An aluminum alloy core aluminum type wire conductor large steel anchor type strain clamp

A tension clamp, aluminum alloy technology, applied in the direction of adjusting/maintaining mechanical tension, etc., can solve the problem of increasing the amount of wires and busbars used, the structure size of the tower and the width of the line corridor, increasing the number of split wires, and increasing project investment, etc. problem, to achieve the effect of good conduction current, improve work efficiency, and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

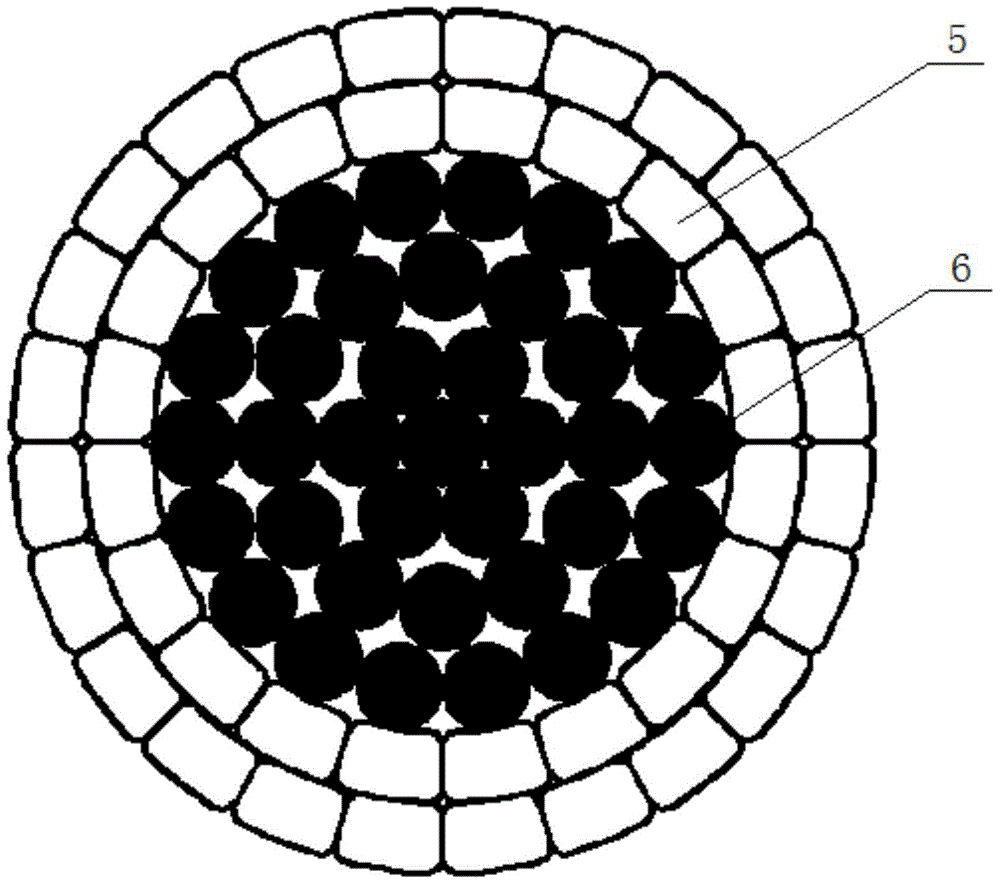

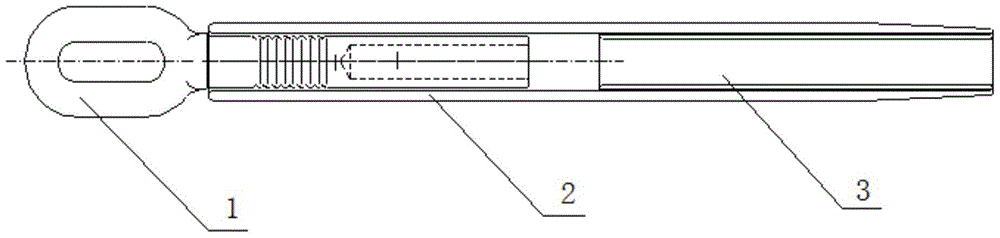

[0034] This embodiment takes the aluminum alloy core aluminum type wire conductor large steel anchor type strain clamp as an example, as Figure 1 to Figure 6 As shown, the aluminum alloy core aluminum type wire lead wire large steel anchor type strain clamp provided by the embodiment of the present invention includes: large steel anchor 1, aluminum tube 2, aluminum sleeve 3, aluminum alloy core aluminum type wire wire 4, aluminum Wire 5, aluminum alloy core 6.

[0035] Such as image 3 As shown, the inner side of one end of the aluminum tube 2 is provided with threads, and the outer side of the other end is provided with chamfers.

[0036] Such as Figure 4 As shown, one end of the large steel anchor 1 is an elliptical ring, the other end is provided with a hole along its axial direction, and a thread matching the al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com