Numerical control flat tube polisher and polishing line assembly with same

A technology of grinding machine and pneumatic grinding machine, which is applied to machine tools, grinding machines, grinding workpiece supports and other directions suitable for grinding workpiece planes, to achieve the effects of high use and promotion value, efficient grinding, easy control of work process and work accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

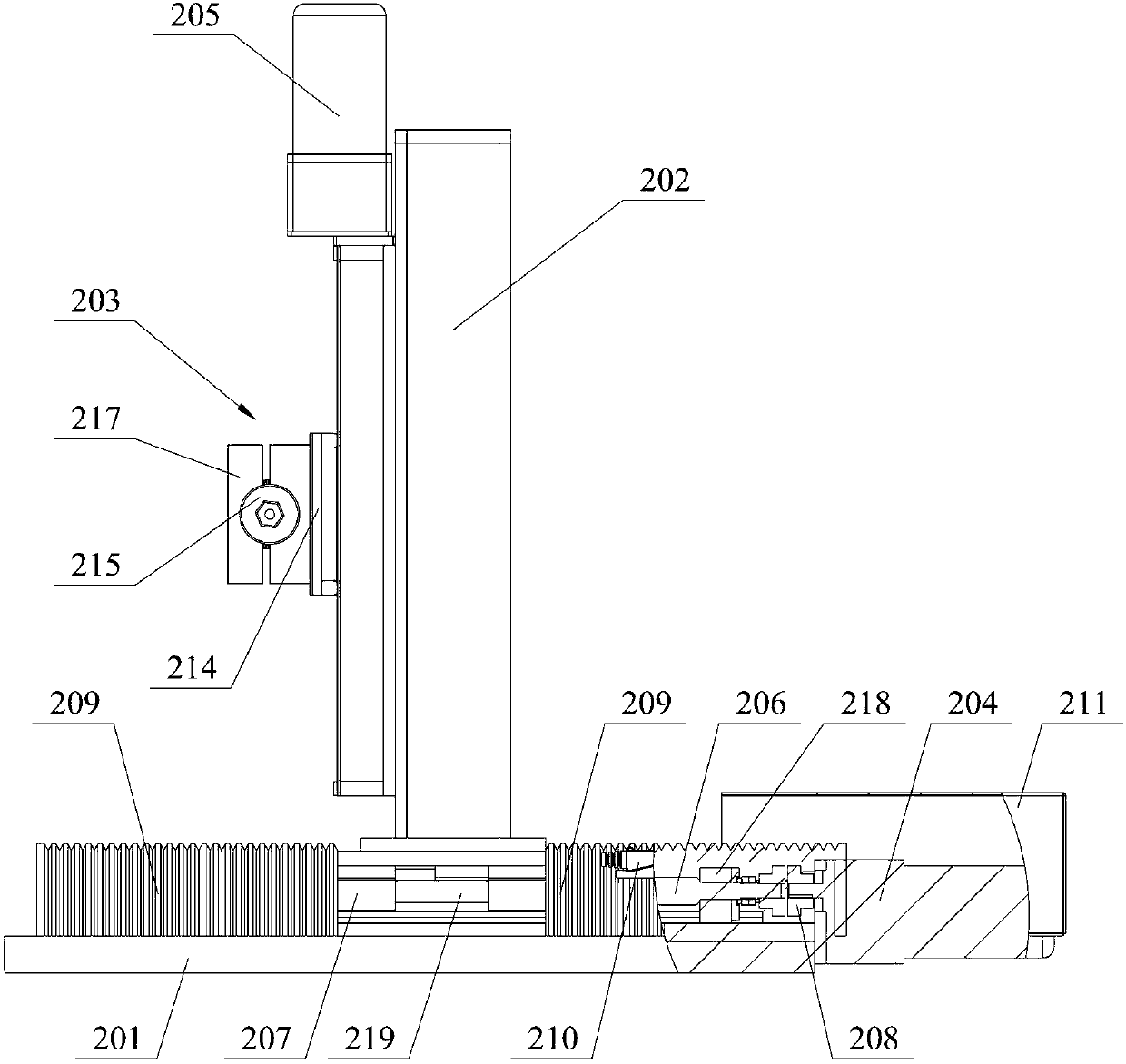

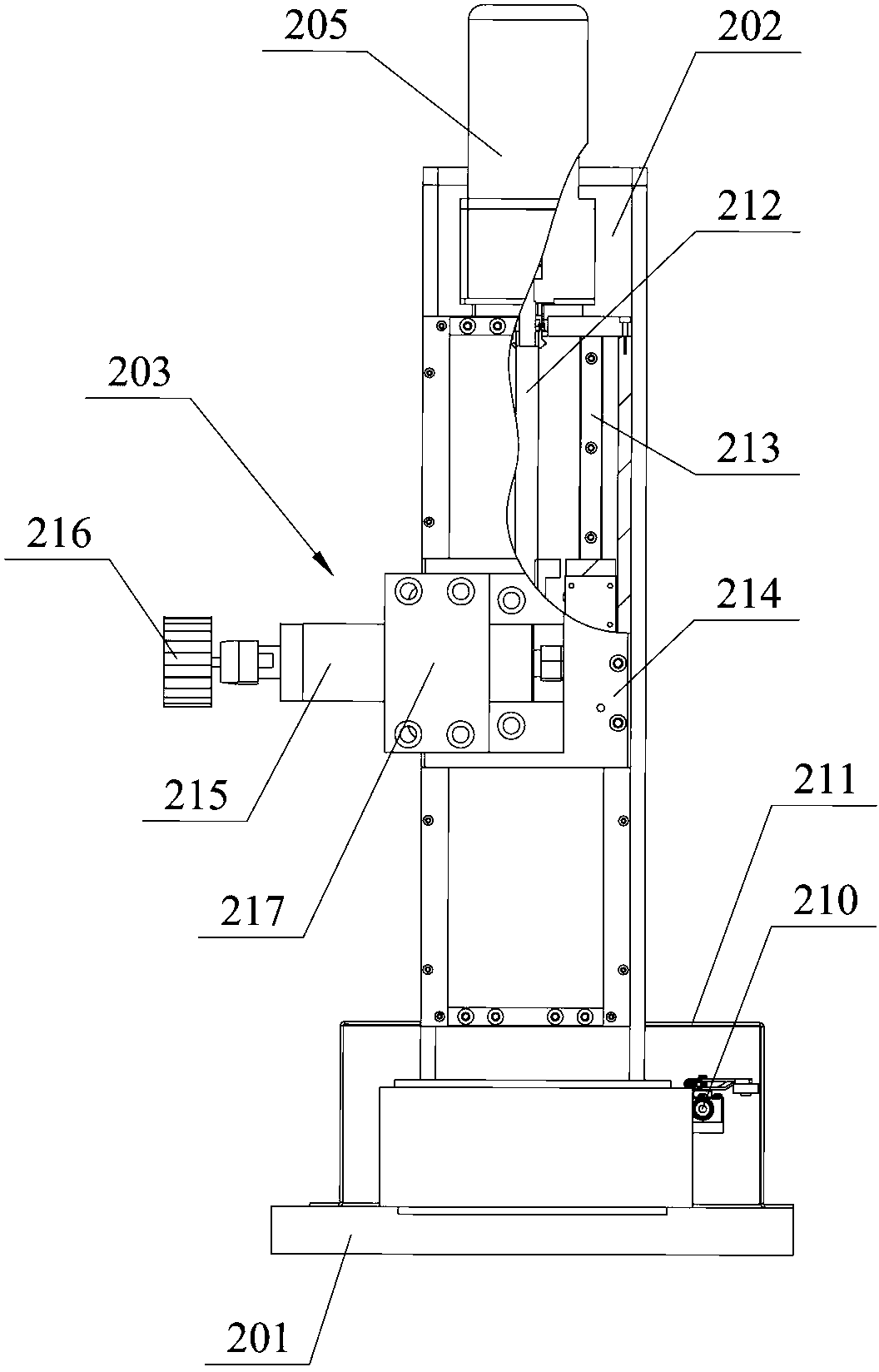

[0029] Embodiment one: see attached figure 1 to attach image 3 shown. A numerical control flat tube grinding machine 2 is used for grinding the end of the extended flat tube 1 in the radiator. The radiator usually has 20 flat tubes 1 welded by two heads. The length of the flat tube 1 is usually 12-9000mm, the width is usually 220mm, and the thickness is usually 20mm, and its surface is coated with galvanized layer. head to remove the galvanizing.

[0030] The numerically controlled flat tube grinding machine 2 includes a connection plate 201, a support beam 202 that is connected to the connection plate 201 by a horizontal movement mechanism and can move horizontally on the connection plate 201, and is connected to the support beam 202 by a vertical movement mechanism. A pneumatic grinder 203 that can move vertically on the support beam 202, a first drive mechanism 204 that drives the support beam 202 to move in the horizontal direction, a second drive mechanism 205 that d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com