Zone melting and directional solidifying method used for volatile element alloy

A technology of directional solidification and zone melting, applied in self-zone melting method, chemical instruments and methods, improvement of process efficiency, etc., can solve the problem that the actual composition of the alloy deviates from the design composition, the distribution of axial composition is uneven, and the loss of volatile elements increases. and other problems, to achieve uniform distribution of axial components, great practical application value, and the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] Example 1: Ni 50 mn 34 In 16 (at.%) alloy

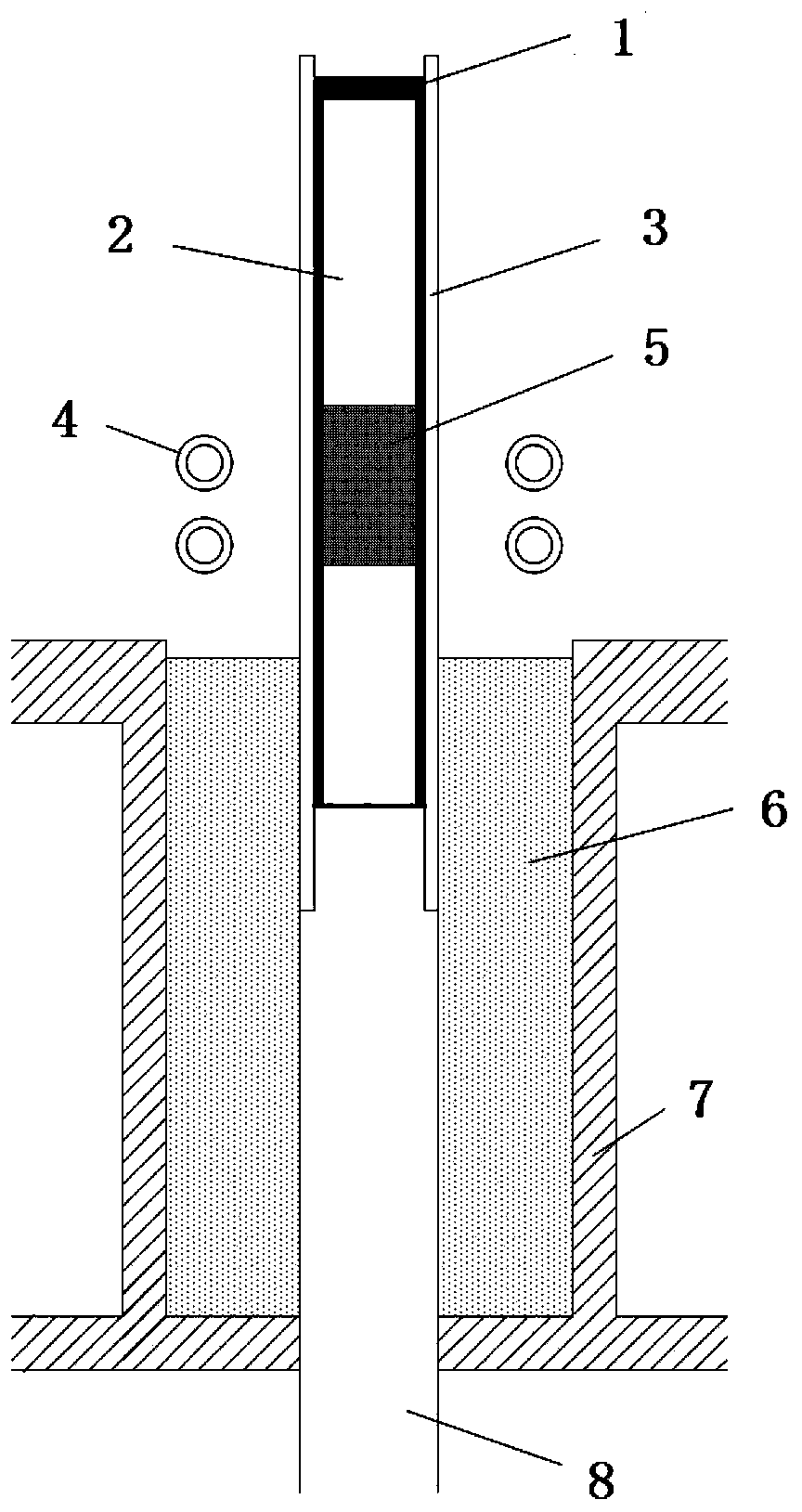

[0029] The present invention will be further described below in conjunction with the longitudinal sectional schematic diagram of the directional solidification device used in the present invention. The directional solidification device includes: induction coil 4 , liquid metal 6 , circulating cooling water 7 , and pull rod 8 . In addition, the schematic diagram also includes: molten slag 1 , alloy initial rod 2 , directional solidification crucible 3 , and alloy melting zone 5 .

[0030] The working process of the above-mentioned directional solidification device is as follows: the initial alloy rod 2 is vertically placed in the directional solidification crucible 3, the gap between the initial alloy rod 2 and the directional solidification crucible 3 is filled with a slagging agent, and the heating by the induction coil 4 , so that the initial alloy bar 2 area is melted to form an alloy melting zone 5, and the slagging ag...

example 2

[0038] Example 2: La(Fe 0.86 Si 0.14 )13 (at.%) alloy

[0039] La(Fe 0.86 Si 0.14 ) 13 (at.%) alloy exhaustive zone melting directional solidification steps are as follows:

[0040] 1. Alloy La(Fe 0.86 Si 0.14 ) 13 (at.%). The raw materials for configuring the alloy are: pure lanthanum, pure iron, and pure silicon. The purity of the above three raw materials is 99% (by mass percentage), and the total weight of the alloy is 40g. Since the element La in the alloy is volatile, the proportion of La element should be increased. Set the burning loss rate to 4%, according to La(Fe 0.86 Si 0.14 ) 13 The theoretical weight of the La element in the alloy is increased by 4% to cope with the loss in the arc melting process.

[0041] 2. Arc melting. Use a vacuum non-consumable electric arc furnace, first evacuate to 3.0×10 -2 ~5.0×10 -2 Pa, after filling the furnace with argon, then vacuumize to 3.0×10 -3 ~5.0×10 -3 Pa, then filled with argon gas to 0.05MPa and then heate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com