Soft measurement method for granularity of cement raw material grinded by ball mill

A technology for cement raw meal and soft measurement, which can be used in measurement devices, particle size analysis, neural learning methods, etc., and can solve problems such as slow convergence speed and low estimation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

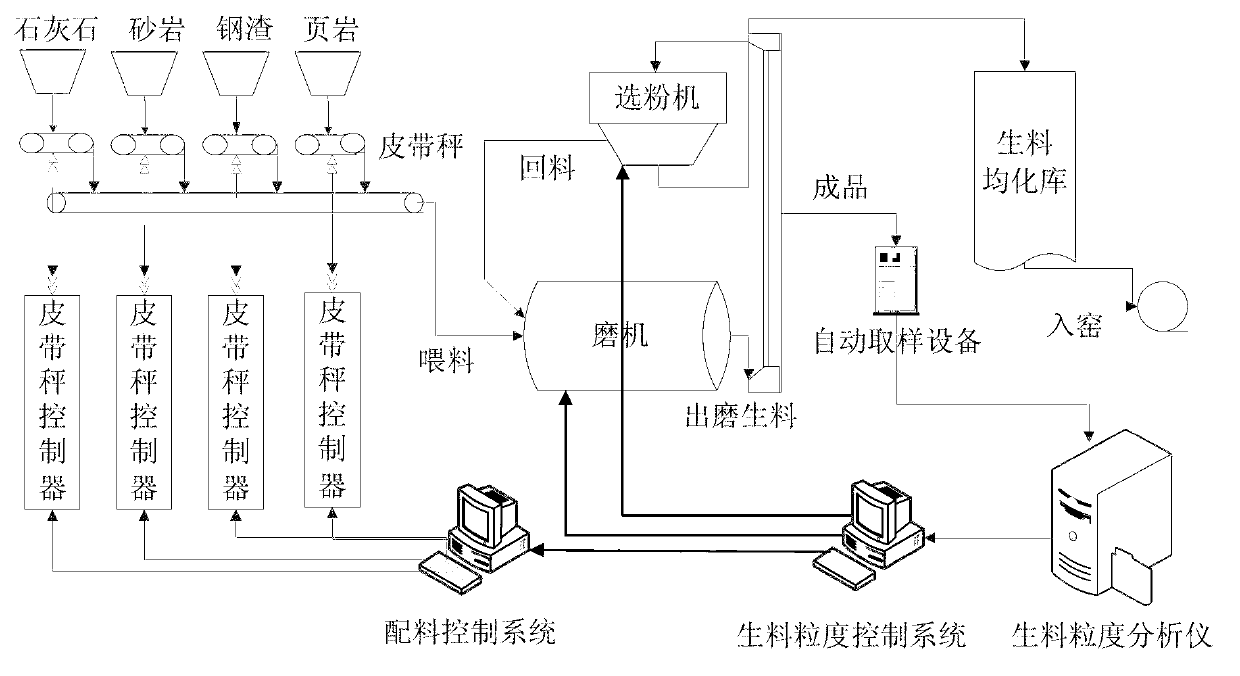

[0053] A kind of ball mill cement raw material grinding particle size soft measurement method of the present invention comprises the following steps:

[0054] 1. Selection of auxiliary variables: The speed of the classifier, the feeding flow rate, the air pressure at the inlet of the classifier, and the load of the classifier are used as the auxiliary variables of the soft measurement model for the particle size of the finished product;

[0055] 2. Data preprocessing: mainly including screening, filtering and standardizing the original data.

