Combination electrode for welding gun for welding vehicle door galvanized sheet

A composite electrode, galvanized sheet technology, applied in welding medium, electrode characteristics, welding equipment and other directions, can solve the problems of easy welding, poor welding performance, etc., to achieve the effect of not easy to open welding, improve welding performance, and avoid sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

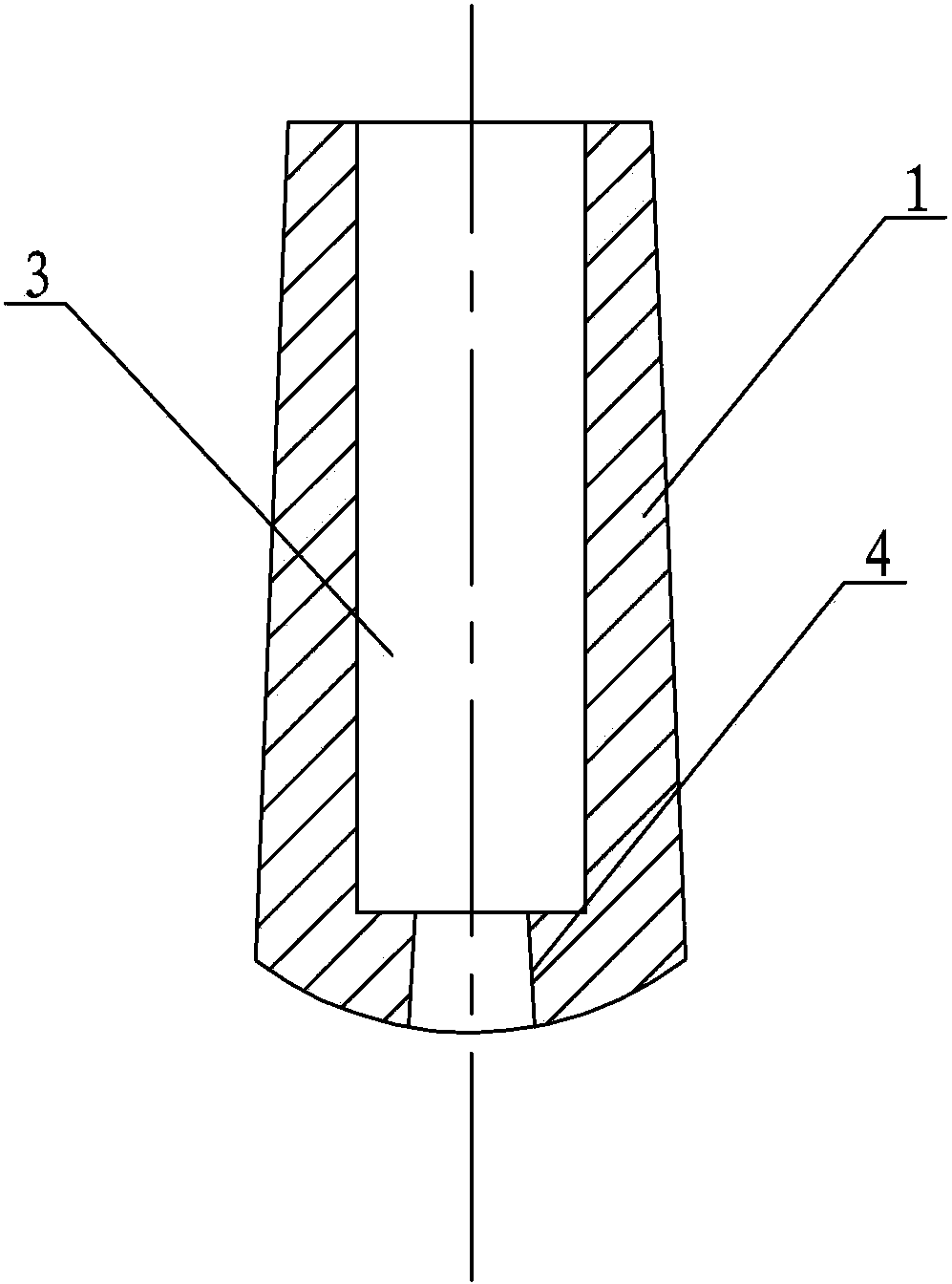

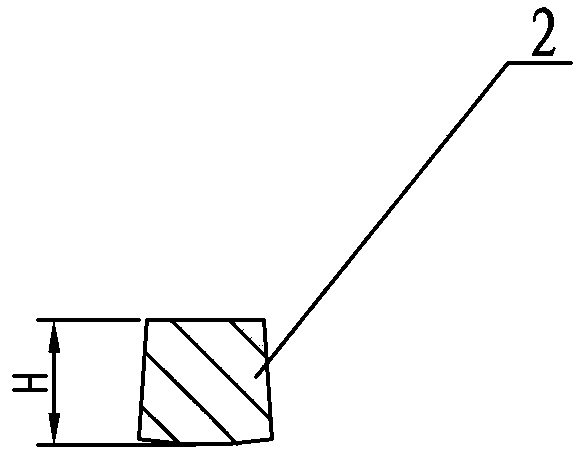

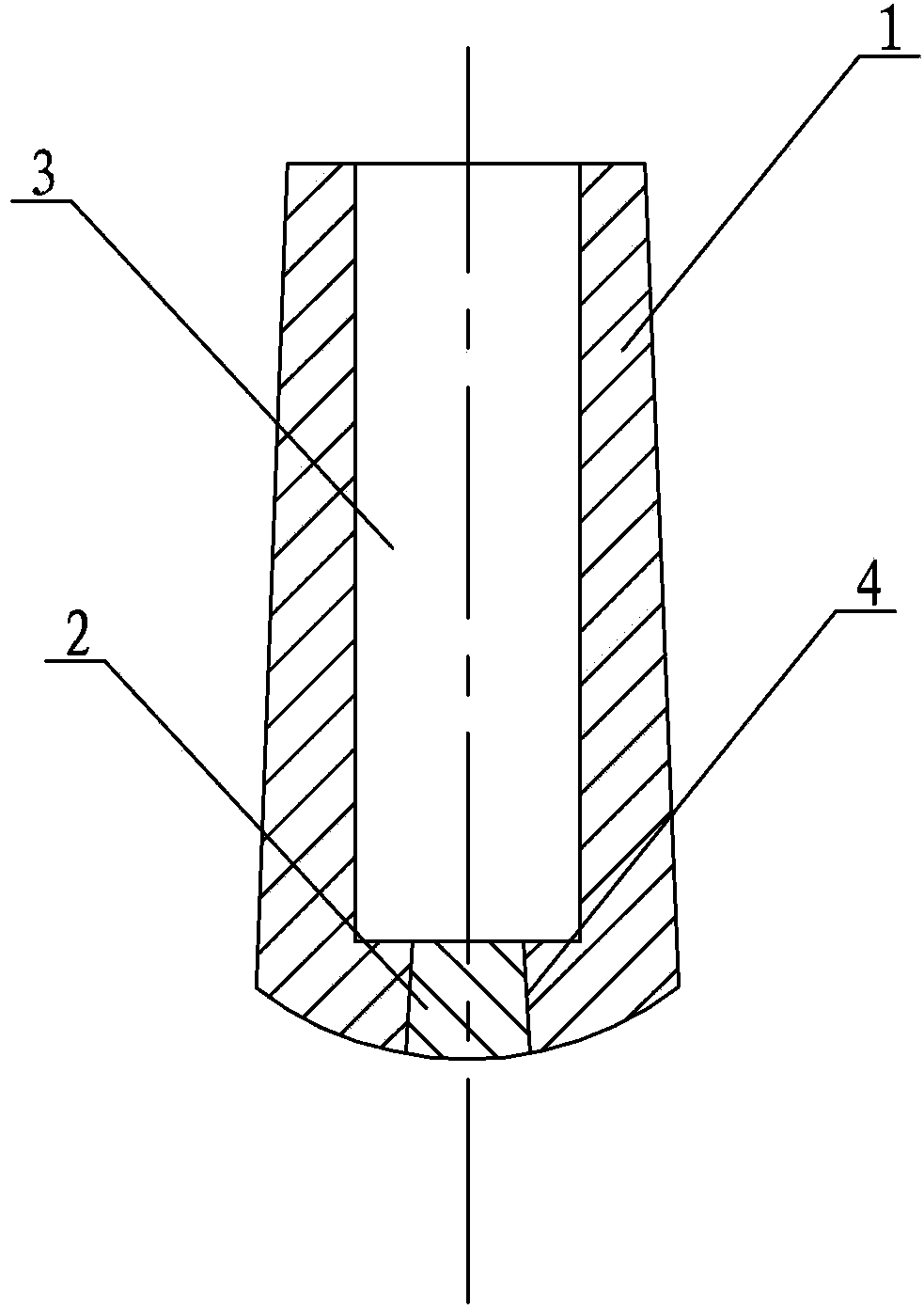

[0012] Specific implementation mode one: combine Figure 1-Figure 3 Describe this embodiment, the special compound electrode of the welding torch of welding car door galvanized sheet of this embodiment comprises chromium-zirconium copper electrode cap 1, and the top of chromium-zirconium copper electrode cap 1 is provided with cooling hole 3 along its axis, and chromium-zirconium copper electrode cap 1 The bottom of the bottom is provided with a through hole 4, the through hole 4 is a tapered hole gradually expanding from top to bottom, the through hole 4 communicates with the cooling hole 3, the upper end aperture of the through hole 4 is smaller than the aperture of the cooling hole 3, the composite electrode It also includes a tungsten pole 2, the outer wall of the tungsten pole 2 gradually expands from top to bottom, the tungsten pole 2 is arranged in the through hole 4, and the outer side wall of the tungsten pole 2 and the inner side wall of the through hole 4 have an int...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination Figure 1-Figure 3 The present embodiment will be described. The taper of the outer wall of the tungsten electrode 2 of the present embodiment is 3°. Such arrangement is convenient to cooperate with the through hole 4 on the chrome-zirconium copper electrode cap 1 . Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Specific implementation mode three: combination Figure 1-Figure 3 The present embodiment will be described. The smallest end diameter of the tungsten electrode 2 of the present embodiment is 7 mm. Such arrangement is convenient to cooperate with the through hole 4 on the chrome-zirconium copper electrode cap 1 . . Other compositions and connections are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com