Cascade utilization screening method of waste power batteries

A power battery and screening method technology, which is applied in the field of battery technology and energy storage, to achieve the effects of reducing equipment costs, saving clean energy, and simple screening methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

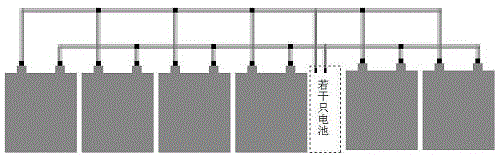

[0020] The present embodiment is a rapid screening method for the cascade utilization of waste power batteries, which includes the following steps:

[0021] 1. Charge the used power battery pack so that its state of charge SOC is 80%. Then disassemble the battery pack, check the appearance of the power battery pack and the single battery under good light, and record it.

[0022] 2. Detect and record the open circuit voltage and internal resistance of each single battery, and compare it with the open circuit voltage and internal resistance of the standard single battery. The tested voltage and internal resistance are used to evaluate the waste power according to the standard single battery charge-discharge curve. Battery pack unit cell capacity.

[0023] 3. Connect the above waste power battery cells in parallel until their open circuit voltages are basically the same, compare with the open circuit voltage of the single cells before parallel connection, and record the voltage ...

Embodiment 2

[0026] The present embodiment is a rapid screening method for the cascade utilization of waste power batteries, which includes the following steps:

[0027] 1. Charge the used power battery pack so that its state of charge SOC is 20%. Then disassemble the battery pack, check the appearance of the power battery pack and the single battery under good light, and record it.

[0028] 2. Detect and record the open circuit voltage and internal resistance of each single battery, and compare it with the open circuit voltage and internal resistance of the standard single battery. The tested voltage and internal resistance are used to evaluate the waste power according to the standard single battery charge-discharge curve. Battery pack unit cell capacity.

[0029] 3. Connect the above waste power battery cells in parallel until their open circuit voltages are basically the same, compare with the open circuit voltage of the single cells before parallel connection, and record the voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com