A kind of polymer modified rubber mortar for building leveling layer and its construction method

A technology of modified rubber and construction method, which is applied in building construction, building material processing, construction and other directions, can solve the problems of tires not being recycled, insoluble in organic solvents, and not easy to rot, etc., and achieves the chloride ion permeability coefficient. Reduced, significant flexibility benefits, increased flexibility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

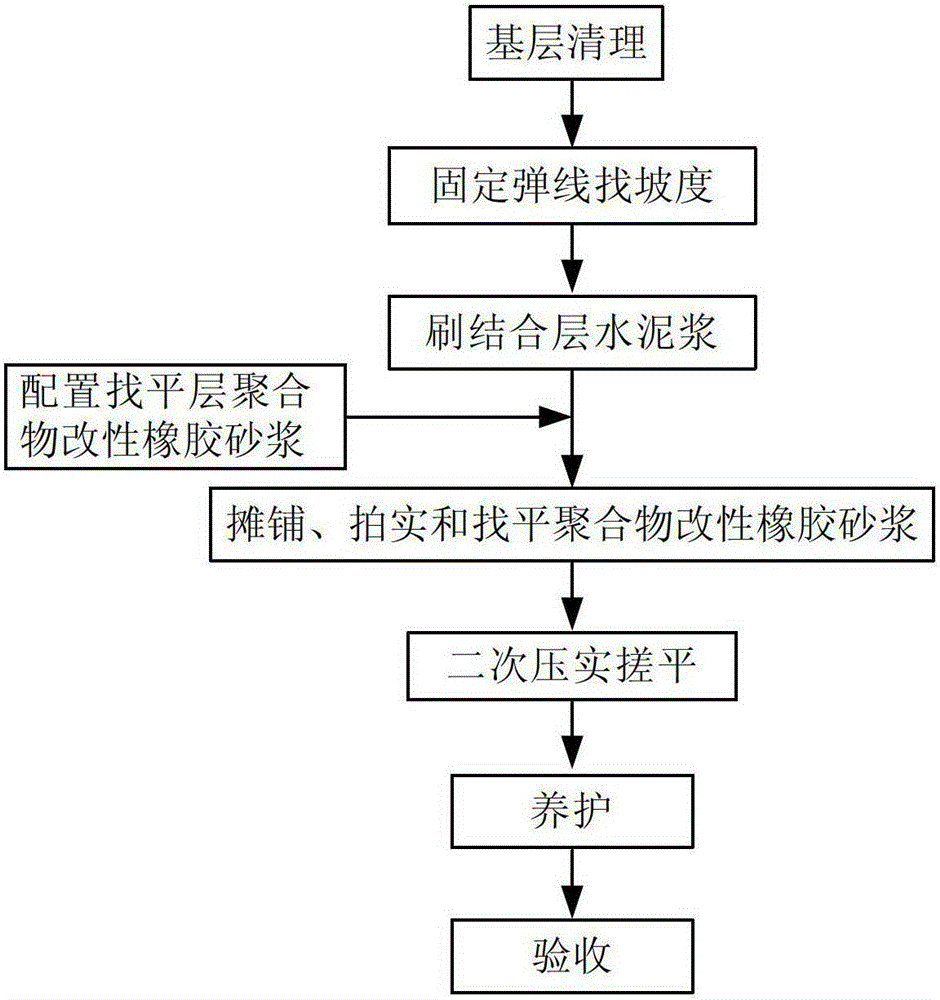

Method used

Image

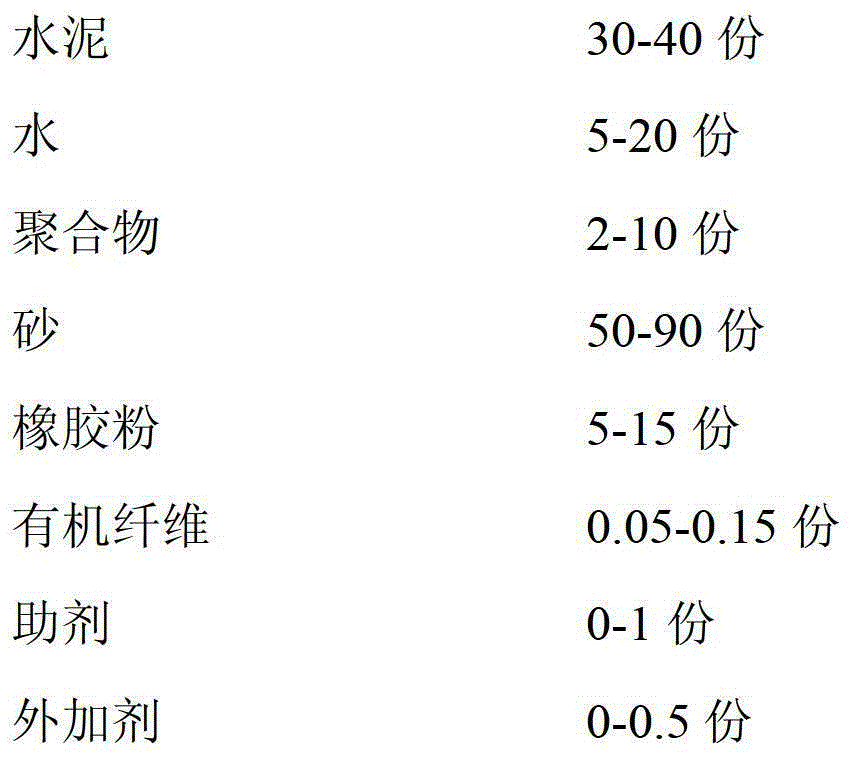

Examples

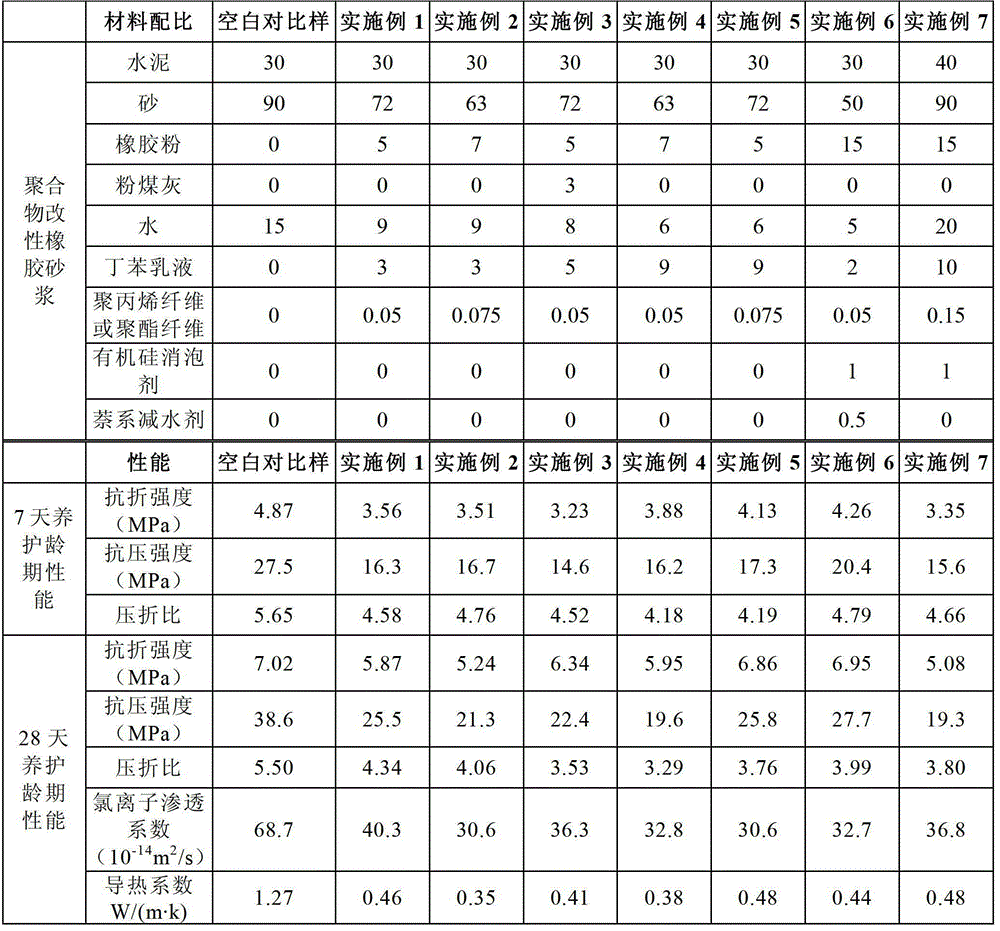

Embodiment 1

[0066] Material composition: 30 parts of cement, 72 parts of sand, 5 parts of rubber powder, 9 parts of water, 3 parts of styrene-butadiene emulsion, and 0.05 parts of polypropylene fiber. The compressive strength is 16.3MPa, the fold ratio is 4.58, the polymer modified rubber mortar prepared has a 28-day flexural strength of 5.87MPa, a compressive strength of 25.5MPa, and a fold ratio of 4.34, and the 28-day chloride ion permeability coefficient of the mortar is 40.3× 10 -14 m 2 / s, the thermal conductivity is 0.46W / m·k.

Embodiment 2

[0068] Material composition: 30 parts of cement, 63 parts of sand, 7 parts of rubber powder, 9 parts of water, 3 parts of styrene-butadiene emulsion, 0.075 parts of polyester fiber, the flexural strength of the prepared polymer modified rubber mortar for 7 days is 3.51MPa, The compressive strength is 16.7MPa, the fold ratio is 4.76, the polymer modified rubber mortar prepared has a 28-day flexural strength of 5.24MPa, the compressive strength is 21.3MPa, the fold ratio is 4.06, and the 28-day chloride ion permeability coefficient of the mortar is 30.6 ×10 -14 m 2 / s, the thermal conductivity is 0.35W / m·k.

Embodiment 3

[0070] Material composition: 30 parts of cement, 72 parts of sand, 5 parts of rubber powder, 3 parts of fly ash (mineral admixture), 8 parts of water, 5 parts of styrene-butadiene emulsion, and 0.05 parts of polypropylene fiber. The flexural strength of the rubber mortar for 7 days was 3.23MPa, the compressive strength was 14.6MPa, and the folding ratio was 4.52. 3.53, the chloride ion permeability coefficient of the mortar for 28 days is 36.3×10 -14 m 2 / s, the thermal conductivity is 0.41W / m·k.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flow consistency | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com