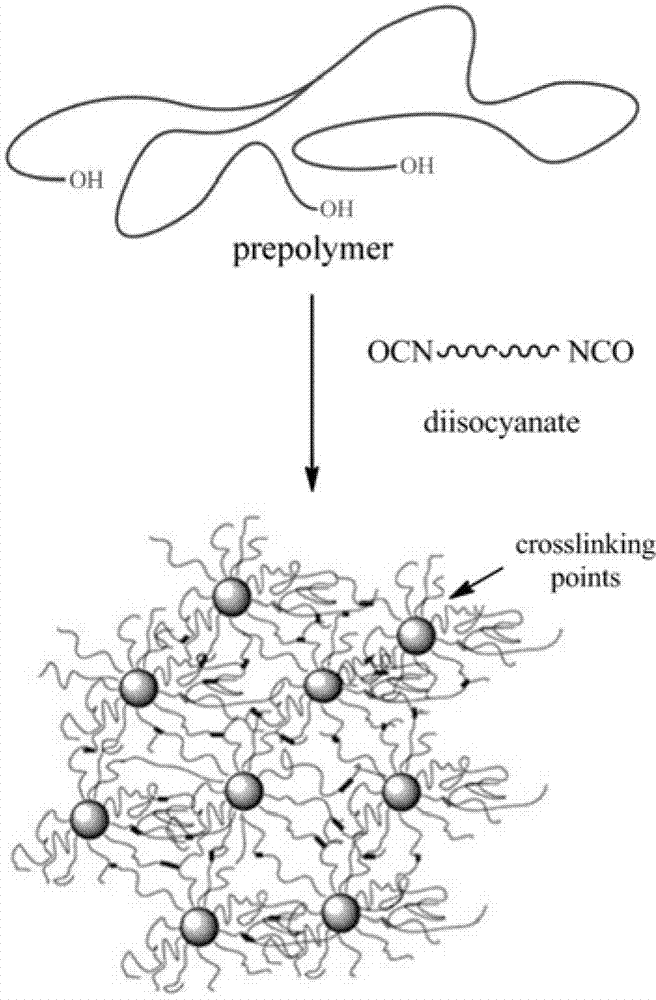

[0055] Recipe: Dissolve the curing catalyst T-12 in the plasticizer naphtha first, and prepare a solution with a concentration of 5% by weight. Take 0.08g of the solution; take 5.97g of the high molecular prepolymer HTPB (number average molecular weight 2630 , hydroxyl value 0.92mmol / g, trifunctionality), 13.44g plasticizer naphtha, 0.49g curing agent TDI, 0.02g bonding agent MAPO; the corresponding formula in parts by weight is shown in Table 1.

[0056] Curing: Add the above weight of HTPB and naphtha into a 100mL beaker, stir well for 10 minutes to form a colorless transparent homogeneous liquid; add the above weight of MAPO, stir for 20 minutes; then add 0 of the above weight of TDI, T-12 Naphtha solution, stirred for 20 minutes, poured into the pouring box, took it out after vacuuming to make it level, repeated three times, the total vacuum defoaming time was 30 minutes; then put it in the curing box for room temperature curing for 6 days, took it out, and placed it Store...

Embodiment 2

[0058] Recipe: first dissolve the curing catalyst TEPB in the plasticizer liquid paraffin to make a solution with a concentration of 5% by weight, take 0.06g of the solution; take 9.37g of high molecular weight prepolymer PET (number average molecular weight 2950, hydroxyl value 59.37mgKOH / g, trifunctionality), 9.37g plasticizer liquid paraffin, 1.16g curing agent IPDI, 0.04g bonding agent HX-874; the corresponding formula in parts by weight is shown in Table 1.

[0059] Curing: Take the above weight of PET and liquid paraffin into a 100mL beaker, stir thoroughly for 10 minutes to form a colorless transparent homogeneous liquid; add the above weight of HX-874, stir for 10 minutes; then add the above weight of IPDI, TEPB liquid Paraffin wax solution, stirred for 10 minutes and then poured into the pouring box, taken out after vacuuming to make it level, repeated three times, the total vacuum defoaming time is 60 minutes, put it in the curing box for 7 days after curing at room...

Embodiment 3

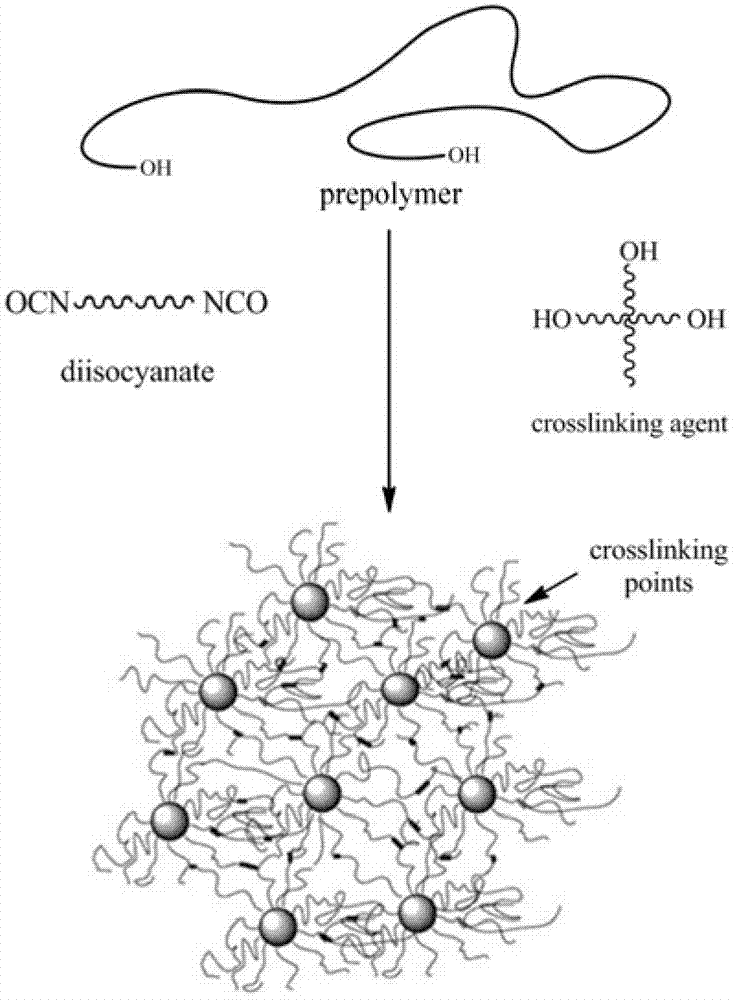

[0061] Recipe: first dissolve the curing catalyst TPB in the plasticizer BuNENA to make a solution with a concentration of 5% by weight, take 0.04g of the solution; take 7.70g of high molecular weight prepolymer PET (number average molecular weight 4215, hydroxyl value 25.92 mgKOH / g, difunctionality), 11.54g plasticizer BuNENA, 0.46g curing agent MDI, 0.2g crosslinking agent TME, 0.06g bonding agent tetraethylenepentamine; for the corresponding formula in parts by weight, see Table 1.

[0062] Curing: Add the above weight of HTPB, BuNENA and TME into a 100mL beaker, and stir thoroughly for 5 minutes to form a colorless transparent homogeneous liquid; add the above weight of tetraethylenepentamine and stir for 5 minutes; then add the above weight of MDI, The BuNENA solution of TPB, stirred for 40 minutes, poured into the pouring box, took it out after vacuuming to make it level, repeated three times, the total vacuum defoaming time was 15 minutes, put it in the curing box for 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com