Method for preparing nano zinc oxide

A technology of nano-zinc oxide and zinc powder, which is applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of many chemical reagents, high preparation costs, and cumbersome procedures, and achieve low cost and high reactivity. The effect of high and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing nano-zinc oxide, the specific steps comprising:

[0024] ① Ultrasonic dispersion: ultrasonically disperse the zinc powder in the pure water installed in the inner tank of the reactor, the volume ratio of pure water to zinc powder is 200:1, the ultrasonic temperature is 80°C, the ultrasonic frequency is 44K Hz, and the time is 60 minutes ;

[0025] ② Hydrothermal oxidation: put the above reactor liner into the reactor shell, seal the reactor and place it in an oven at 200°C for 18 hours, then cool to room temperature, and filter out the contents of the liner;

[0026] ③Vacuum drying: place the filtered substance in a vacuum oven at 60°C and dry for 1 hour to obtain the nano zinc oxide product.

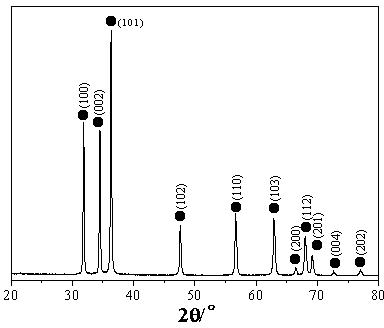

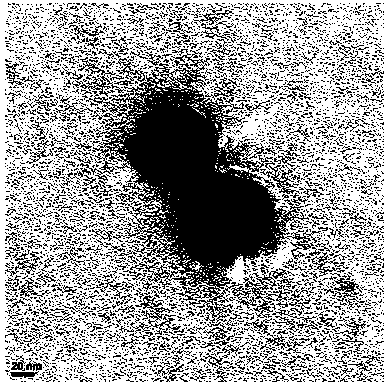

[0027] XRD and TEM characterization results show that the product is nano zinc oxide with a hexagonal wurtzite crystal structure, and the average particle size is about 70nm.

Embodiment 2

[0029] A method for preparing nano-zinc oxide, the specific steps comprising:

[0030] ① Ultrasonic dispersion: ultrasonically disperse the zinc powder in the pure water installed in the inner tank of the reactor, the volume ratio of pure water to zinc powder is 500:1, the ultrasonic temperature is 60°C, the ultrasonic frequency is 36K Hz, and the time is 30 minutes ;

[0031] ②Hydrothermal oxidation: Put the inner liner of the above reaction kettle into the outer shell of the reaction kettle, seal the reaction kettle and place it in an oven at 180°C for 48 hours, then cool to room temperature, and filter out the contents of the inner liner;

[0032] ③Vacuum drying: place the filtered substance in a vacuum drying oven at 70°C for 2 hours to obtain the nano-zinc oxide product.

[0033] XRD and TEM characterization results show that the product is nano zinc oxide with a hexagonal wurtzite crystal structure, and the average particle size is about 65nm.

Embodiment 3

[0035] A method for preparing nano-zinc oxide, the specific steps comprising:

[0036] ① Ultrasonic dispersion: ultrasonically disperse the zinc powder in the pure water installed in the inner tank of the reactor, the volume ratio of pure water to zinc powder is 300:1, the ultrasonic temperature is 70°C, the ultrasonic frequency is 42K Hz, and the time is 20 minutes ;

[0037] ② Hydrothermal oxidation: put the above reactor liner into the reactor shell, seal the reactor and place it in an oven at 180°C for 72 hours, then cool to room temperature, and filter out the contents of the liner;

[0038] ③Vacuum drying: place the filtered substance in a vacuum oven at 80°C and dry for 1 hour to obtain the product.

[0039] XRD and TEM characterization results show that the product is nano zinc oxide with a hexagonal wurtzite crystal structure, and the average particle size is about 70nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com