Clostridium for producing acid and application thereof to paper-making wastewater treatment

A technology of papermaking wastewater and Clostridium genus, applied in biological water/sewage treatment, water/sludge/sewage treatment, anaerobic digestion treatment, etc., to achieve good treatment effect, enhanced recovery efficiency, and strong acid production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Screening of strains

[0034] Using sodium formate, sodium acetate, and methanol as substrates to enrich anaerobic bacteria from the sediments of straw pulp and papermaking wastewater: Take 5ml of straw pulp and papermaking wastewater sediments and add 45ml of methane to the anaerobic incubator for enrichment culture. base in a 100ml anaerobic bottle. Cultured at 30°C for 10 days, then transferred to a 100ml anaerobic bottle containing 45ml of methane-enriched medium in an anaerobic incubator according to 5% of the inoculum, and cultured at 30°C for 10 days, and then according to 5 % of the inoculum was transferred to a 100ml anaerobic bottle with 45ml of methane-enriched medium in an anaerobic incubator, cultured at 30°C for 10 days, and then transferred to an anaerobic incubator according to 5% of the inoculum Connected to a 100ml anaerobic bottle containing 45ml of methane-enriched medium;

[0035] Among them, the formula of methane enrichment medium is:...

Embodiment 2

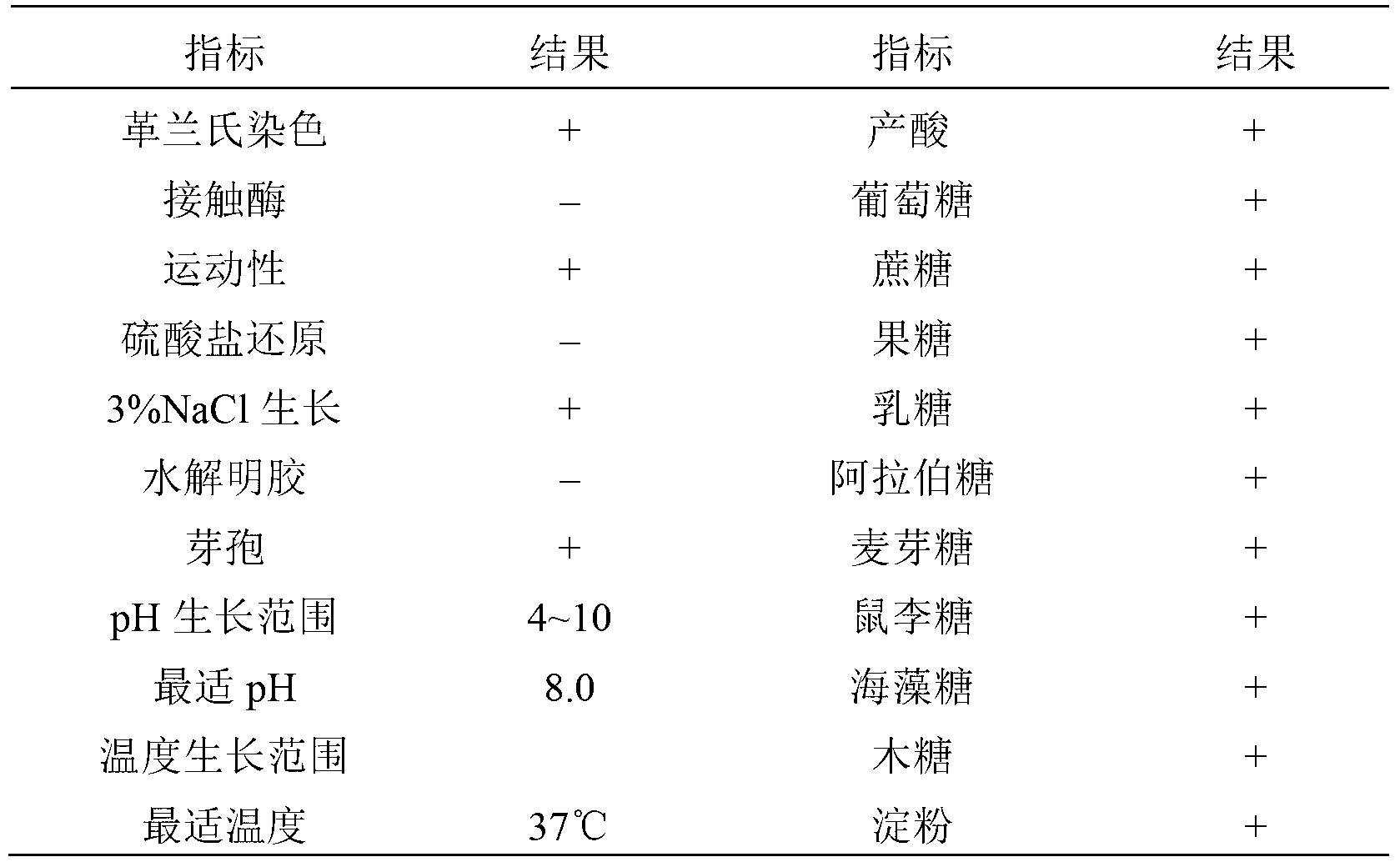

[0042] Example 2: Identification of YC3 strain

[0043] Genome extraction and 16S rDNA analysis: Take 1.5 mL of YC3 strain culture, centrifuge at 6000g for 2 minutes; use Promega genome extraction kit for genome extraction according to the instructions. Finally redissolve in 100 μL of TE buffer. Using the extracted genomic DNA as a template, PCR amplification was performed using the bacterial universal primers 27f and 1492r synthesized in BGI, and the following reagents were mixed in sequence in a 50 μL reaction system: 35 μL H 2 O, 5 μL of 10-fold concentration PCR reaction buffer, 4 μL of 25 mmol L -1 MgCl 2 , 1 μL of the mixture of 4 kinds of dNTPs, 0.5 μL of upstream primer, 0.5 μL of downstream primer, 0.5 μL of template DNA, which is the genomic DNA of YC3, and 0.5 μL of Taq DNA polymerase. The product was sequenced after PCR reaction. The sequence is shown in SEQ ID No.1.

