a connecting pipe

A technology for connecting pipes and crimping pipes, which is applied in the field of connecting pipes to achieve the effects of easy crimping quality, convenient installation and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

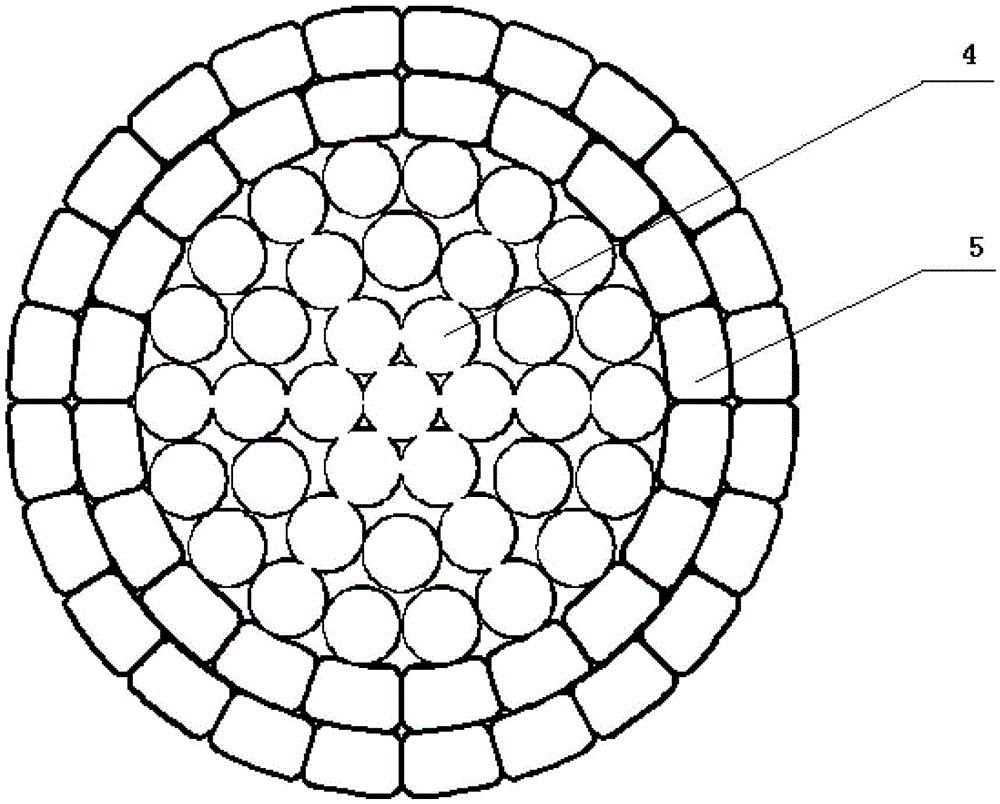

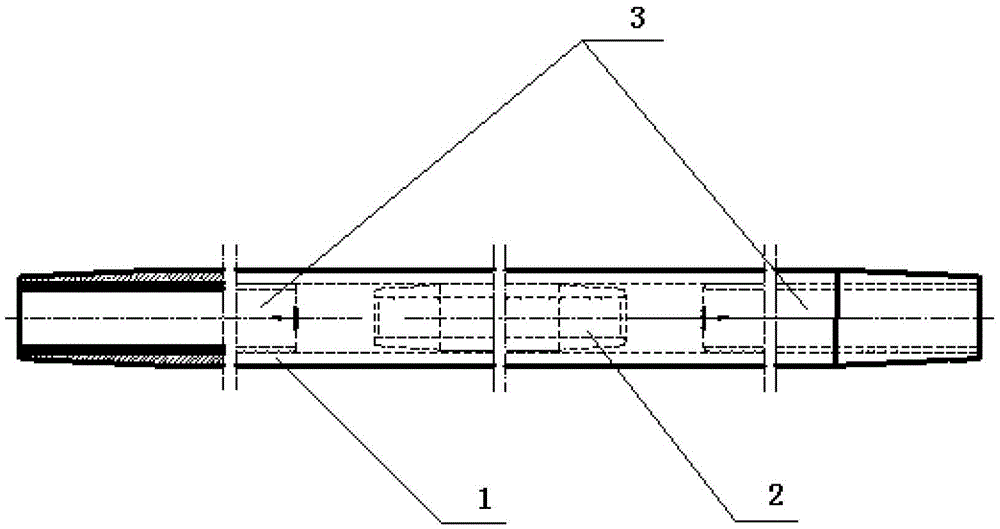

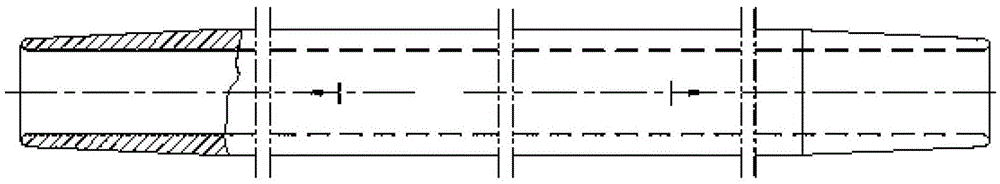

[0033] This embodiment takes the connecting pipe as an example, such as Figure 1 to Figure 5 As shown, the connecting pipe provided by the embodiment of the present invention includes: connecting pipe 1 , crimping pipe 2 , sleeve 3 , aluminum alloy core 4 , and aluminum profile wire 5 .

[0034] Strip the aluminum alloy wire 5 at the two terminals of the aluminum alloy core aluminum wire conductor, expose the aluminum alloy core 4 and put it into the crimping tube 2, and the crimping tube 2 is set in the middle of the connecting tube 1; Sleeve 3 is arranged symmetrically between the end and the gap between the aluminum alloy cored aluminum type wire, and finally the connecting tube 1, crimped tube 2, sleeve 3 and the aluminum alloy cored aluminum type wire are compressed into a hydraulic crimping method. One body, afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com