Strained superlattice tunnel junction ultraviolet LED (light emitting diode) epitaxial structure and production method thereof

An epitaxial structure and superlattice technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as ohmic contact bottlenecks, achieve the effects of reducing resistivity, improving current expansion performance, and enhancing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

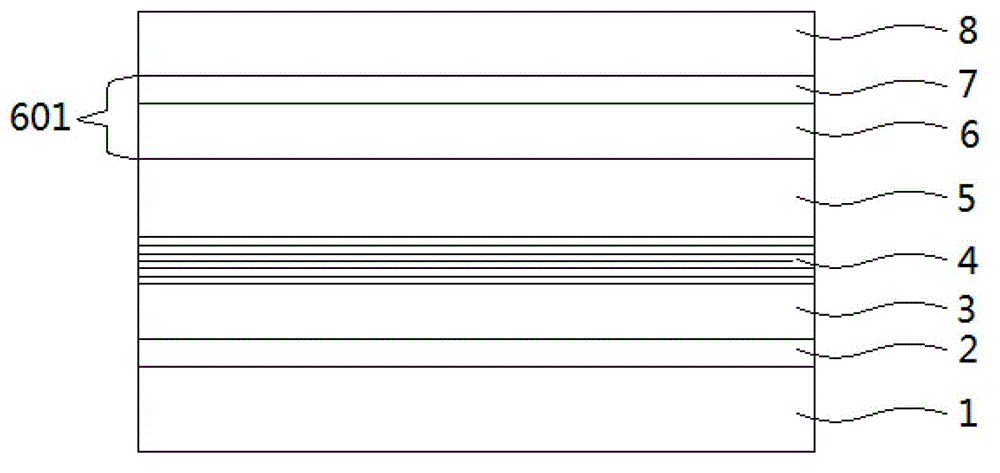

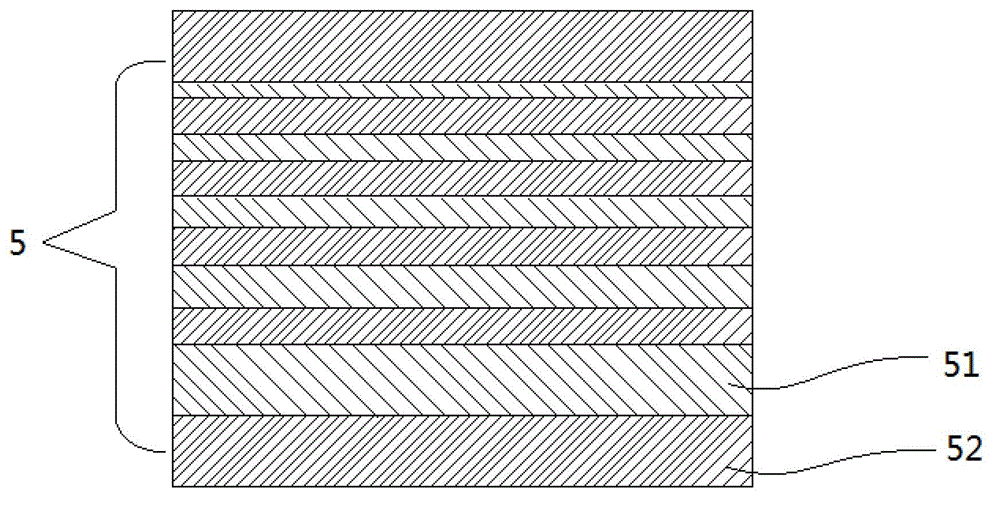

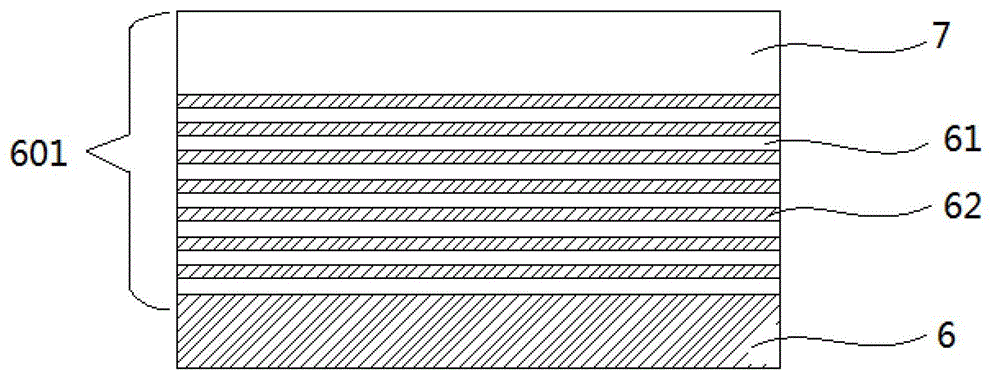

[0030] The invention provides a method for manufacturing a tunnel junction-enhanced ultraviolet LED epitaxial structure, which uses the strain field generated by the superlattice to move the energy band of the AlGaN material in the SSL structure to a low-energy direction as a whole, and forms p-AlGaN / SSL / n*-AlGaN tunnel junction, providing hole carriers. Include at least the following steps:

[0031]Epitaxial growth using MOCVD (Metal-organic Chemical Vapor Depositiong, metal organic compound chemical vapor deposition) or PAMBE system:

[0032] 1) An AlN buffer layer 2 is prepared on the epitaxial substrate 1 with a thickness of 10 nm to 500 nm;

[0033] 2) Growing Si-doped n-type Al on the substrate 1 on which the AlN buffer layer 2 has been grown 0.77 Ga 0.23 N layer 3;

[0034] 3) Five multiple quantum well layers 4 are alternately grown on the n-type AlGaN layer 3; the material of the multiple quantum well layers is Al 0.65 Ga 0.35 N / Al 0.7 Ga 0.3 N;

[0035] 4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com