Single chip integrated temperature compensation film buck acoustic resonator

A thin-film bulk acoustic wave and single-chip integration technology, which is applied to electrical components, impedance networks, etc., can solve problems such as system errors, and achieve the effects of low bias voltage, overcoming system errors, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

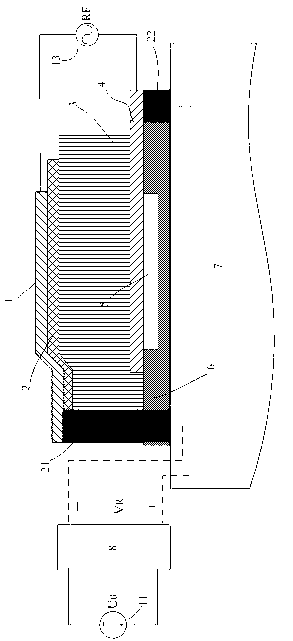

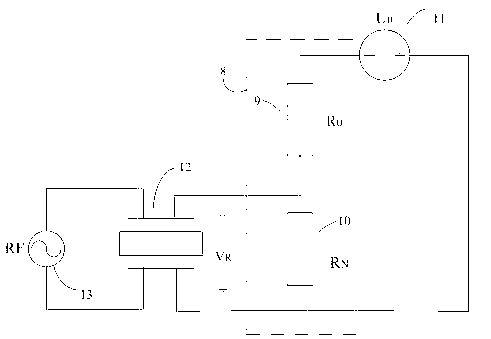

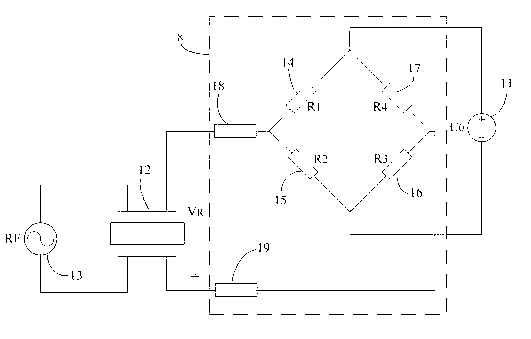

[0019] figure 1 It is a schematic diagram of the single-chip integrated temperature-compensated film bulk acoustic resonator of the present invention. The air gap type FBAR is used here. The DC bias unit 8 is a circuit unit containing a temperature-sensitive resistor, which can be prepared on the surface of the substrate 7 together with other circuits using a common CMOS process, and is connected to an external chip power supply 11 to provide a bias voltage for the thin film bulk acoustic wave resonator, and the output voltage They are respectively added to the upper and lower electrodes of the film bulk acoustic wave resonator. The film bulk acoustic resonator of the present invention is composed of an upper electrode 1, a semiconductor thin layer 2, a piezoelectric layer 3, a lower electrode 4, and an acoustic reflection layer, that is, an air gap 5. The upper electrode (Au or Cr) 1 and the semiconductor thin layer (n-ZnO, N d =10 13 ~10 14 cm -3 ) 2 constitutes a Schottky ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Carrier concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com