Rotating electrode device for external electric field deoxidation of metal and slag

A technology of applying an electric field and rotating electrodes is applied in the field of electrochemical deoxidation electrode devices, which can solve the problems of complicated manufacturing process and expensive materials, and achieve the effects of simplifying refining process, reducing production cost and improving productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

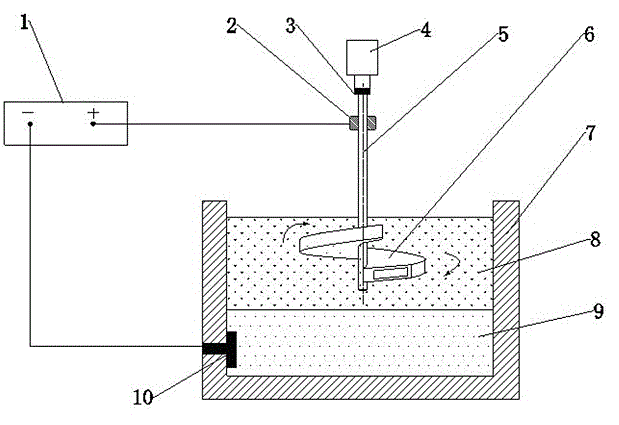

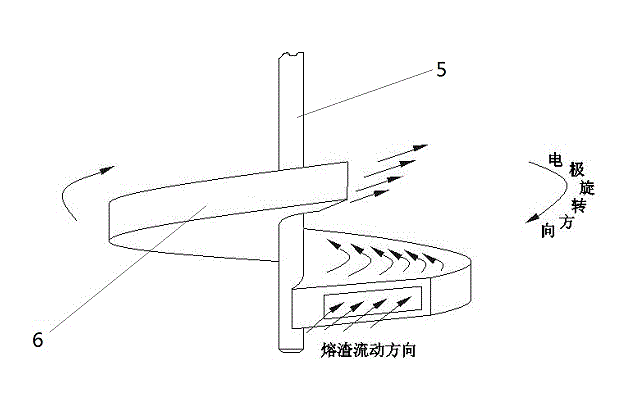

[0027] In this example, see figure 1 and figure 2 A rotary electrode device for deoxidation with an applied electric field between slag and gold, comprising an anode electrode, a cathode electrode 10, a DC power supply 1 and metal wires thereof, one end of the anode electrode is immersed in the molten steel 9 above the molten steel to be deoxidized loaded in the furnace body 7 In the slag 8, the positive pole of the DC power supply 1 is electrically connected to one end of the anode electrode through a metal wire, the cathode electrode 10 is installed on the furnace body 7 as the bottom electrode, and one end of the cathode electrode 10 passes through the shell of the furnace body 7 and is connected to the furnace body to be deoxidized. The molten steel 9 is in direct contact, so that the molten steel 9 to be deoxidized and the cathode electrode 10 together constitute the cathode system of the slag 8, and the other end of the cathode electrode 10 is electrically connected to ...

Embodiment 2

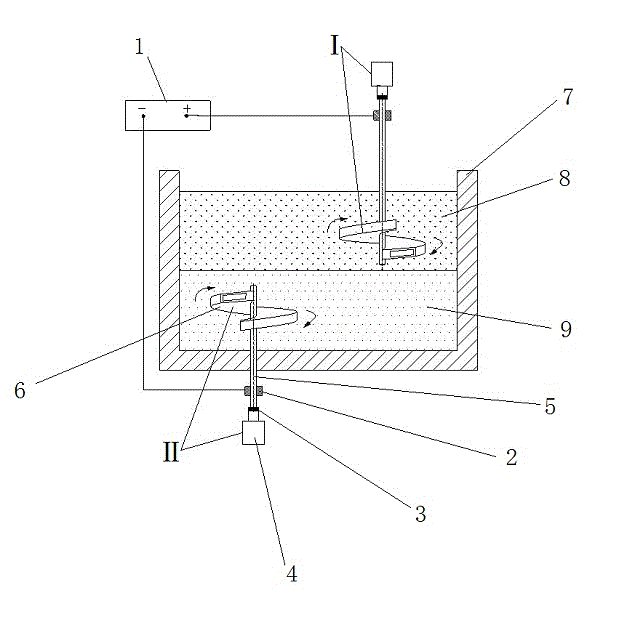

[0031] This embodiment is basically the same as Embodiment 1, especially in that:

[0032] In this example, see image 3 and Figure 4 , the cathode electrode 10 has the same structure as the anode electrode, that is, the cathode electrode 10 is integrally formed by the stirring head part immersed in the molten steel 9 to be deoxidized and the rotating shaft 5 part of the cathode electrode 10 body, and the rotating shaft 5 part of the cathode electrode 10 rotates Installed on the furnace body 7, the cathode electrode 10 can realize controllable spin, and the metal wire is also electrically connected with the rotating shaft 5 of the cathode electrode 10 through the brush 2, and the electric spindle of an adjustable speed motor 4 is coaxially driven The cathode electrode 10, the electric spindle end of the adjustable speed motor 4 is also fixedly connected to the end of the cathode electrode 10 through a coupling 3 made of insulating material, so that the cathode electrode 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com