Preparation method of ionic liquid electrodeposition copper/indium/gallium/selenium CIGS thin-film materials

A technology of ionic liquid and copper indium gallium selenide, which is applied in the field of materials, achieves the effects of good process stability and repeatability, easy preparation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] Embodiment 1: The CIGS thin film of this embodiment is prepared by electrodeposition of ionic liquid, and the specific steps are as follows:

[0017] 1) Prepare the electroplating solution with the following ratio: ionic liquid 1-butyl-3-methylimidazolium trifluoromethanesulfonate (BMIm-OTF) 15~40ml, copper chloride 5~25mmol / L, indium chloride 10 ~40mmol / L, gallium chloride 2~7mmol / L, selenium chloride 15~55mmol / L.

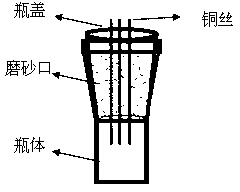

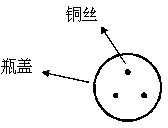

[0018] 2) After adding the above raw materials into a closed electrolytic cell in an argon atmosphere glove box, stir at a constant temperature (30-80 °C) at a constant speed (100-250 r / min) for 2-24 h.

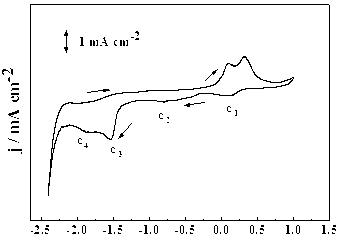

[0019] 3) Select the platinum sheet as the counter electrode and the platinum wire as the reference electrode, and conduct CIGS film electrodeposition on the substrate of the working electrode under the conditions of voltage of -1.4~-2.2V and temperature of 30~80℃ for 1~ 4h.

[0020] In this embodiment, the electroplating solution is prepared by the foll...

specific Embodiment approach 2

[0031] Specific embodiment two: the difference between this embodiment and specific embodiment one is: weigh 13.4~67.2mg copper chloride, 44.2~176.9mg indium chloride, 13.5~47.3mg gallium chloride and 66.2~242.8mg selenium chloride added to the electrolytic tank.

specific Embodiment approach 3

[0032] Specific embodiment three: This embodiment provides a method for preparing a CIGS thin film, and the specific steps are as follows:

[0033] 1. Measure 20ml of ionic liquid 1-butyl-3-methylimidazolium trifluoromethanesulfonate (BMIm-OTF), weigh 26.9mg copper chloride, 66.4mg indium chloride, 16.9mg gallium chloride and 88.3 mg of selenium chloride is placed in an electrolytic cell, stirred at a temperature of 40° C. for 2 hours to obtain a mixed liquid;

[0034] 2. Raise the temperature of the mixed liquid obtained in step 1 to 50°C, and connect the three-electrode system after constant temperature;

[0035]3. Electrodeposit the system obtained in step 2 for 2 hours under the condition of a voltage of -2.0V, and obtain a CIGS coating layer electrodeposited on the Ni sheet.

[0036] The stoichiometric ratio of the CIGS thin film coating obtained in the present embodiment is: Cu 1.00 In 0.83 Ga 0.23 Se 1.64 .

[0037] Copper chloride and indium chloride used in this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com