Preparation method of nanometer titanium dioxide film

A nano-titanium dioxide and thin-film technology, which is applied in the field of nanomaterial preparation and processing research, can solve the problems of difficult film formation, poor substrate adhesion and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

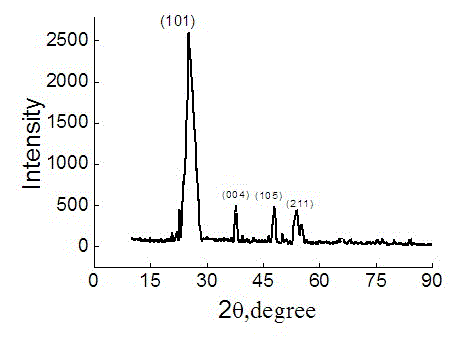

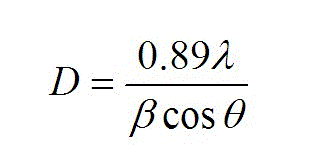

[0024] The invention relates to the preparation of a nano-titanium dioxide film by a sol-gel method.

[0025] The invention is to dry the cleaned glassware and quartz glass substrate in a constant temperature vacuum oven at 100°C. Put analytically pure absolute ethanol and acetylacetone in a reaction kettle and mix evenly, then add ethyl orthotitanate to obtain a uniform and transparent solution. Stir the solution with a constant temperature magnetic stirrer at room temperature. After mixing evenly, continue to drop a small amount of mixed solution of deionized water and absolute ethanol, and stir magnetically to obtain a stable, uniform, clear and transparent yellow gel. After standing still, use a purchased or self-made pulling machine to pull and form a film on a clean quartz glass sheet. Preheating the formed quartz glass sheet in a muffle furnace, followed by calcining and annealing at a preset temperature regime to obtain a nano-titanium dioxide film. The present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com