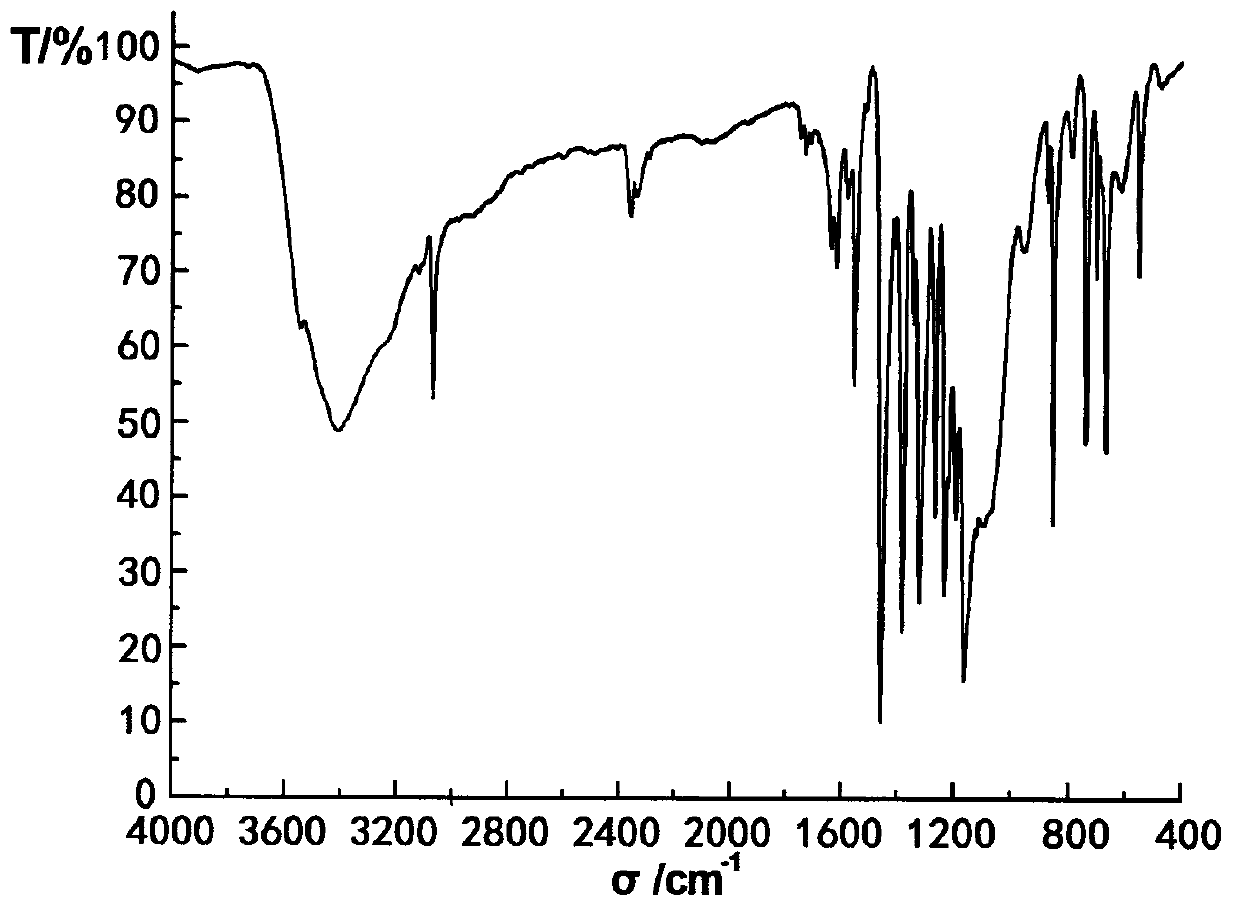

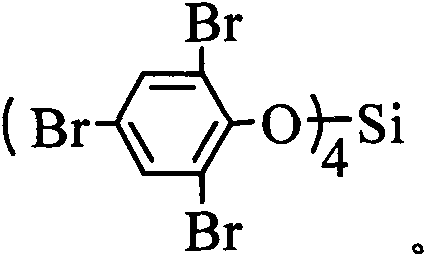

Flame retardant tetra(tribromophenyl) silicate esterification compound and preparation method thereof

A technology of ester compound and tetrasilicic acid, which is applied in the direction of silicon organic compounds, can solve the problems of difficulty in finding ideal substitutes, high comprehensive cost performance, etc., and achieve excellent plasticizing effect, high decomposition temperature, and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 In a 500ml four-necked flask equipped with a stirrer, a thermometer, a dropping funnel and a high-efficiency reflux condenser and a series hydrogen chloride absorption device and a drying tube at the top of the condenser, nitrogen protection was introduced, and 150ml xylene was added and 8.50g (0.05mol) silicon tetrachloride, start stirring, at 30°C, add 66.16g (0.2mol) tribromophenol, then raise the temperature to 45°C for 1h, keep the temperature for 1h, then raise the temperature to 105°C, keep the temperature for reaction 11 hours, after the hydrogen chloride is released, cool down to 40°C, install an extremely stretchable soft seal on the top of the condenser tube, inject ethylene oxide under the liquid surface to remove traces of free acid in the reaction solution, and test the reaction solution. When the pH=5-6 is the end point, the solvent (recycled) and a small amount of low boiling point substances are distilled off under reduced pressure to obtain th...

Embodiment 2

[0028] Example 2 In a 500ml four-neck flask equipped with a stirrer, a thermometer, a dropping funnel and a high-efficiency reflux condenser and a series hydrogen chloride absorption device and a drying tube on the upper mouth of the condenser, nitrogen protection was introduced, and 150ml of dioxygen was added. Hexacyclic and 8.50g (0.05mol) silicon tetrachloride, start stirring, at 30°C, add 66.16g (0.2mol) tribromophenol, then raise the temperature to 45°C for 1h, keep the temperature for 1h, then raise the temperature to 100°C, Insulate and react for 12 hours. After the hydrogen chloride is released, cool down to 40°C. Install an extremely flexible soft seal on the top of the condenser tube. Put ethylene oxide under the liquid surface to remove traces of free acid in the reaction solution and test the reaction. The pH of the solution is 5-6 as the end point, and the solvent (recycled) and a small amount of low boiling point substances are removed by distillation under reduc...

Embodiment 3

[0029] Example 3 In a 500ml four-neck flask equipped with a stirrer, a thermometer, a dropping funnel and a high-efficiency reflux condenser and a series hydrogen chloride absorption device and a drying tube at the top of the condenser, nitrogen protection was introduced, and 150ml of chlorobenzene was added. and 8.50g (0.05mol) of silicon tetrachloride, start stirring, at 30°C, add 66.16g (0.2mol) of tribromophenol, then raise the temperature to 45°C for 1h, keep the reaction for 1h, then raise the temperature to 115°C, keep the reaction 9h, after the hydrogen chloride is released, lower the temperature to 40°C, install an extremely stretchable soft seal at the top of the condenser tube, inject ethylene oxide under the liquid surface to remove traces of free acid in the reaction solution, and test the reaction solution. When the pH=5-6 is the end point, the solvent (recycled) and a small amount of low boiling point substances are distilled off under reduced pressure to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com