Secondary drying method for white carbon black

A secondary drying and white carbon black technology, applied in the direction of silica, silicon oxide, etc., can solve the problems of non-compliance with environmental protection and energy saving, low cost and high profit, inability to effectively utilize energy utilization rate, increase production energy consumption, etc. Achieve the effects of reducing difficulty, preventing water absorption, and reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

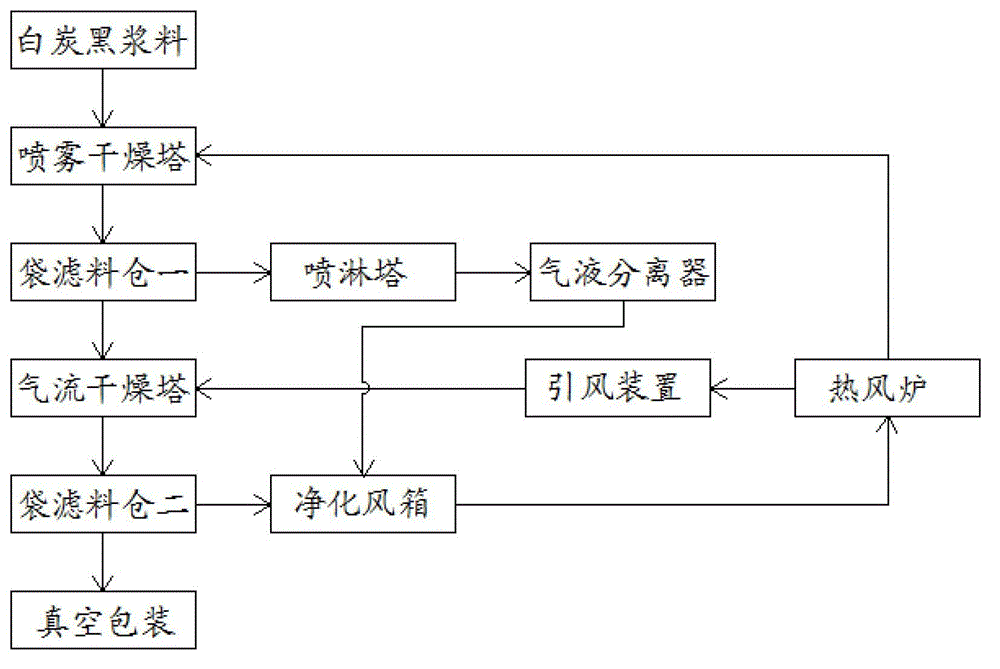

[0020] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0021] see figure 1 Shown, the white carbon black secondary drying method of present embodiment comprises the following steps:

[0022] Step 1. Use the spray drying method to dry the silica slurry for the first time. The hot air temperature required for drying is 450-480°C, the drying time is 20-30s, and the tail gas temperature obtained after drying is 80-90°C;

[0023] Among them, the spray drying can be carried out in the spray drying tower, and the hot air furnace provides the hot air of 450-480°C required for drying into the spray drying tower, and the water content of the silica powder obtained after drying is measured at 4-8wt %, the tail gas obtained after drying contains a large amount of water vapor with a temperature between 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com