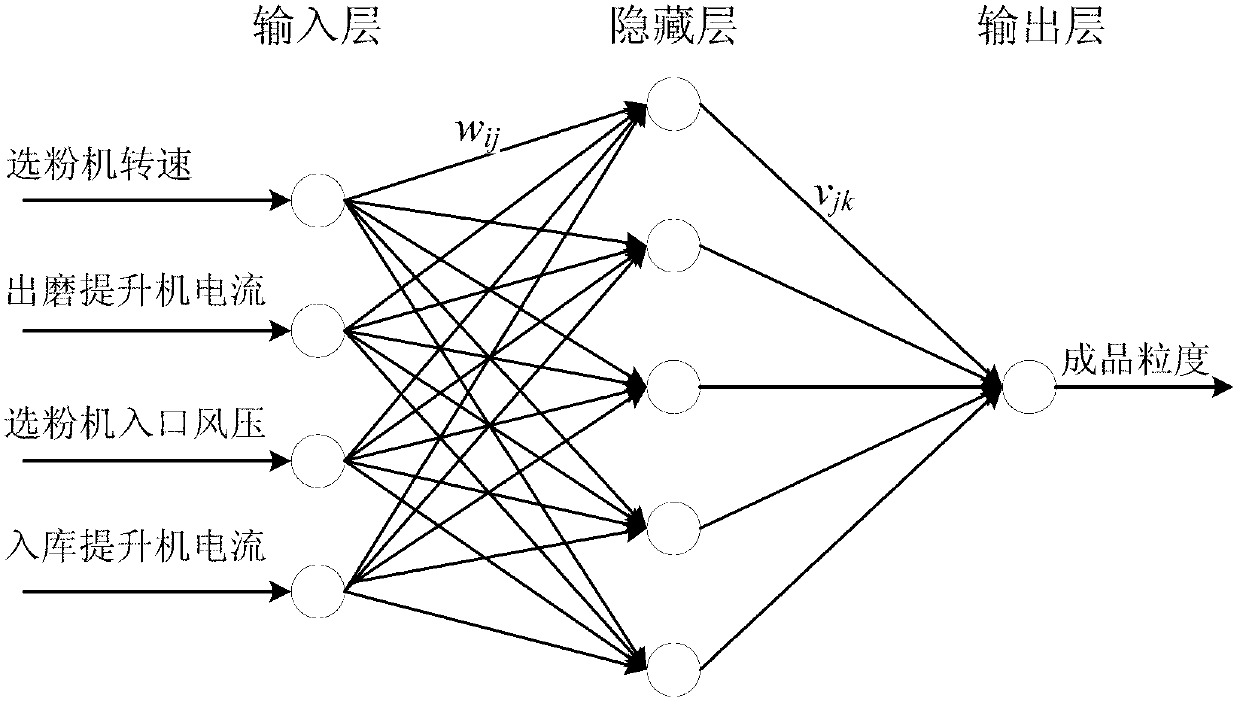

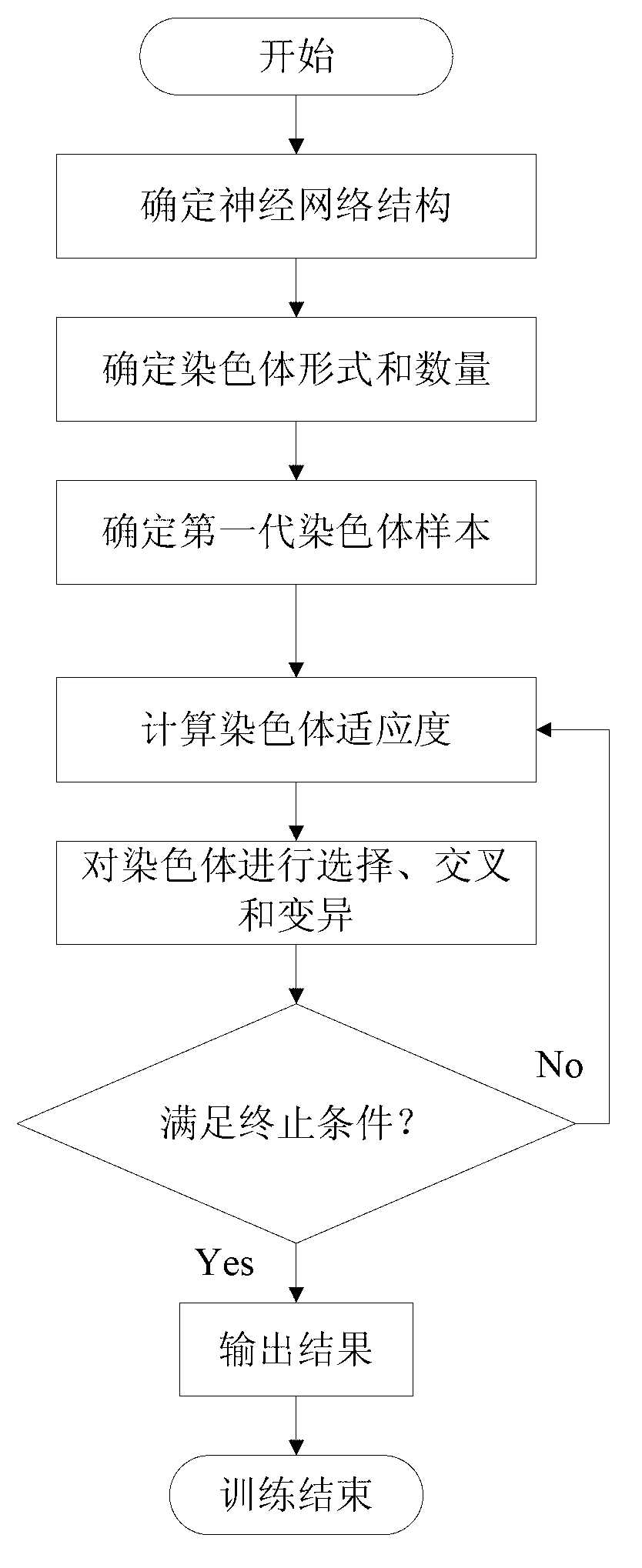

[0056] 3. Soft sensor modeling based on GA-NN (genetic algorithm optimized neural network): The present invention proposes a learning algorithm for neural network training based on the GA (Genetic Algorithm-genetic algorithm) algorithm. The weights that need to be adjusted in the neural network are regard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com