[0044] By consulting the relevant international gene bank at the National Center for Biotech...

Embodiment 3

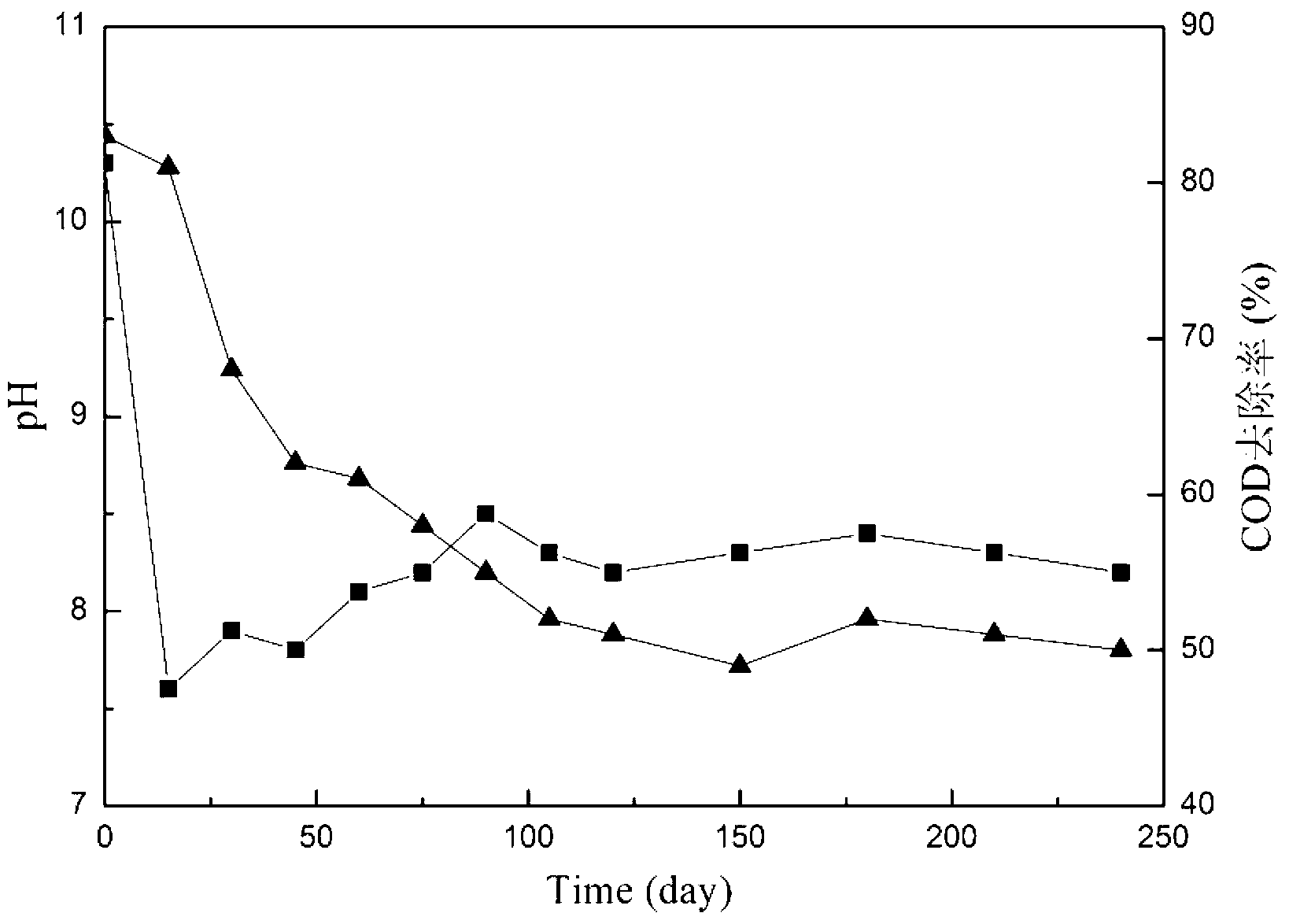

[0052] Example 3: Method for treating papermaking wastewater by Clostridium sp. strain YC3: the initial bacterial population inoculation amount is 40% (volume percentage)

[0053] Take the acid-producing Clostridium sp. strain YC3CCTCC NO: M2012555 and inoculate it in a 100 mL anaerobic bottle containing 50 mL of liquid seed medium under sterile conditions. Cultivate until OD reaches 9-10 to obtain first-class seeds;

[0054] Among them, the liquid seed medium formula is: 1 liter of distilled water contains 10 grams of glucose, 5 grams of yeast powder, 2 grams of peptone, 5 grams of NaCl, 2.5 grams of KH 2 PO 4 , 2 g MgSO 4 , pH9.0, divided into anaerobic bottles in an anaerobic incubator, sterilized at 115 ℃ for 30 minutes;

[0055] With an inoculum volume of 5% by volume, the above-mentioned first-class seeds were inoculated into a 100ml anaerobic bottle containing 50ml of liquid fermentation medium, and at 30-37°C, the anaerobic culture was allowed to stand until the OD ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com