Line outgoing casing pipe applied to high-pressure superconductivity electrical equipment

A technology of outlet bushing and power equipment, which is applied in the direction of cable accessories of low-temperature cables, lead-in/through-type insulators, insulators, etc., which can solve the problems of large partial discharge and low withstand voltage of ordinary FRP bushings, and achieve partial discharge Low weight, high mechanical stability and thermal stability, good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

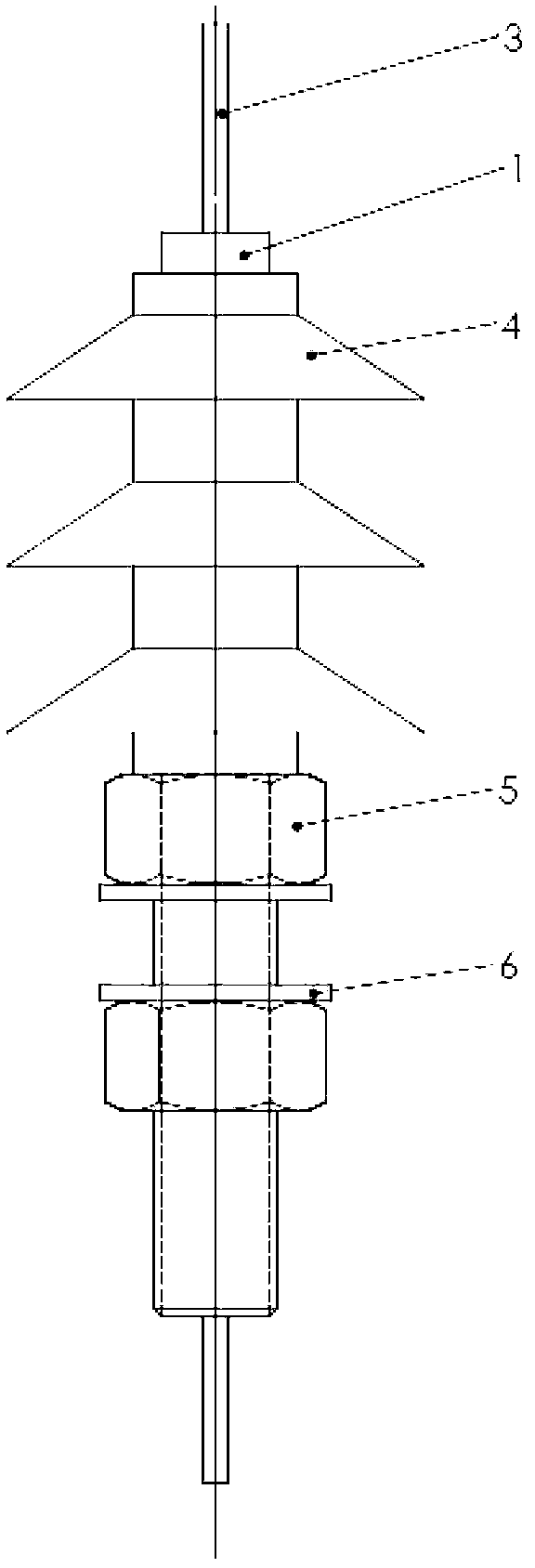

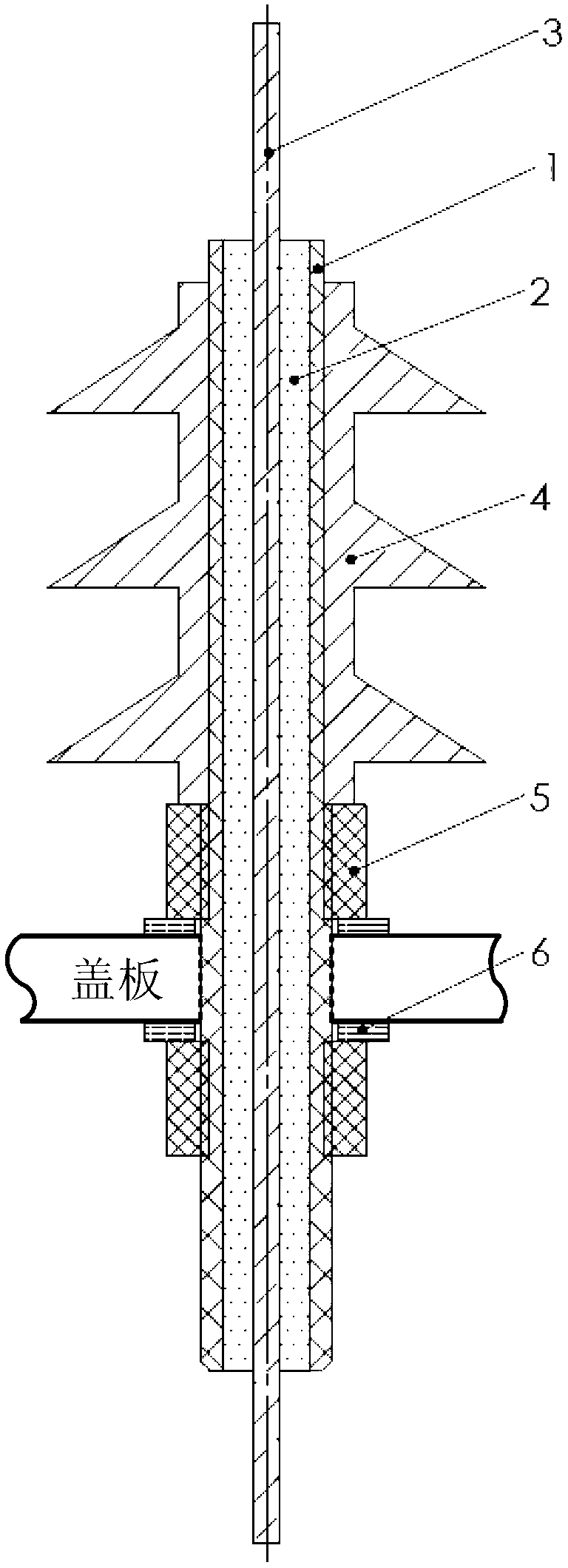

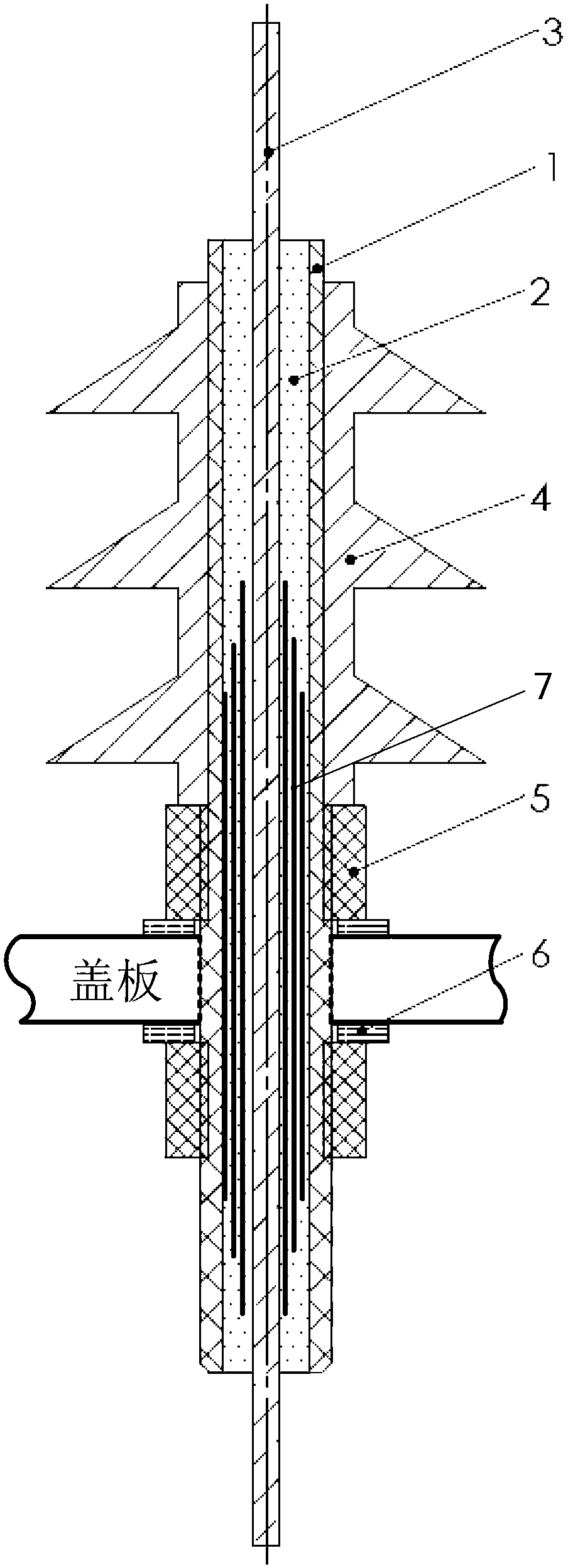

[0019] The outlet bushing of the present invention is mainly composed of a glass fiber reinforced plastic sheath 1, a low-temperature glue-impregnated paper 2, a lead wire 3 and an umbrella shed 4 and the like. The outlet sleeve is fixedly installed on the cover plate of the cryogenic container through a clamping mechanism composed of a fastening nut 5 and a sealing washer 6 . FRP sheath 1, low-temperature glue-impregnated paper 2, lead wire 3 and shed 4 are all concentric cylindrical structures, and from inside to outside are lead wire 3, low-temperature glue-impregnated paper 2, FRP sheath 1 and shed 4. The upper ends of the FRP sheath 1, the low-temperature glue-impregnated paper 2 and the lead wires are located at room temperature, and the lower ends of the FRP sheath 1, the low-temperature glue-impregnated paper 2 and the lead wires 3 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com