Thickness-controllable roller brush for metal wire drawing and use method of thickness-controllable roller brush

A technology of metal wire drawing and thickness, which is applied to metal processing equipment, parts of grinding machine tools, machine tools suitable for grinding workpiece planes, etc., can solve the problems of reducing the utilization rate of wire drawing equipment and inconvenient drawing process of workpieces, and achieve improvement Scope of application, not easy to soften and deform, and the effect of reducing the generation of a large amount of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

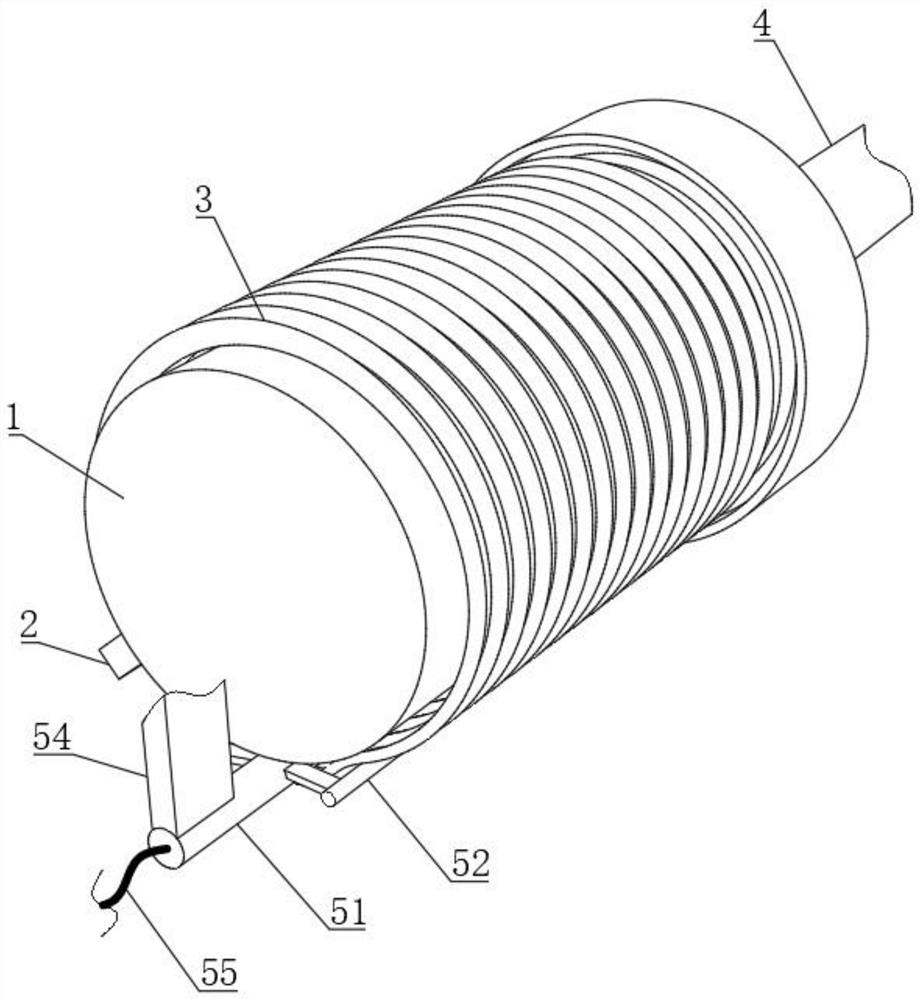

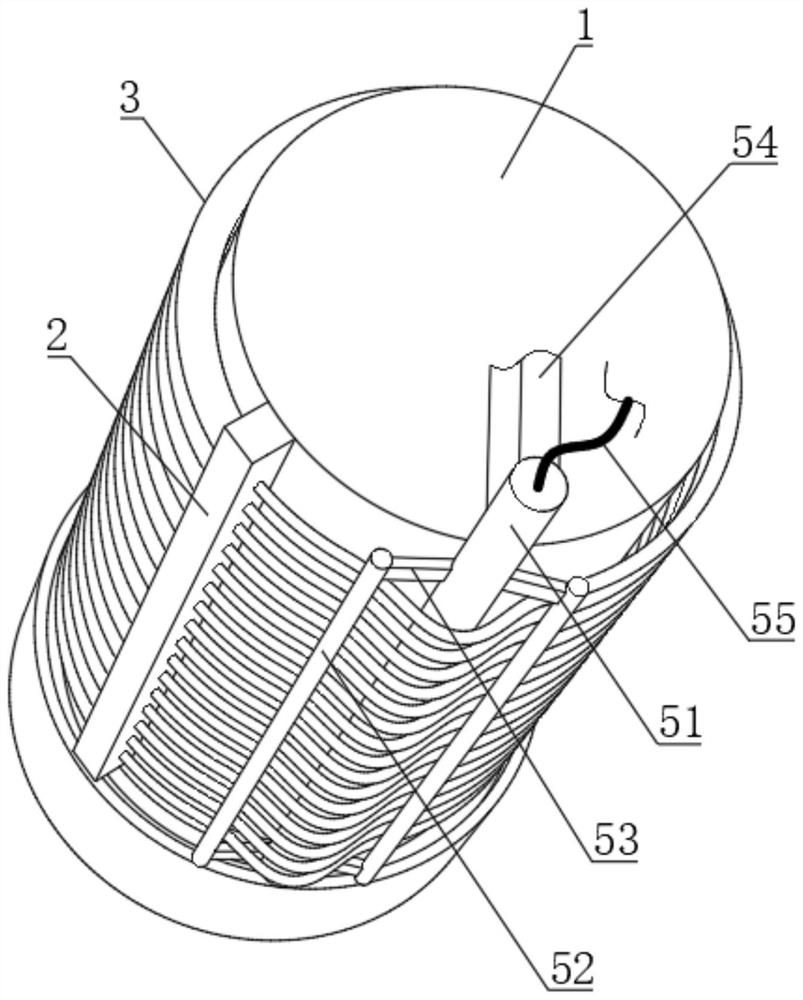

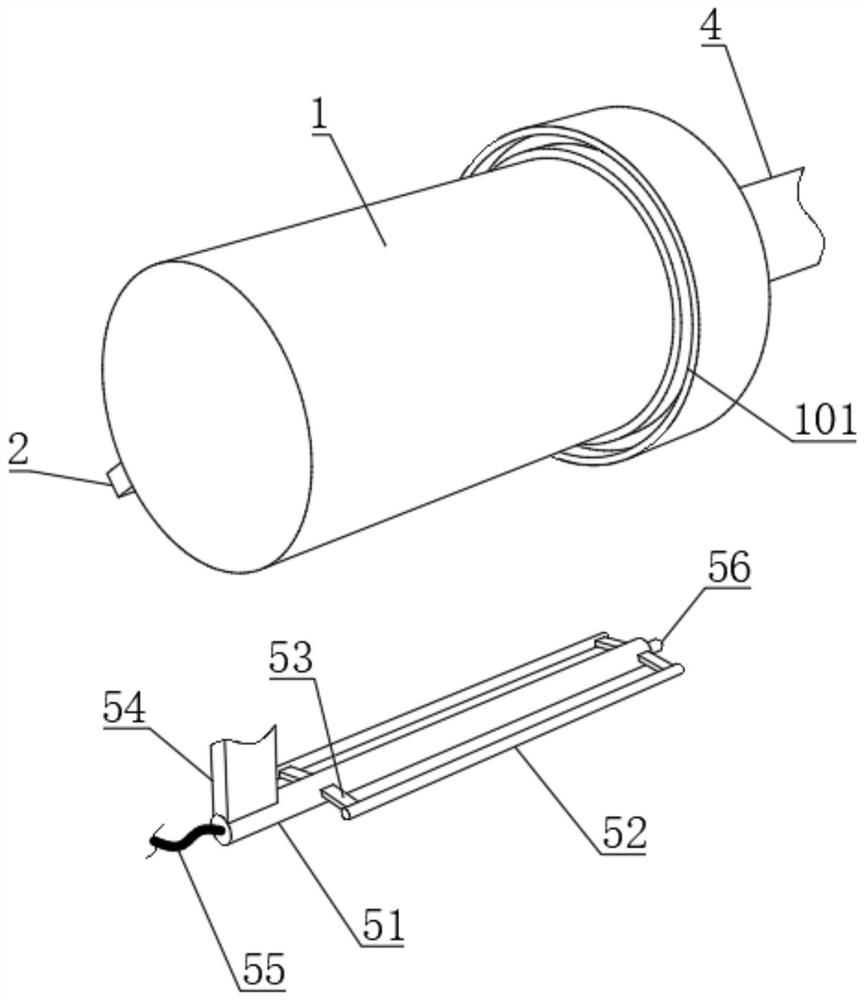

[0045] see figure 1 , figure 2 and Figure 7 , a roller brush for metal wire drawing with controllable thickness, including a T-shaped roller 1, the outer side of the T-shaped roller 1 is provided with a plurality of uniformly distributed variable diameter steel wires 3, and the outer end of the T-shaped roller 1 is fixedly connected with a horizontal plate 2. The head and tail ends of the reducing wire 3 are respectively fixedly connected with a pair of side ends of the horizontal plate 2, and one side end of the T-shaped roller 1 is fixedly connected with a connecting rod 4, and the end of the connecting rod 4 away from the T-shaped roller 1 is connected with the execution The output of the motor is fixedly connected ( Figure 7 The middle b represents the execution motor), a wire adjusting frame is provided on the lower side of the T-shaped roller 1, and the adjusting frame includes a main pressing rod 51 and a pair of auxiliary pressing rods 52, and a pair of auxiliary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com