Hydraulic jack with automatic speed regulation function

A hydraulic jack and automatic speed regulation technology, which is applied in fluid pressure actuation devices, fluid pressure actuation system components, lifting devices, etc., can solve problems such as insufficient safety, high machining accuracy, and potential safety hazards, and achieve stable and reliable performance , Guarantee work efficiency and ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable the public to fully understand the technical essence and beneficial effects of the present invention, the applicant will describe in detail the specific implementation of the present invention below in conjunction with the accompanying drawings, but the applicant's description of the embodiments is not a limitation to the technical solution. Changes in the form of the inventive concept rather than in substance should be regarded as the protection scope of the present invention.

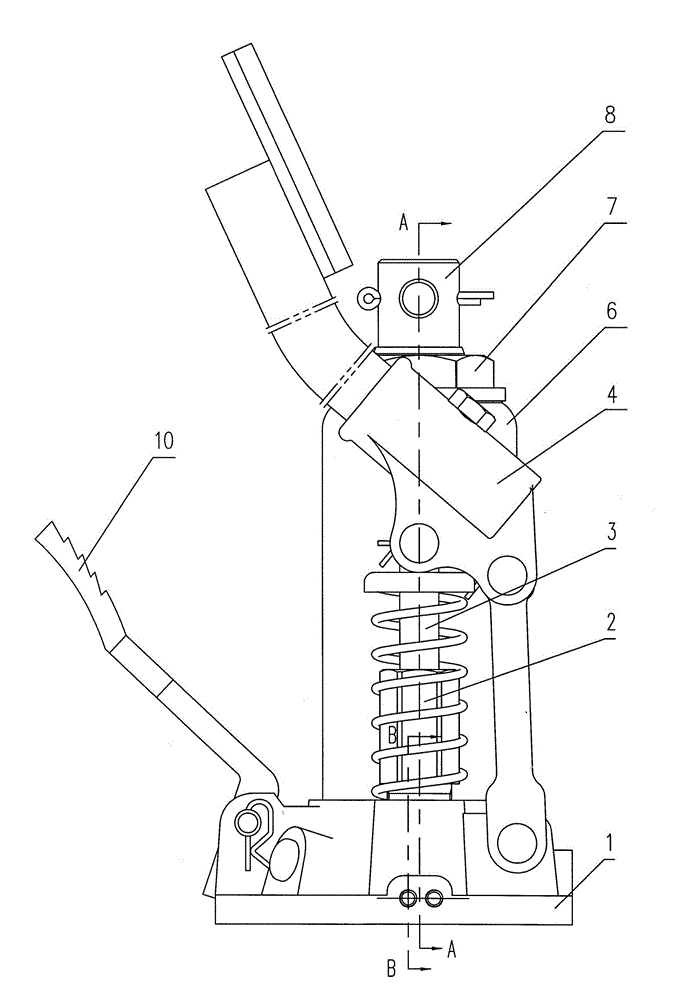

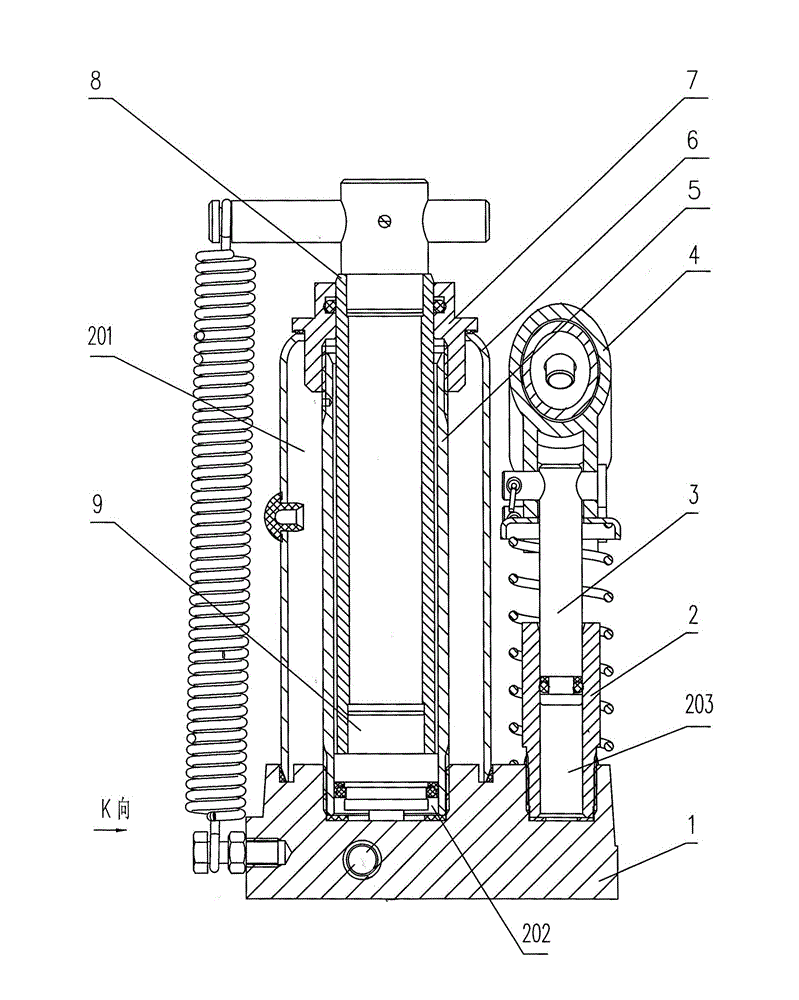

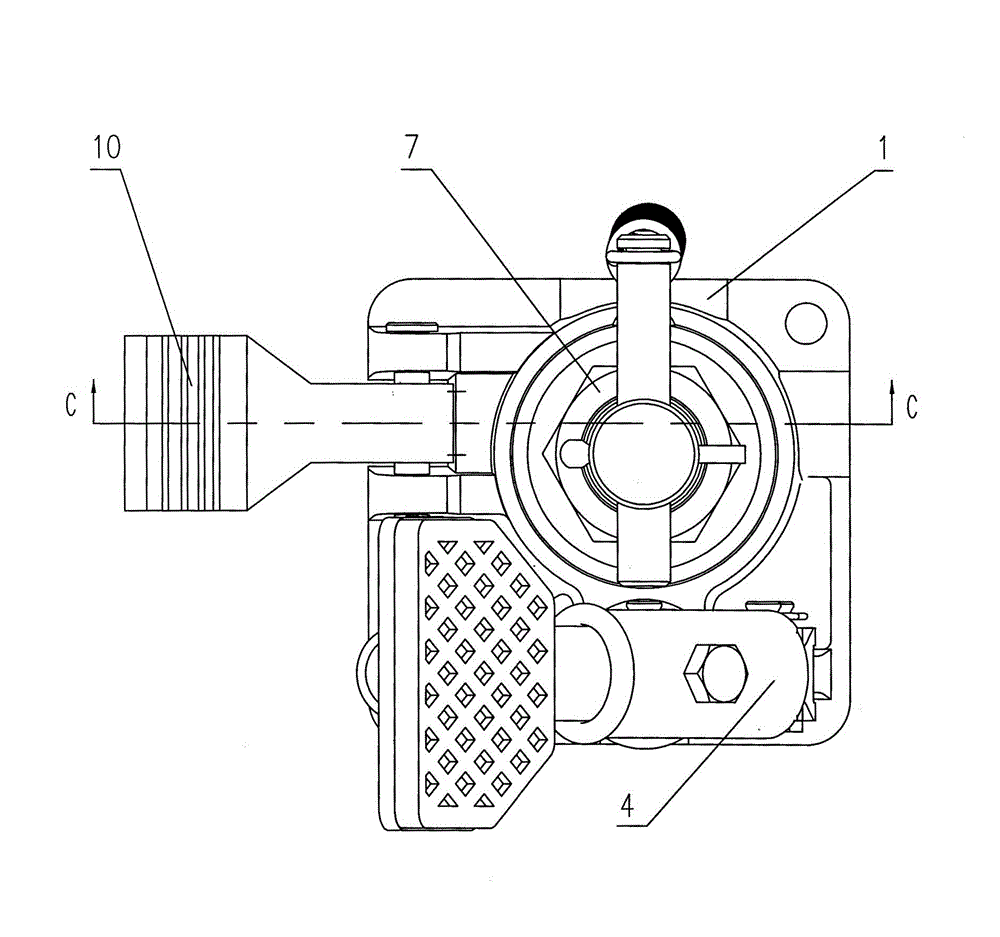

[0022] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7, the present invention relates to a hydraulic jack with an automatic speed regulating function, comprising a base 1, a pump body 2 fixed on the base 1, a pump core 3 arranged in the pump body 2, a pump connected to the base 1 and the pump core 3 The oil pump pedal assembly 4, the oil cylinder 5 and the outer cover 6 fixed on the base 1, the top cap 7 arranged on the oil cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com